|

| Elliott Sound Products | Beginners' Guide to Transformers - Part 2 |

Main Index Main Index

Articles Index Articles Index

|

For those brave souls who have ploughed their way through the first section - I commend you! As you have discovered, transformers are not simple after all, but they are probably far more versatile than you ever imagined. They are, however, real world devices, and as such are prey to the failings of all real components - they are imperfect.

This section will concentrate a little more on the losses and calculations involved in transformer design, as well as explain in more detail where different core styles are to be preferred over others. Again, it is impossible to cover all the possibilities, but the information here will get you well on your way to a full understanding of the subject.

The first topic may seem obvious, but based on the e-mails I get, this is not the case. Transformers can have multiple windings, and these can be on the primary or secondary. Windings can be interconnected to do exciting and different things, but from a safety perspective it is imperative that primary and secondary windings are kept segregated.

There are several references to 'shorted turns' within this article. If any two turns of a winding short to each other, the current flow is limited only by the DC resistance of the shorted section of the winding. The current flow can be enormous, and with even one shorted turn, the transformer is no longer serviceable and must be discarded or rewound. No shield or other conductive material may be wrapped around the winding and joined, as this creates a shorted turn capable of possibly hundreds of amperes. The exception to this is the magnetic shield sometimes used with E-I laminated transformers, but this is wrapped around the entire transformer (outside the core), and is not considered as a 'turn' as it is not in the winding window with the primary and secondary.

It is also worth noting that a transformer behaves quite differently depending upon whether it is driven from a voltage source (i.e. very low impedance, such as a transistor amp or the mains) or a current source or intermediate impedance. This will be covered in a little more detail further on in this article.

Three things that you need to keep in mind - always ...

Note: This is the practical case, assuming normal usage of the transformer. A theoretical 'ideal' transformer having zero winding resistance will have constant flux, regardless of load - provided the input voltage is constant. Since the real world has real-world transformers, the flux decreases slightly with load due to the voltage lost across the transformer's primary winding. This is explained in more detail below.

Before reusing any transformer - especially if designed for a different purpose, voltage or frequency - you need to check that it will not draw excessive magnetising current. Worst case is with no load, and the current should be measured and the temperature monitored for long enough to be certain that the transformer does not get so hot that it's uncomfortable to hold. If the idle temperature rise is more than about 25°C the transformer should not be used. Bear in mind that some small transformers run rather hot all the time, so on occasion you may have to make a value judgement based on experience.

Many transformers are supplied with two (or more) secondaries. In many cases, the data sheet will indicate that the windings may be connected in parallel or series. For example, a toroidal transformer may be rated at 2 x 25V at 5A (250VA). With the windings in parallel, the available current is 10A, but only for a single voltage of 25V AC. Connect the windings in series, and you get 50V at 5A, or by referencing the centre tap to earth, the familiar 25-0-25 designation.

Figure 8.1 - Windings in Series and Parallel

There are some rules that apply to winding interconnections - if you break them, you may break your transformer as well. Note the dots on the windings - this is the traditional way to identify the start of a winding, so that the phase may be determined.

Autotransformers are covered in Section 19 below. These are a special case of windings in series, and are commonly used to obtain a reduced voltage with the highest possible efficiency and lowest cost.

Antiphase wiring will not harm a transformer when wired in series (although the zero volts output for equal windings is somewhat limited in usefulness). Parallel antiphase connection will destroy the transformer unless the fuse blows - which it will do mightily. Always use a fuse when testing, as a simple mistake can be rather costly without some form of protection for the transformer and house wiring!

Windings may be connected in series regardless of voltage. The maximum current available is the rating specified for the lowest current winding. Windings may be connected so as to increase or decrease the final voltage. For example, dual 25V windings may be connected so as to produce 50V or zero volts - although the latter is not generally useful :-)

When windings are connected in phase the voltages add together, and if connected out of phase, they subtract. A 50V, 1 amp winding and a 10V 5 amp winding may therefore be connected to provide any of the following ...

The above example was used purely for the sake of example (such a transformer would not be useful for most of us), but the principle applies for all voltages and currents. Series connections are sometimes used in the primaries as well, mainly for equipment destined for the world market. There are several common mains supply voltages, and primary windings are connected in various combinations of series and parallel to accommodate all the variants.

Parallel connection of transformer windings is permitted in one case only - the windings must have exactly the same voltage output, and must be connected in phase. Different current capacities are not a problem, but it is rare to find a transformer with two windings of the same voltage but different current ratings.

Even a 1V difference between winding voltages will cause big problems. A typical winding resistance for a 5A winding might be 0.25 ohm. Should two such windings be connected in parallel, having a voltage difference of 1V, there will be a circulating current limited only by the resistances of the windings. For our example, the total winding resistance is 0.5 ohm, so a circulating current of 2A will flow between the windings, and this is completely wasted power. The transformer will get unexpectedly hot, and the maximum current available is reduced by the value of the circulating current.

Should the windings be connected out of phase, the circulating current will be possibly 100A or more, until the transformer melts or the fuse blows. The latter is generally to be preferred.

The transformer manufacturer's specifications will indicate if parallel operation is permitted. If you are unsure, measure the voltages carefully, and avoid parallel connection if the voltages differ by more than a couple of hundred millivolts. There will always be a difference, and only the manufacturer's winding tolerances can predict what it will be. With toroidal transformers, the windings are often bifilar, meaning that the two windings are wound onto the transformer core simultaneously. The tolerance of such windings is normally very good, and should cause no problems.

In Section 1, I described a very basic push-pull valve output stage. Now it is time to examine this a little more closely. We shall use the same voltages as were obtained in the basic description of Section 1 - an RMS voltage of 707V. It must be said that the following is not intended to be an accurate representation of valves, as the losses in real life are somewhat higher than indicated here. This is for example only. We shall also take the (typical) losses as 10%, and adjust the secondary impedance accordingly.

A valve (tube) amplifier is required to drive an 8 ohm loudspeaker. The primary impedance (called the Plate-Plate impedance for a push-pull amplifier) is 6,000 Ohms, and the supply voltage is 600V. Allowing for losses of 100V across each valve, the maximum voltage swing on the plates (anodes) of the valves is 1kV p-p (or effectively 2kV peak to peak on the transformer primary). What is the output power?

Secondary impedance will be 7.2 ohms, based on the 10% loss ...

Zs = 8 / 1.1 = 7.2 ohms

The impedance ratio is calculated first ...

Z = 6,000 / 7.2 = 833

The turns ratio may now be determined

N = √833 = 28.8 (29:1)

The voltage ratio is the same as the turns ratio, so the peak to peak voltage to the speaker is

Vs (p-p) = Vp / N = 2,000 / 29 = 69V

To convert this to RMS ...

Vp = 1/2 Vp-p = 34.5V

RMS = peak × 0.707 = 24V

Power is therefore 24² / 8 = 72W

Notice that at each calculation, the figures were rounded to the closest (or next lowest) whole number. This was for convenience, but the way I did it also gives a conservative rating that is more likely to be met in practice.

Ouch! Sorry, that was a bit nasty for this time of day  .

.

A bit nasty or not, it is a reasonable representation of the reality of an output transformer design, but naturally real (as opposed to my 'invented' figures) will be substituted. Typically the losses across the output valves will often be far greater than indicated here. but that depends on the valves used (and the topology - triodes behave very differently from pentodes or tetrodes).

