|

| Elliott Sound Products | Beginners' Guide to Transformers - Part 1 |

Main Index

Main Index

Articles Index

Articles Index

One thing that obviously confuses many people is the idea of flux density within the transformer core. While this is covered in more detail in Section 2, it is important that this section's information is remembered at every stage of your reading through this article. For any power transformer, the maximum flux density in the core is obtained when the transformer is idle. I will repeat this, as it is very important ...

For any power transformer, the maximum flux density is obtained when the transformer is idle.

The idea is counter-intuitive, it even verges on not making sense. Be that as it may, it's a fact, and missing it will ruin your understanding of transformers. At idle, the transformer back-EMF almost exactly cancels out the applied voltage. The small current that flows maintains the flux density at the maximum allowed value, and represents iron loss (see Section 2). As current is drawn from the secondary, the flux falls slightly. The reason for this is due to finite winding resistance and Ohm's law.

It is not important that you understand the reasons for this right from the beginning, but it is important that you remember that for any power transformer, the maximum flux density is obtained when the transformer is idle. Please don't forget this  .

.

Elsewhere on the Net you will find claims that the maximum power available from a transformer is limited by saturation of the core - this is drivel, completely false and must be ignored or you will never understand transformers properly! The information provided here is accurate and correct, and anyone who claims different is wrong! That might sound harsh, but it's true nonetheless.

Something else to ponder is a transformer's inductance. It's commonly believed that a transformer is an inductive load, but ... that is only true at no load or with very light loading. When a transformer is loaded to its rated output with a resistive load, the inductive component is negligible. When any transformer is supplying anything from about 5% up to 100% of its full load current, the inductive component is swamped by the load current, and the phase angle (Φ) between primary voltage and current is minimal. This is all explained more fully below.

With any transformer, the idle current (maximum flux density) is determined by the voltage and frequency. If the frequency is reduced, the maximum voltage that can be applied is also reduced, and vice versa. A transformer designed for 50Hz can be operated at (say) 400Hz, which increases the allowable voltage by a factor of eight. In theory, you could apply a primary voltage of 1.84kV RMS to a 230V/ 50Hz transformer's primary at 400Hz - except you can't. The insulation isn't designed for such a high voltage, and failure is guaranteed.

However, you can use a transformer in reverse to obtain a high voltage (e.g. 300V AC), with the magnetisation current reduced dramatically. This technique is discussed in Project 238 - High Voltage, Low Current DC Source. Rather than a no-load input current of perhaps 100mA or more (at 50Hz for a small transformer), it can be reduced to only a few mA by using a higher than normal frequency. I used 700Hz for my tests. Up to 1kHz will work with most small transformers, but 600-700Hz is a good compromise.

If you double the frequency, you can also double the voltage for the same saturation current. Alternatively, you can use a smaller core, and obtain better performance. Most aircraft systems that operate from AC are run at 400Hz so the transformers are smaller and lighter, but with no loss of performance. This is standard for aircraft systems worldwide.

There is some confusion created by the Wikipedia article discussing toroidal transformers (as of July 2020). Almost everything anyone needs to know is excluded, but there's a lengthy discussion about 'circumferential current'. Firstly, I don't deny that it exists, but I know from many, many years of experience (along with many measurements) that it's irrelevant to 99.9% of users. To me, it looks like the page has been hijacked by someone who either wants to show how clever s/he is, or simply wants to push this particular topic for reasons unknown.

It's worth noting that the references provided on the Wikipedia article are (mostly) useless, with several returning you to the page where the reference is cited. Quite a few people are very unhappy with the page, and one contributor described it as being "like an IBM manual; full of perfectly correct but entirely useless information".

All transformers have some flux 'leakage', and to imagine otherwise is ... unwise. What's important is whether the leaked flux causes any problems with a sensible layout. The answer to this question is "no". Laying even a speaker cable across a toroidal transformer will usually create 'buzz' in the speaker (due to the nonlinear magnetising current), but this isn't the way people wire amplifiers. Likewise, one must avoid laying DC wiring across the top (or immediately adjacent to) any transformer. Flux leakage and/ or circumferential current cause few problems for anyone who understands that the periphery of any transformer is electrically hostile. The only remedial action needed with a toroidal transformer is to maintain a 'safe' distance, which usually needs to be no more than 25mm. If wiring is kept at that distance (or more), interference is usually negligible.

To prove (to myself at least) that I'm not mistaken, I used a 300VA toroidal transformer, and probed it every which way with a single loop detector, amplified 1,000 times (yes, 60dB). I listened to the result through an amplifier & speaker. As expected, leakage flux is greatest where the leads exit, because there's a discontinuity