Just to complete this section and to put the above into perspective, I have included a few figures (taken from the 1972 Miniwatt Technical Data manual) for the EL34/ 6CA7 power pentode - one of the world's all-time favourite output valves.

| Class | Mode 1 | Plate Volts |

Plate Current | Screen Volts | Screen Current |

Grid Bias | Load Impedance | Power Output |

Comments |

| Class-A | S-E | 250 | 100 | 265 | 15 | -13V | 2,000 | 11W | Plate supply = 265V, THD 2 10% |

| Class-AB | P-P | 375 | 2 x 75 3 2 x 95 |

365 | 2 x 11.5 2 x 22.5 | -19V | 3,400 (p-p) 4 | 35W | Cathode bias resistor 130 ohms, common screen resistor, 470 ohms, THD 5% |

| Class-B | P-P | 775 | 2 x 25 2 x 91 |

400 | 2 x 3.0 2 x 19 | -39V | 11,000 (p-p) | 100W | Plate supply, 800V, THD 5% |

| Class-A (Triode) | S-E | 375 | 70 | - | - | -25V | 3,000 | 6W | Cathode bias resistor 370 ohms, Screen tied to plate, 400V plate supply, THD 8% |

| Class-AB (Triode) | P-P | 400 | 2 x 65 2 x 71 |

- | - | -28V | 5,000 (p-p) | 16W | Screen tied to plate, Cathode bias resistor 220 ohms, THD 3% |

1 S-E: Single Ended, P-P: Push-Pull 2 THD - Total Harmonic Distortion (this is for the valves only, and does not include transformer distortion) 3 First figure is no load, second figure is full power 4 p-p: Plate to Plate impedance

As can be seen quite readily, the distortion of the S-E configurations is much worse than the push-pull versions. Not only that, but (to maintain relevance :-) the transformers are larger and harder to design, and even then will be worse than their push-pull counterparts. In the maximum efficiency configuration, power output is 100W, and distortion is still lower than for either of the single ended configurations. The losses across the output valve in this mode are about 58V, but are considerably higher for any of the cathode biased versions - as one might expect.

This will be revisited in another article on the design of valve amplifiers.

It is very important that the core does not saturate (see below), since there will be no continuous sinusoidal variation of flux, greatly reduced back EMF, and excessive current will be drawn - especially at no load. The final design of any transformer is a huge compromise, and there is a fine line between a transformer that will give acceptable regulation and one that gets too hot to touch at no load.

Somewhat surprisingly, the flux density in the core actually decreases with increased load current drawn from the secondary. Even though the primary is drawing more current, this is transferred to the secondary and thence the load - it does not cause the flux density to increase. The flux density decreases largely due to primary resistance, which causes the effective primary voltage to decrease. Any voltage lost to resistance (remember Ohm's law?) is voltage that is 'lost' to the transformer, and serves no function in the transformation process. It does cause the transformer to get hot (or hotter) than at no load. See the next section for more details on this.

Also, the normal variation of mains voltage must be allowed for. A transformer running at the very limit of saturation at nominal supply voltage will overheat if the mains is at the upper (normal) limit. A transformer that is designed to run at the limit will have superior regulation compared to a more conservative design, but this is of little consequence if it fails in normal use due to overheating.

For audio transformers, there are even more compromises.

As discussed earlier, a transformer is a real component, and therefore has losses. These are divided into two primary types, but there are other 'hidden' losses as well. All losses reduce efficiency, and affect frequency response. The low frequency limit is determined by the primary inductance, and this is proportional to the area (and consequent mass) of the transformer core. High frequency losses are caused by eddy currents in the core (see below), and by leakage inductance and winding capacitances.

None of these can be eliminated, but by careful selection of core material, winding style and operational limits, they can be reduced to the point where the transformer is capable of doing the job required of it.

Core losses are partly the result of the magnetising current, which must keep forcing the magnetic field in the core to reverse in sympathy with the applied signal. Because the direction of flux is constantly changing, the transformer core is subject to a phenomenon called hysteresis, shown in Figure 11.1

Figure 11.1 - The Hysteresis Loop

When the magnetomotive force is reversed in a magnetic material, the residual magnetism (remanence - also known as remnance in some cases) in the core tries to remain in its previous state until the applied flux is too great (coercivity). It will then reverse, and the same situation will occur twice for each cycle of applied AC. The power required to force the flux to change direction is the hysteresis loss, which although usually small, is still significant. I am not about to go into great detail on this, but a Web search will no doubt reveal more information than you will ever need.

Figure 11.2 - B-H Curve

As can be seen from the two magnetic field drawings, the flux density (B) is dependent upon the applied magnetic field strength (H). For the example shown, the 'knee' of the curve coincides with the point where permeability starts to fall. Above this, a progressively larger change in the magnetic field is required to increase the flux density. This is saturation, and most transformers will be designed to operate at or below the knee. Above the knee is dangerous, as a small increase in applied voltage will not produce the required increase in back EMF, and the primary current will increase disproportionately to the rise in voltage. In other words, the transformer will be too sensitive to applied voltage, and will possibly self destruct if the mains voltage were even slightly higher than normal. If such a transformer is wound for 60Hz but used at 50Hz, failure is inevitable.

Figure 11.3 - Cutaway View of a Transformer

The transformer shown is a 'split bobbin' type, having separate sections on the former for the primary and secondary windings. This reduces the capacitance between windings, and also provides a safety barrier between the primary and secondary. For some applications, this is the only winding method that meets safety standards. It is also very simple to add an electrostatic shield between the windings - a flat plate of thin metal is cut so that it can be slipped over the bobbin, and the ends are insulated so that it does not create a shorted turn. This is connected to earth, and prevents noise from being capacitively coupled between windings. The shield would logically be placed on the secondary side of the bobbin divider for safety.

In addition, there are so-called 'eddy current' losses. These are small circulating currents within the magnetic core, as shown (exaggerated) in Figure 11.4, and these cause the core material itself to get hot. Each of these eddy current loops acts as a tiny shorted turn to the transformer, and to reduce the effect, the core is laminated - i.e. made from thin sheets of steel, insulated from each other. The thinner the laminations, the smaller are the eddy current losses, but they will never be eliminated. Eddy current losses increase with frequency, requiring different techniques for high frequency operation, and are the major contributor to the iron losses in any transformer.

Figure 11.4 - Eddy Currents in Laminations

The eddy currents are shown for three lamination thicknesses. Although not shown (for the sake of clarity), the current loops are constantly overlapping, and are effectively infinite in number. The thick laminations allow the loops to be larger, and therefore the lamination section is cut by more magnetic 'lines' of force, so the currents (and losses) are larger. For high frequencies (above 10kHz), it is generally not possible to make laminations thin enough to prevent the losses from becoming excessive, and ferrite materials are preferred. These effectively have a huge number of incredibly small magnetic particles, all insulated from each other, and eddy current loops are very small indeed. Even so, ferrite materials are normally specified up to a few hundred kilo-Hertz for power applications before the losses become too great again.

Iron losses of both types are the primary source of losses in any transformer that is operating at no load or only light loading. At no load, the core flux density is at its maximum value for any given applied voltage / frequency combination. Power transformers are usually designed to operate below the knee of the saturation curve (this is essential with toroidal types), with sufficient safety margin to ensure that the core can never saturate.

Saturation involves a dramatic loss of permeability (and therefore inductance), and causes the primary current to rise disproportionately to an increase of voltage. Where one would hope for a nice sinusoidal current waveform with low distortion, significant current waveform distortion occurs once the core starts to saturate.

As a load is drawn from the secondary, the primary must supply more current, and this means that the resistance of the primary winding becomes significant. Any voltage 'lost' to winding resistance is effectively no longer part of the applied voltage, so core flux is reduced.

For example, if the primary resistance is 5 ohms and the loaded primary current is 2A at 230V, 10V is lost across the winding resistance, so the effective primary voltage is reduced to 220V. This reduces the magnetising current, but the effect is not linear. It depends a lot on how close to saturation the core operates with no load, and the difference may be anything from minimal to significant, depending on the design.

Following on from the previous point, the voltage lost to winding resistance is copper loss, and all such losses must be dissipated as heat. Consider the same transformer as above at idle, with 230V on the primary. The primary resistance may be in the order of 5 ohms (a transformer of around 300VA), and the idle current perhaps 20mA. The loss is determined by the normal power formula, and in this case is ...

P = I² × R = 0.02² × 5 = 2mW

V = R × I = 5 × 0.02 = 100mV

For all intents and purposes, the full 230V is applied to the primary. When the transformer is loaded, this changes. Let's assume 2A primary current and look at the figures again ...

P = I² × R = 2.00² × 5 = 20W

V = R × I = 5 × 1.00 = 10V

Now, the effective primary voltage is only 220V, because 10V is 'lost' due to winding resistance. Naturally, if the voltage is lower, the flux density must also be lower. The power lost in the primary must be dissipated as heat, so the transformer will start to get hot. Remember that there will be additional losses in the secondary that add to the heat that must be dissipated.

Minimising copper loss in both primary and secondary is essential, but there are limits to what can be achieved. These are imposed by the available space for the winding, and just how much copper the manufacturer can get into that space. Allowance must still be made for insulation and manufacturing tolerances.

You may see that in Figure 11.3 the windings are shown stacked directly on top of each other. Surely a more efficient winding can be made by making use of the 'valleys', minimising the winding height and allowing heavier windings. Ah, if only life were that simple! The windings are traditionally made from left to right, then right to left, so the turns in each layer are at a slight angle relative to the layer below or above. It is therefore not possible to utilise the inter-turn winding valleys properly, and if you were to wind a transformer based on the erroneous assumption that this would work, the finished winding would not fit into the window.

For the normal layered construction (i.e. primary closest to the core, and secondary over the top), we also have to allow for insulation between primary and secondary, and in some cases additional insulation is used between layers of larger transformers because of the large voltage difference between the outer limits of each winding. These are another set of compromises that must be made, all of which mean that the windings must be thinner than we might like, and thus the losses are increased.

Because any length of wire has resistance, there will always be winding resistance. The greater the resistance for a given current, the more power is dissipated as heat - this is a complete loss. At no load (provided saturation is avoided), there is virtually no loss, since the currents are low, but as secondary current increases, so too do the copper losses.

The current density allowable for the copper windings is a somewhat variable figure. Current density refers to the current in Amps per unit of wire area, for example 2.565A/mm² (a reference standard used in Australia and presumably elsewhere as well). Increasing the current density has a major effect - it causes the wire to get hotter for a given current. Side forces caused by the magnetic fields generated between each turn need to be considered in large power distribution transformers, especially under short-circuit conditions where the forces can be destructive. There is no such thing as a 'typical' current density, because different manufacturers use different design criteria. In general, it's better to keep current density below 3.0A/mm² and 2.5A/mm² is even better. Naturally, a lower current density means that the transformer is larger and heavier than one operated at a high density, and ultimately it's all a trade-off against temperature rise and cost.

For many transformers used in audio, the current density can often be expected to be somewhat higher than one might prefer. This is because exceptionally high efficiency is not needed, and the demand from normal music programme material has a rather low average value. As a result, transformers for power amplifiers (for example) are rarely operated at continuous full load - they are more likely to be run with short term overloads, but at perhaps 50% full load on a long-term average basis when operated at the onset of clipping with 'typical' programme material.

I took a few measurements on transformers I have to hand, and found that with toroidals in particular, there is a common trend. The current density of the primary is comparatively low, averaging around 2.1A/ mm², while the secondaries all used a much higher current density - around 4.8A/ mm². This makes sense, because the secondary is on the outside and has the advantage of better cooling than the primary. The primary winding can only get rid of heat through the secondary winding, which stands between the winding and cooling air. This may be less of a problem with E-I cores, because the core itself acts as a heatsink (although not a very efficient one).

Small transformers are likely to be operated at higher current densities than larger ones, and this is reflected in that fact that they get hotter and (almost always) have worse regulation. A current density of up to 3.5A/ mm² is typical of some smaller transformers. One reason for this is that it becomes extremely difficult to fit the number of turns needed into the space allowed. The main reason is that the insulation requirements don't change, so insulation takes a larger percentage of the winding space with small transformers than with larger examples.

Guitar amplifiers (and any other that is regularly operated into heavy distortion) should have a transformer rated for at least double the nominal 10% THD output power. Thus a nominal 100W amp needs a 200VA transformer as the bare minimum. This is especially important for valve amplifiers, because they are already operating in a hotter than normal ambient due to the heat from the valves themselves. Regrettably, this is regularly ignored, with the result that some amps have a reputation for burning out mains transformers.

Note that skin effect can be ignored for mains frequency transformers (50/ 60Hz), but is a significant problem with high frequency switching transformers. These are not covered here - the information in this article is based almost exclusively on transformers used at low frequencies where skin effect has little or no impact.

Copper loss is the primary source of loss at any appreciable power from a transformer. Conventional rectifiers as used in semiconductor amplifier power supplies cause the resistance to be more significant than would otherwise be the case. See Linear Power Supply Design for more details on these losses, which cause regulation to be much worse than expected.

Ultimately, copper losses limit the power available from a transformer. Since all copper loss results in heat, this becomes a limiting factor, so once you reach the point where the temperature rise cannot be limited to a safe value, the size of the core must be increased. This allows the manufacturer to use fewer turns per Volt, and the larger core has more space for the windings. The wire size can therefore be increased, so copper losses are brought back to the point where overheating is no longer a problem. This process continues from the smallest transformers to the largest - each size is determined by the VA rating and allowable temperature rise.

Keeping a transformer as cool as possible is always a good idea. At elevated temperatures the life of the insulation is reduced, and the resistance also increases further because copper has a positive temperature coefficient of resistance. As the transformer gets hot, its resistance increases, increasing losses. This (naturally) leads to greater losses that cause the transformer to get hotter. There is a real risk of drastically reduced operational life (or even localised 'hot-spot' thermal runaway) if any transformer is pushed too far - especially if there is inadequate (or blocked) cooling.

It is generally accepted that any transformer will have one part of the winding that (for a variety of reasons) is hotter than the rest. It's also a rule of thumb that the life expectancy of insulation (amongst other things) is halved for every 10°C (some claim as low as 7°C) temperature increase. When these two factors are combined, it is apparent that any transformer operated at a consistently high temperature will eventually fail due to insulation breakdown. The likelihood of this happening with a home system is small, but it's a constant risk for power distribution transformers. Despite all this, mains frequency iron cored transformers typically outlast the product they are powering, and even recycled transformers can easily outlast their second or third incarnation. Once a transformer is over 50 years old I suggest that the chassis be earthed, as the insulation can no longer be trusted at that age.

Fan cooling can increase the effective VA rating of a transformer significantly, but does not improve regulation. Large power distribution transformers are almost always oil cooled, and they are now starting to use vegetable oils because they are less inclined to catch on fire, and pose minimal environmental impact should there be a coolant leak or other major fault.

The skin effect is well known (and exploited by snake-oil cable makers), but has little or no relevance for audio frequencies. With switchmode power supply transformers it is a real problem, and the most common way to minimise the influence is to use multiple small (insulated) wires in parallel - typically bundled and twisted into a single rope-like strand. This is commonly referred to as Litz wire, and its use reduces skin effect losses because the wire bundle has a comparatively large surface (or 'skin') area.

You don't normally hear much (if anything) of the so-called proximity effect, but it refers to the (often chaotic) disturbance of the current flow in a conductor when that conductor is immersed in an intense magnetic field. For small transformers (below perhaps 2kVA), there is little evidence that it causes any problems, but in larger transformers it can cause localised heating because the current is forced to use far less of the wire's cross section than expected. Use of Litz wire again reduces the proximity effect, and may be crucial to prevent failure. Proximity effect may reduce current carrying ability far more dramatically than does skin effect, and at much lower frequencies.

The proximity effect therefore has the potential to cause localised 'hot spot' thermal problems, that degrade the insulation and cause eventual failure. It is especially problematical when the transformer current is highly distorted, and this is invariably the case when a transformer is used with a bridge rectifier and filter capacitors.

Despite the above, it's almost certain that there will be identifiable minor localised heating, but as noted it is unlikely to cause reduced life of any transformer used for audio or other applications that are of interest to hobbyists or typical commercial products. Given the legendary reliability of transformers - most of which will outlast the product - the proximity effect never seems to have caused premature failure. Most transformer failures are the result of much more mundane abuse, such as consistent long-term overload.

However, the proximity effect does cause failures in large distribution transformers, and is also said to lead to motor failures. These failures are almost always attributable to a highly distorted mains current waveform, and may be localised to a single industrial installation. I suggest that the reader not stress about it - you didn't even know about it until now.

Copper loss is responsible for a transformer's regulation - the ratio of voltage at no load versus full load. Regulation is almost always specified into a resistive load, which considering the way nearly everyone uses transformers, is virtually useless. It is rare that any transformer is operated into a purely resistive load - the vast majority will be used with a rectifier and filter capacitors, and the manufacturer's figure is worthless. Actually, it is worse than worthless, as it misleads the uninitiated to expect more voltage than they will obtain under load, and causes people grief as they try to work out why their amplifier (for example) gives less power than expected.

Naturally, there are some to whom any measurement is sacrilege, so none of this applies to them

The output voltage is (nearly) always specified at full load into a resistance. So a 50V, 5A transformer will give an output of 50V at a sinewave output current of 5A. If the regulation of this transformer were 4%, what is the no-load voltage?

The answer is 52V. Regulation is determined quite simply from the formula ...

Reg% = ( VN - VL) / VL × 100 / 1

Where VN is no-load volts, and VL is loaded volts.

As determined earlier, this assumes a sinusoidal output current, and this just does not happen with a rectifier / filter load. It may be found that this same transformer has an apparent regulation of 8 to 10% when supplying such a load. See Linear Power Supply Design for more information on this topic (there is little point in doing the article twice :-)

The regulation with rectifier loads is a complex topic, but you will need to know the ramifications before you start construction of your latest masterpiece, rather than find out later that all your work has resulted in much lower output power than you expected. Not that you can change it for any given transformer, but at least you will know what to expect.

To gain a full understanding of regulation requires a lot more information than I can provide in a simple web page, but a crucial factor is getting the balance of winding resistances right. If you are making your own transformer you'll do this as a matter of course, but will a manufacturer (in the 'far-East') go to the trouble? I'm not about to debate that point. If we determine from the specification that regulation is (say) 6% for a reasonable sized transformer (around 500VA), we can work out everything we need to know.

Knowing the regulation and voltage, we can calculate the effective winding resistance. A 50V transformer with 6% regulation will give us 53V at no load, and 500VA at 50V means 10A - all very straightforward. We lose 3V at full current, so the total effective winding resistance must be ...

Rw = V / I = 3 / 10 = 0.3 Ohms

Half of this resistance is in the secondary, and the other half is reflected from the primary, based on the impedance ratio. As you will recall, this is the square of the voltage ratio. If we assume a primary voltage of 230V, output voltage of 50V at 10A, we already know that the unloaded output voltage is 53V. The turns and impedance ratios (TR and ZR respectively) are therefore ...

TR = VIN / VOUT = 230 / 53 = 4.34:1

ZR = TR² = 4.34² = 18.83:1

Knowing this, we can determine the optimum winding resistance for each winding. Since half of the resistance is that reflected from the primary (Rp), the secondary resistance (Rs) is 0.15 ohms, being half of the total. Primary resistance must be ...

Rp = Rs × ZR = 0.15 × 18.83 = 2.82 Ohms

Based on all that, it is now possible for the designer to determine the appropriate wire gauge for the number of turns needed for the core size. The ideal case is that the resistive (copper) losses should be as close as possible to identical for both windings, and this is why we worked out the resistance. At full load, dissipation (copper loss) is 15W for each winding (almost exactly) at full load. Total dissipation is therefore 30W, and the transformer efficiency is 94.3% ...

Eff (%) = POut / Ptot × 100 / 1 = 500 / 530 × 100 / 1 = 94.34%

It may not be immediately obvious, but there is a very good reason for keeping the primary and secondary copper losses equal. Any core only has a limited space for the windings, and this space must be used as efficiently as possible. It follows that if one winding is thicker than necessary, the other has to be thinner so it will fit in the space allowed. This invariably leads to total losses that are greater than would be the case if the resistance is optimised as described. In the case of toroidal transformers, there is good reason to keep primary losses lower than secondary losses, because the primary winding is trapped inside the secondary winding and heat can only escape through the outer layers. The toroidal core doesn't act as a heatsink either, because it's inside all the windings.

| VA | Reg % | RpΩ - 230V | RpΩ - 120V | Diameter | Height | Mass (kg) |

| 15 | 18 | 195 - 228 | 53 - 62 | 60 | 31 | 0.30 |

| 30 | 16 | 89 - 105 | 24 - 28 | 70 | 32 | 0.46 |

| 50 | 14 | 48 - 57 | 13 - 15 | 80 | 33 | 0.65 |

| 80 | 13 | 29 - 34 | 7.8 - 9.2 | 93 | 38 | 0.90 |

| 120 | 10 | 15 - 18 | 4.3 - 5.0 | 98 | 46 | 1.20 |

| 160 | 9 | 10 - 13 | 2.9 - 3.4 | 105 | 42 | 1.50 |

| 225 | 8 | 6.9 - 8.1 | 1.9 - 2.2 | 112 | 47 | 1.90 |

| 300 | 7 | 4.6 - 5.4 | 1.3 - 1.5 | 115 | 58 | 2.25 |

| 500 | 6 | 2.4 - 2.8 | 0.65 - 0.77 | 136 | 60 | 3.50 |

| 625 | 5 | 1.6 - 1.9 | 0.44 - 0.52 | 142 | 68 | 4.30 |

| 800 | 5 | 1.3 - 1.5 | 0.35 - 0.41 | 162 | 60 | 5.10 |

| 1000 | 5 | 1.0 - 1.2 | 0.28 - 0.33 | 165 | 70 | 6.50 |

The primary resistance for all of the examples in the above table was calculated using the method shown - this figure is rarely given by manufacturers. Resistance is shown for both 230V and 120V primary windings. Knowing the basics at this level is often very handy - you can determine the approximate VA rating of a transformer just by knowing its weight and primary resistance. The secondary resistance can be calculated from the primary resistance and the turns ratio. The result obtained by using nominal turns ratio (based on the stated primary and secondary voltages) is accurate enough for most purposes. As shown by the range provided, the primary winding resistance could be up to 15% lower than calculated to reduce the current density in the primary. (See Reusing Transformers for another table covering a wider range of VA ratings.)

Taking the 500VA example again, and assuming a 230V primary and a dual 50V secondary winding (100V total), the total secondary resistance is ...

TR = Vp / Vs = 230 / 100 = 2.3

ZR = TR² = 5.29

If the primary resistance is 2.8 ohms (from the table), then the secondary resistance must be approximately ...

Rs = Rp / ZR = 2.8 / 5.29 = 0.53 Ohm

The resistance of each half of the secondary winding is naturally half of the total.

Note: Because of the common practice of using different current densities for the inner (primary) and outer (secondary) wire, this will skew the figures shown here slightly. The figures determined above are based on a theoretical 'ideal' case, but this will rarely translate into reality due to the inevitable 'fudge factors' that are applied to real world parts. Basic tests I've run indicate that the above figures are more than satisfactory for a quick check of the expected resistances. As a very basic rule, expect the primary resistance to be a little less than calculated, and the secondary resistance will be a little higher.

Since the transformer is not an ideal device, it has unwanted properties apart from the losses described so far. The other losses are relatively insignificant for a power transformer, but become difficult to manage for transformers intended for wide bandwidth, such as microphone transformers and valve output transformers.

The standard equivalent circuit does not include frequency dependent disruptions such as skin or proximity effect. Nor does it include any means to simulate the non-linear magnetising current in a power transformer. As such, it is limited to general simulations of small signal transformers, valve amplifier output transformers (but only at low levels and/or higher frequencies) and similar. While it can still be used with a power transformer, the results are generally not at all useful. Power transformers generally require measurements to confirm the overall performance, and we are only interested in low frequencies - 50Hz and 60Hz.

Figure 11.5 - Transformer Simplified Equivalent Circuit

The equivalent circuit shown in Figure 11.5 is greatly simplified, but serves to illustrate the points. Since the windings are usually layered, there must be capacitance (C1 and C2) between each layer and indeed, each turn. This causes phase shifts at high frequencies, and at some frequency, the transformer will be 'self resonant'. This is not a problem with power transformers, but does cause grief when a wide bandwidth audio transformer is needed.

In addition, there is some amount of the magnetic field that fails to remain in the core itself. This creates a 'leakage' inductance (LL) that is effectively in series with the transformer. Although small, it tends to affect the high frequencies in particular, and is especially troublesome for audio output transformers. This is typically measured with an inductance meter, with the output winding short circuited. Any inductance that appears is the direct result of leakage flux.

Lp is the primary inductance, and as you can see, there is a resistor in parallel (Rp). This represents the actual impedance (at no load) presented to the input voltage source, and simulates the iron losses. The series resistance (Rw) is simply the winding resistance, and is representative of the copper losses as described above.

Cp-s is the inter-winding capacitance, and for power transformers can be a major contributor to noise at the output. This is especially irksome when the transformer is supplying a hi-if system, and mains borne noise gets through and makes horrid clicks, electronic 'farts', electric motor whine, and various other undesirable noises in the music. Toroidal transformers are very much worse than conventional (E-I) transformers in this respect, because of the large area of each winding. An electrostatic shield will all but eliminate such noises, but these are expensive and uncommon with toroids (pity).

This problem always exists when the capacitance between primary and secondary is high - electrical noise on the primary is capacitively coupled from the primary to the secondary. As noted above, this can lead to mains noise getting through the entire power supply and into the amplifier in extreme cases. The electrostatic shield is very effective, and this is connected to earth. Note that the shield cannot be joined in a complete circle around the winding, as this would create a shorted turn that would draw a tremendous current and burn out the transformer.

There is a technique that is used for valve output transformers, shown in Figure 11.6 - you will not find this method used in power transformers, as it is completely unnecessary and increases the primary-secondary capacitance dramatically.

Figure 11.6 - Interleaved Winding for Extended HF Response

The trick to winding transformers to minimise the winding leakage inductance and self capacitance is called 'interleaving', but this results in much greater inter-winding capacitance. The most common way an interleaved winding is done is to use a multi-segmented winding, as shown in the sectional drawing of Figure 11.6. This type of winding is (or was) quite common for high quality valve output transformers, and the extension of frequency on the top end of the audio spectrum is very noticeable.

The capacitance between the primary and secondary can become troublesome with this technique, and although possible, an electrostatic shield (actually, a number of electrostatic shields may be needed) adds considerably to the cost, but creates a minimal overall benefit. This winding method is not used (or needed) with low frequency power transformers, and would lead to greatly reduced electrical safety because of the difficulty of insulating each section from the next. The same problem also exists with an output transformer, but is easier to control because one side of the secondary is earthed and the internal DC is already isolated from the mains.

All the losses add together to increase the temperature of a transformer. Insulation materials (wire enamel, inter-layer insulation, formers and/or bobbins, tape overwinds, etc.) all have limits to the maximum safe temperature. It should come as no surprise that the high temperature materials are considerably more expensive than lower temperature grades, and as always there is a trade-off (compromise) between minimising losses for cool running or reducing the size and weight at the expense of greater losses and higher temperature operation.

There are several internationally recognised temperature grades, as well as one that is recognised by the authorities, but the class designation is not universally accepted. Temperature is specified as either an absolute maximum figure, temperature rise, or both. The standard classes are ...

| Class | Max. Temp. | Temp Rise |

| A | 105 °C | 60 °C |

| E | 120 °C | 75 °C |

| B | 130 °C | 80 °C |

| F | 155 °C | 100 °C |

| H | 180 - 200 °C | 125 °C |

| C (not global *) | 220 °C | 160 °C |

* Class-C is not a globally recognised class, but 220°C is accepted under several different world standards.

It's inevitable that transformers in use will get hot, and it is up to the equipment designer to ensure that the insulation class is adequate for reliable operation over the life of the equipment. Unless stated otherwise, you can expect that nearly all commercial off-the-shelf transformers intended for DIY applications will be Class-A (105°C maximum temperature). Higher temperatures are not recommended anyway, for the simple reason that having a transformer at (say) 100°C will transfer its heat to transistors, electrolytic capacitors and all other components in the chassis. For this reason alone, specifying a larger than necessary transformer not only reduces temperatures, but improves regulation as well.

All power transformers are rated for either a specific input voltage and frequency, or for a limited range. Often, dual primaries are used that allow the user to connect the windings in series or parallel as shown in Figure 8.1, but on the primary instead of the secondary. The most common configuration is to have two windings, each rated for 120V. For 120V mains, these are wired in parallel, and wired in series for 230/240V.

Sometimes, the primary windings will be rated for 115V each. This has long been a problem in the US, with no-one quite certain for many years whether the voltage is 110, 115, 117 or 120. According to US standards, the nominal mains voltage in the US and Canada is 120V, but like everywhere else it varies from one place to another and with time of day. All power transformers must be wound to take this inevitable variation into account. (Note that the US also uses a 'two-phase' system, providing 240V at 60Hz - this is not the same as using two phases of a 3-phase connection, where the voltage is 208V at 60Hz.)

While just two windings are common now, it used to be the case that transformers had multiple taps on the primary winding, or used several windings that could be connected in often mysterious ways using a complex switching system. These still exist, but mainly as salvage items. The range of voltages offered was intended to cover anywhere in the world, but also could lead to a wrong assumption and blown fuses (or a burnt out transformer).

Ultimately though, the claimed voltage of a transformer is the easiest to verify - the nameplate rating is always correct. I have never seen a transformer that claimed to be 230V (or some other voltage) that didn't work properly at that voltage. Of more concern is the frequency rating. While usually stated, it is sometimes confusing to the uninitiated.

A transformer rated for 50Hz can be used anywhere in the world - it will work perfectly at 60Hz. However, the converse is not true. A transformer designed specifically for 60Hz will overheat at 50Hz, even if the voltage is correct! This is not well understood, and leads to an enormous amount of traffic on Usenet and in forum pages everywhere. The answer is quite simple - 60Hz is 20% greater than 50Hz, so the core and turns per volt can both be reduced by up to 20% compared to a 50Hz transformer of the same rating.

Therefore, a transformer that was designed for 60Hz at 220/230V (The Philippines, South Korea and a few others use this combination [Ref]) has a smaller core and fewer turns than an otherwise identically rated 50Hz transformer. As a result, it will most likely fail with 220V at 50Hz. Operating a 60Hz power transformer at 50Hz is exactly the same as operating the transformer at its rated frequency, but with a 20% voltage increase. If you absolutely must run a 60Hz transformer at 50Hz, you must reduce the mains voltage from the rated value (say 230V) by 20% (184V). This is a large drop, and exceeds the normal mains variation allowances that are provided for in properly designed circuits.

Failure to reduce the voltage will cause the transformer to be heavily into saturation, and it may easily consume half its rated VA (or more) at idle, due to excessive magnetising current caused by core saturation. Needless to say, the secondary voltage will also be reduced by the same percentage. For evidence of the current increase due to core saturation, see the next section (specifically Figure 12.1.1).

Operating a 60Hz transformer at 50Hz is effectively the same as a 20% increase in mains voltage, but note that this does not mean that the secondary voltage is increased. For a 230V transformer that's the same as running at 60Hz, but at a supply voltage of 276V. The core will be seriously saturated, and the magnetising current will be increased dramatically.

Should the power transformer be for a valve amplifier, care is needed, because the valve heaters will be operating from a lower than normal voltage (6.3V will only be 5V) and may not reach the proper operating temperature. Output power is also reduced, and a 20% reduction of voltage will reduce the maximum power to fall from (say) 100W to 64W, a drop of just under 2dB. It also means that all unregulated preamp supplies will be 20% lower. With regulated supplies, the drop might be enough to cause the regulator ICs to allow rectified mains buzz through to the signal circuits.

For information about how you can reduce the supply voltage (in this case by 46V), see the article Bucking Transformers. While the methods described certainly do work, the other compromises you have to make will almost certainly mean that the transformer will have to be replaced to maintain original performance.

Should you have a transformer rated for 240V at 50Hz and wish to use it at a lower voltage and/or 60Hz, then there is no problem. If used at 120V 60Hz, the transformer will operate with an exceptionally low magnetising current, but the secondary voltages will obviously be halved. While the maximum current rating remains the same, regulation will be worse than a transformer wound for 120V mains because the winding resistance is higher.

In short, you can operate a ...

Likewise, you cannot operate a ...

Note that I have simply assumed 20% in both directions (50Hz to 60Hz and 60Hz to 50Hz), although it is clear that a reduction from 60Hz to 50Hz is actually 17%. Feel free to think of the extra 3% as a safety margin.

I measured the characteristics of a small selection of transformers to give some comparative data. I excluded regulation from this, as it is difficult to make a suitable variable load, and loads tend to get rather hot even with short usage. Most manufacturers will provide this information in their specifications, but be warned that this refers to a resistive load, and regulation will be much worse when supplying a conventional rectifier and filter capacitor (see above, and the Power Supply Design article for more details). It is also worth noting that an inductance meter is often of little use with large iron cored transformers, unless it operates with a sinusoidal waveform at (or near) the design frequency of the transformer. The inductances shown are calculated, since the measured values with my meter were a long way off.

Bear in mind that the inductance value shown is nominal, based on the magnetising current (which is actually distorted for most transformers), and is much lower than the real value. It is included only as a guide - the actual value will be much higher, but only with a lower primary voltage that ensures that the core is nowhere near saturation. Manufacturers don't provide this figure, because it's meaningless in the real world.

| Type | Rating | Inductance | Resistance | Turns/Volt | Magnetising | Core Loss | Reactance | Mass (kg) |

| Toroidal | 500VA | 34.7 H | 2R4 | 2 | 22mA | 5.28W | 10.91k ohms | 5.0 |

| Toroidal | 300VA | 63 H | 5R1 | 3 | 12mA | 2.88W | 20k ohms | 2.7 |

| E-I | 350VA | 4.36 H | 6R6 | 2 | 175mA | 42W | 1.37k ohms | 3.2 |

The toroidal transformers are clear winners in terms of core loss in particular, but it must be said that the E-I transformer tested is not really representative of the majority. This is one of a few left that I had specially made to my design, and they were deliberately designed to push the saturation limits of the core. These transformers run quite warm at no load, but give better regulation than a more conservative design - the vast majority of such transformers. They were actually designed to run just above the 'knee' of the B-H curve for the laminations used, and although somewhat risky, none has failed (to my knowledge) since they were made about 20 years ago. I used a pair of them in my hi-if system, and they were in daily use for 10 years (the 4-channel amp has subsequently been changed for a slightly lower power version). I originally got the idea of designing transformers like this long ago, when I used to make my own transformers for guitar and bass amps. I ran some tests at the time, and found that by pushing the core a little harder, I could make a transformer that had better regulation than anything I could buy from any of the existing manufacturers. I never had a transformer failure.

It is also worth noting that the mass is lower than for a more 'traditional' transformer design - a conventional design of the same power rating would be expected to weigh in at about 5kg.

Figure 12.1 - Current vs. Voltage for the E-I Transformer

To take my measurements to the logical limit, I measured the magnetising current of my sample E-I transformer. Look closely at the graph in Figure 12.1, and you will see a typical BH curve (as shown in Figure 11.2 but with the axes reversed). As you can see, at 240V input, the transformer is operating at the knee of the curve, and is well on the way to saturation. There was no point doing this for the toroidals, as they are operated well below saturation level and I would be unable to (conveniently) measure them.

Toroids usually have a more pronounced knee, and a correspondingly steeper rise in current once the saturation limit has been reached. This is primarily because of the fully enclosed magnetic path, which has no air gaps at all. E-I laminated transformers have a small but significant gap where the 'E' and 'I' laminations meet. This is unavoidable in any practical transformer, but has little effect on performance in real life.

For these measurements, I used a 300VA toroidal transformer, but not the same one as was used for the data in Table 12.1. There seems to be very little on the Net that discusses or shows actual (as opposed to theoretical or imagined) magnetising current. The true value of this varies more or less linearly up to the point where the core approaches saturation, but it is very common that power transformers are designed so that they are already into the non-linear part of the BH curve for normal operation.

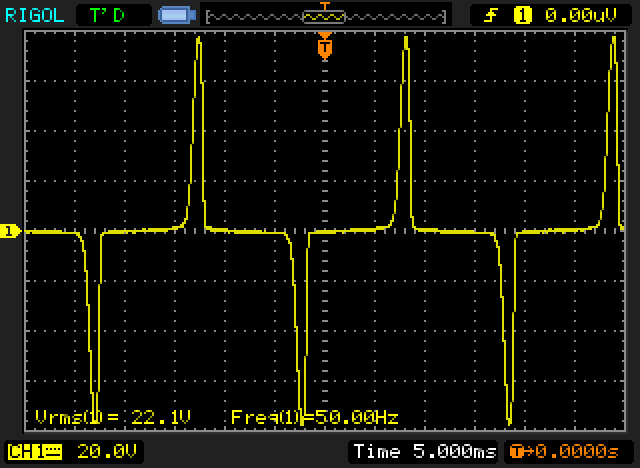

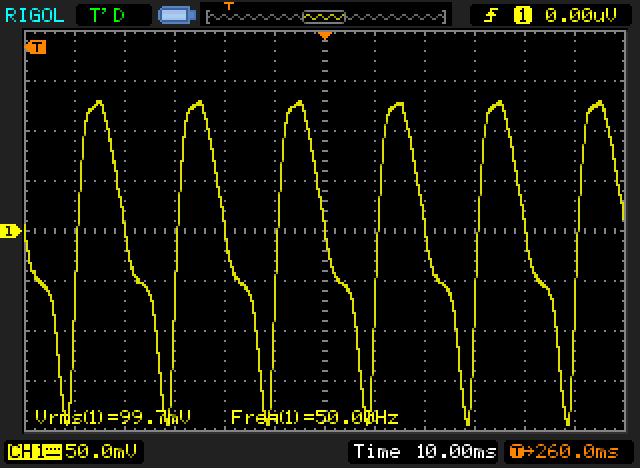

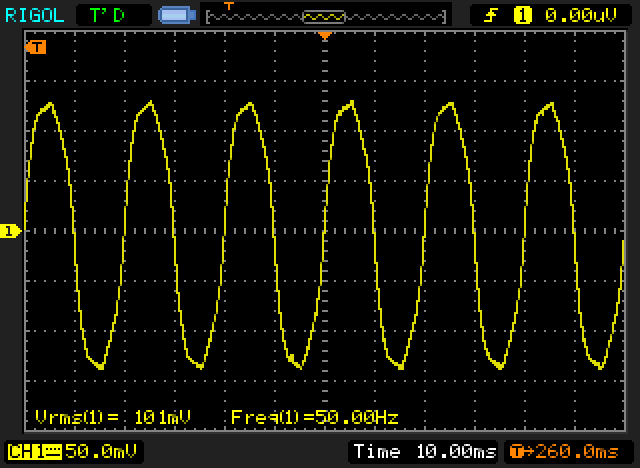

While this region is usually well below true saturation, the current waveform is already quite distorted, because the mains voltage peaks cause the flux to rise to its maximum value, so additional current is drawn at the peak of the AC waveform, displaced by 90°. This is shown below, for a 240V, 300VA toroidal transformer, operated at four different voltages ... the first (A) is well below saturation at 120V, the second (B) at nominal input voltage (240V), the third (C) at a voltage that is somewhat greater (280V) and the last (D) at an excessive mains voltage (290V). The transformer was designed for nominal 240V operation.

Figure 12.1.1 - Magnetising Current Vs. Input Voltage

The magnetising current is a nice friendly 7.3mA at 120V input, and at 240V is showing signs of saturation, but the current is still only 42mA. When the voltage is increased further, saturation is clearly well advanced - at 280V the transformer draws 443mA, but just a small further increase to 290V causes the current to soar to 1.6A - exceeding the transformer's continuous VA rating with no load. If you look carefully at Figure 12.1.1.A, you will notice that the waveform is slightly asymmetrical. This indicates that there is probably some remanent flux in the core from the last time the transformer was used.

The volt-amps dissipated in the transformer primary winding is determined by VA = V * I, so at 240V the transformer draws only 10VA, climbing to 124VA at 280V and a rather spectacular 464VA at 290V. Assuming the typical primary resistance of 4.7 ohms for a 300VA transformer, the power loss in the primary at each voltage (in turn) is 250uW, 8.2mW, 0.9W and 12W at 290V.

As you can see from the graphs (B, C & D), the current is highly non-linear, so cannot be corrected for power factor. While this is a common error made all over the Internet, there is no way that a non-linear waveform can be corrected for power factor by adding a capacitor. At best, you might be able to add a capacitor that creates a filter which reduces the peak current and improves the PF very marginally, but it will only be effective at one location and/or voltage. Any such filter will rely on the mains impedance, and is guaranteed overall to make matters worse, never better.

Adding a power factor correction capacitor will only work if the cap is sized to draw a leading current of around 14mA (for this transformer). This is the only linear part of the magnetising current, being double the 'nice sinewave' current drawn at 120V. True magnetising current is a linear function of voltage, based on the reactance of the winding. This would imply a capacitor of around about 180nF - unlikely to be useful (ok, it's completely pointless  ).

).

The actual magnetising current drawn (including that caused by core saturation) is a non-linear function, and is extremely difficult to simulate unless one has access to a simulator that handles iron cores properly. While such a thing may exist for transformer designers, I've not seen any simulation that comes even close to reality as shown above. Note that these are actual captured waveforms from a real transformer connected to a high power Variac. As you can see, the saturation current waveform remains much the same once the core is thoroughly saturated, but the magnitude increases exponentially with voltage increase.

With 290V applied, the peak current is about 5A (2A per division on the screen). You will see that the vertical resolution has been changed for each capture, and the current monitor also has variable gain to maximise resolution. That is why the measured current may seem to be different from the oscilloscope display, but the reading in volts has been converted into mA.

When the transformer is loaded with a resistance, the voltage and current waveforms are in phase. Contrary to popular belief, a linearly loaded transformer (i.e. resistive load) does not produce a lagging power factor, except for the small magnetising current's contribution. As we can see from the above, this is negligible. I tested the same transformer with a 16 ohm load across one of the nominal 20V secondaries, and the input voltage and current waveform were perfectly in phase at any input - from less than 5V RMS up to the full rated primary voltage.

When powered on, many transformers draw a very high initial current. This phenomenon may not be noticeable with smaller transformers, but as the component gets larger (above ~300VA) it tends to occur most of the time. You may see lights dim momentarily when a large transformer is switched on, and now you know why. The core saturates when power is applied, so very high current is drawn until normal operation is established (after around 20 complete mains cycles). The magnitude of the inrush current is a combination of several factors ...

The longer a transformer is left un powered, the lower the remanent flux, and the less likelihood there is of an excessively high inrush current. This is a nice theory, but in reality it makes no practical difference. Of far more importance is the point on the mains waveform where the power is actually applied. If the mains is applied when at its peak value, inrush current is at its lowest. Conversely, if the mains is applied at the zero crossing point, inrush current will be maximum - this is exactly the reverse of what you might expect, and is shown below. The inrush current lasts for several cycles, and is made much worse with a rectifier and filter capacitor on the output. The capacitor is a short circuit when discharged, and large capacitors will take longer to charge. The inrush current due to capacitors charging is not asymmetrical - that privilege is reserved for core saturation at power-on.

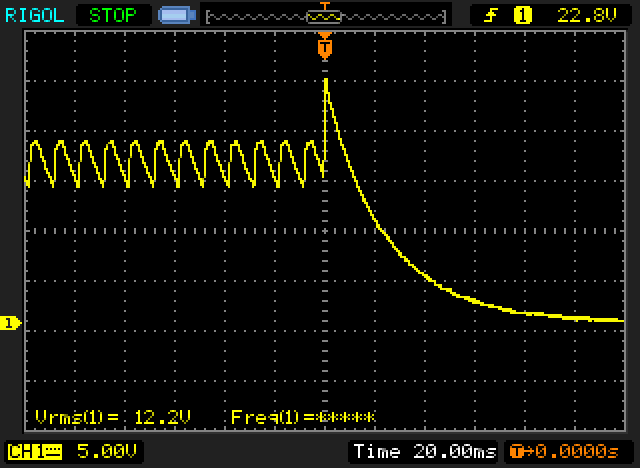

Figure 12.2 - Transformer Inrush Current

The above is an oscilloscope capture of the current in a 200 VA E-Core transformer, when power is applied at the zero crossing of the mains waveform. This is the worst case, and can result in an initial current spike that is limited only by the winding and mains wiring resistance. For a large toroidal, peak currents can easily exceed 150A. If the mains is applied at the peak of the AC waveform (325V in 230V AC countries, 170V where the mains is 120V), the peak inrush current for the same transformer is typically reduced to less than 1/4 of the worst case value ... 4.4A (both can be measured with good repeatability for the transformer tested).

As you can see, the inrush current is one polarity (it could be positive or negative), so superimposes a transient 'DC' event onto the mains. Other transformers that are already powered may also saturate (and often growl) during the inrush period. This is often known as 'sympathetic interaction'. To minimise the effects of inrush current and flow-on effects with other equipment, any toroidal transformer over 300VA should use a soft-start circuit such as that described in Project 39.

The term 'voltage surge' is often bandied about, but very few people using the term have the slightest idea what it might mean or how it may be created. It's become something of a 'catch-all' phrase that can be used to convince the customer that their equipment probably failed due to said 'voltage surge'. In reality, they can (and do) happen if there's a major fault in the distribution system (a high voltage feed coming into contact with the 'normal' 230V or 120V distribution supply for example, or a nearby lightning strike). However, mostly it's just a way to convince the customer that it's their fault and to forget about any warranty. (Of course, this often also leads to the sale of an overpriced 'power conditioner' that may or may not save the gear from future 'voltage surges').

However, you can get a voltage surge (I don't like the term because it's too non-specific) simply by turning a transformer off if the switch is a bit iffy, and fails to break the supply cleanly. An electric arc will always be developed as the switch opens, but if the switch is old and worn, you can easily get an arc that's bigger and nastier that normal. Should this happen, the transformer will cheerfully pass whatever happens at its primary winding across to the secondary. Mostly, it's not an issue, because there's either a significant load, or in the case of power amplifiers, a robust filter bank after the rectifier. This will absorb any 'excess' voltage without raising the DC voltage significantly. The use of an electrolytic cap with a high ripple voltage is a very bad idea, and (apart from the surge) the cap will fail due to excess ripple current, but this is the test circuit used ...

Figure 12.3 - Transformer 'Surge' Test Circuit

The following trace was taken with the deliberately undersized capacitor after the rectifier - in this case, just 10µF, with a 2.2k resistor in parallel. The test transformer was a 12V 1A unit, and provides a peak voltage across the cap of 18V. As you can see, the peak voltage can easily reach 24V (peak). Using a transformer with a higher output will obviously generate a larger peak. Normally, you would never use such a small capacitor, and even for a low power supply you'd expect nothing less than 220µF, and usually a great deal more. However, it was (apparently) done in a very old National Semiconductor application note (no longer available), and resulted in the regulator IC failing. It was (again, apparently) determined that there was some mysterious interaction of transformer magnetising current and residual core magnetism, but this is simply not the case at all.

Figure 12.4 - Transformer Voltage 'Surge'

When a transformer is fed from an unstable (negative) impedance such as an arc, it can (and probably will) react at its own self-resonant frequency, and can quite easily generate a voltage that's far greater than the nominal mains, and at a much higher frequency determined by the transformer itself. It's difficult (but not impossible) to draw a useful arc with a small transformer, but it may be quite easy with a larger one - of course, much depends on the transformer itself. Remember that a transformer couples anything that happens on its primary to the secondary, and vice versa. The limit to this is set by the leakage inductance, but the effect is seen easily in the above trace, and there can be no doubt that using an undersized capacitor can cause 'unexpected consequences'. Due to transformer action, any voltage (surge or otherwise) you see at the secondary must also be present on the primary, as determined by the transformation ratio. This was also measured and verified, but isn't shown here.

Note that this effect is not reliable - it took several attempts to capture the peak shown, so it's easy to (mistakenly) assume that the circuit will be fine. All it needs is the right (or wrong) combination of switch-off time with respect to the transformer's current, and a switch that allows an arc as it opens. The transformer must also be subjected to a very light or no-load at the time. Most circuits don't present this condition, so problems are very rare.

Using an additional 33µF cap in parallel with 10µF reduced the maximum peak I saw to about 23V, but with no cap at all, the voltage reached 60V for 32µs across the 2k2 resistor. That's an instantaneous power of 1.6 watts in the resistor. I only managed that once, but had I kept trying it's inevitable that it would have happened again. The worst-case voltage spike you get depends on the transformer itself. Some will produce a large impulse, while others may generate nothing more than some noise.

By its very nature, an arc is an unstable condition and is impossible to predict. However, it's quite obvious that a voltage spike can and does happen. This isn't something that will normally cause a problem with sensible circuits, but it certainly needs to be considered if you are doing something unusual. You will need to provide some additional circuitry to ensure that the peak is absorbed without an excessive 'voltage surge', especially if the output supplies anything sensitive (IC, MOSFET gate, etc.). A TVS diode (transient voltage suppressor) or a pair of back-to-back zener diodes can be used to clamp the worst case voltage to perhaps 24V or so if necessary for your circuit.

The inductance of a mains transformer is not normally part of its specifications. This changes if it's designed for a switchmode power supply or for audio coupling. For normal mains frequency applications, the figure we are interested in is the magnetising current. As shown above in Figure 12.1.1, the magnetising current is non-linear, so if you do need to know the inductance you must take the measurement at a voltage that's well below the nominal primary voltage. If you have a way to monitor the current waveform, you can verify that there is no evidence of saturation at the test voltage (see Project 139 or Project 139A for suitable current monitors).

Once you know the voltage and current you can calculate the impedance, and from that you can work out the inductance ...

XL = V / I (where V is applied RMS voltage and I is RMS current) L = XL / ( 2π × f ) (where f is the applied frequency)

For example, the transformer I used to produce the oscilloscope captures in Figure 12.1.1 draws 7.31mA with a mains voltage of 120V at 50Hz.

XL = 120 / 7.31 = 16.41 kΩ

L = 16.41 k / ( 6.283 × 50 ) = 52.25 Henrys

This is an interesting 'figure of merit', but it's not actually useful for anything. Of course, if you have a need for a 52H inductor you can use the primary winding to get it, but remember that it will start to saturate at not much more than 10mA. If you tried to use it for audio, the distortion will be quite high at even lower currents, especially as the frequency is reduced below 50Hz. In addition, the inductance will almost certainly be non-linear. The test transformer's inductance fell to 42H with a voltage of 35.2V and a current of 2.64mA.

While generally not at all useful, it's important to understand that the inductance ratio of a transformer is based on the square of the turns ratio. A transformer with a primary of 50H and a 10:1 turns ratio has a secondary inductance of 500mH. This might be handy to know if you like to play with mains transformers in reverse (to obtain a step-up), but in general it's not helpful, and nor is it useful for much. It is something that you might need to know sometime though, and it reflects the impedance ratio - also based on the square of the turns ratio.

As noted above, inductance is part of the specification for switchmode power supply and audio transformers. That's because they are operated in a somewhat different way from mains or other transformers. One area of commonality is that saturation must be avoided, and like mains transformers saturation is worse with no load. For the same power output, a switchmode transformer will be a great deal smaller than a conventional transformer operating at 50 or 60Hz. Typical operating frequencies range from a few kHz up to 100kHz or more. As a rough guide, the necessary size of a transformer will halve for each doubling of frequency (and vice versa of course), but there are many other influences that must also be considered. A complete discussion of this is way outside the intent of this article.

Leakage inductance is caused by magnetic flux that fails to include both primary and secondary windings. The things that influence it include the core material, core geometry, winding topology and air gaps (whether intended or otherwise). It's shown as a separate small inductance in series with the winding resistance (see Figure 11.5) and is a parasitic element. For most transformers it's an undesirable characteristic, but in a few switchmode topologies it's actually used as part of the circuit. Details of this are (not surprisingly) not part of this article.

Toroidal cores generally show the least leakage inductance of mains (i.e. 50/60Hz) transformers because the windings encircle the core, and the core itself has no air gaps. A low value of leakage inductance is not essential for mains frequency transformers, but keeping leakage low helps to prevent stray magnetic fields from generating a voltage and current in the chassis and/or nearby wiring. I measured both primary and secondary leakage inductance with a number of transformers I had to hand, and got the following results.

| # | Secondary | VA | Primary | Secondary | Construction |

| 1 | 12.6 | 2 | 762 mH | 2.35 mH | E-I |

| 2 | 15-0-15 | 80 | 6.4 mH | 130 µH | Toroidal |

| 3 | 25-0-25 | 160 | 1.8 mH | 180 µH | Toroidal |

| 4 | 28-0-28 | 200 | 8 mH | 570 µH | E-I |

| 5 | 30-0-30 | 300 | 1.63 mH | 115 µH | Toroidal |

In theory (a wonderful thing  ) the leakage inductance of the secondary can be calculated if you know the value for the primary. It's directly proportional to the square of the turns ratio, so for #2 above, the turns ratio is 230/30 (two 15V windings), or 7.7:1 based on the rated voltage (as opposed to the actual turns ratio). With a primary leakage inductance of 6.4mH, the calculated secondary leakage is 108µH. In reality, the turns ratio will be closer to 7:1 to allow for the transformer's regulation (an unloaded voltage of about 33V, which is close to what we'd expect).

) the leakage inductance of the secondary can be calculated if you know the value for the primary. It's directly proportional to the square of the turns ratio, so for #2 above, the turns ratio is 230/30 (two 15V windings), or 7.7:1 based on the rated voltage (as opposed to the actual turns ratio). With a primary leakage inductance of 6.4mH, the calculated secondary leakage is 108µH. In reality, the turns ratio will be closer to 7:1 to allow for the transformer's regulation (an unloaded voltage of about 33V, which is close to what we'd expect).

The formula now gives the exact figure calculated. The question now is "Just how does one measure leakage inductance anyway?" It's not difficult if you have an inductance meter, because you simply measure the primary inductance with the secondary short-circuited. The 'ideal' part of the transformer is now out of the equation, and what you measure is the leakage inductance. Small transformers can be problematic, because the winding resistance may be so high that it confuses the meter, giving an unrealistically high reading.

The other method is to use a sinewave audio oscillator and an oscilloscope or AC millivoltmeter. Measure the primary resistance (you need this as a reference), and use a resistor from the oscillator that's at least ten times the measured primary resistance. Short-circuit the secondary winding(s), then set the oscillator to a (very) low frequency (~10Hz is suggested) and measure the voltage across the transformer. Next, increase the frequency until the voltage across the transformer has risen by 3dB (1.414 times the initial voltage). Note the frequency.

L leakage = RP / ( 2π × f ) (Where RP is primary resistance and f is frequency)

The useful part of this method is that the winding resistance is immaterial - you will get the right answer regardless of resistance because the resistance is included in the formula. The audio voltmeter you use is important - most digital meters have a very limited high frequency response, and cannot be relied upon to give an accurate reading above 1kHz or so. Unless you are 100% certain that your meter extends to the frequency you need, the reading can't be trusted.

To show how this works, I measured transformer #1 with an inductance meter, which showed a primary leakage inductance of 1.3H. It's really only 762mH when measured using the method described. The secondary leakage inductance was similarly inflated, showing 6.12mH instead of 2.35mH. The primary resistance is 1,077Ω, and the +3dB frequency was 225Hz (now you can calculate it using the formula shown to see the proper result). Remember to remove the short from the secondary before you connect the transformer to the mains!

It's apparent from this that small transformers are worse than larger ones, and E-I laminations are worse than toroidal cores. This is to be expected once you know what you are looking for. However, it's important to understand that this doesn't affect the operation of mains frequency transformers, and while it's common to see 'perturbations' resulting from the interaction of leakage inductance and diode turn-off commutation, this doesn't affect the efficiency or the DC output (see Power Supply Snubbers for a detailed analysis). In some cases, the turn-off impulse might cause some RF interference (conducted or radiated emissions).

However - and this is important - leakage inductance is a critical figure for transformers used in switchmode power supplies. Because these supplies use a high frequency rectangular waveform, leakage inductance causes ringing which can create over-voltages capable of damaging the switching MOSFET(s) or even the transformer's insulation. A snubber network (a series resistor and capacitor - essentially a Zobel network) is almost universally employed to damp the ringing waveform. Minimising leakage inductance means that the snubber isn't as critical and dissipates less power. This becomes more important when high efficiency is expected, because the resistive component dissipates power and generates heat. This can become significant if the transformer isn't designed for low leakage inductance.

There is a huge array of different core shapes, and each has its own advantages and disadvantages. The two most common for commercial and DIY audio equipment are the standard E-I core and the toroidal core, but there are many others. Occasionally you will see C-cores, double-C-cores and R-cores, but these are not as common as the two most popular types.

Ferrites in particular are moulded and fired to get the shape and magnetic properties desired. Because the initial shape is moulded, it's comparatively easy to produce many specialised shapes to suit various applications, as well as the more traditional shapes shown below.

Note that high-permeability cores (toroids, ferrites, C-Cores and R-Cores) are very unforgiving of DC, and adding an air gap (see next section) is not possible with some. Any DC component in either the primary or secondary will cause partial (unidirectional) saturation, which can cause the core to 'growl'. It also causes much higher than normal 'magnetising' current. It's important to ensure that there is no DC component. For example, a 500VA toroidal transformer can be pushed beyond its VA rating just by using a half-wave rectifier! This will occur at a fraction of the rated output current.

Toroidal

Toroidal cores are made from a continuous strip grain oriented silicon steel, and are bonded to prevent vibration and maximise the 'packing density'. It is important that there are no gaps between the individual layers, which will lower the performance of the core. The sharp corners are rounded off, and they are usually coated with a suitable insulating material to prevent the primary (which is always wound on first) from contacting the core itself.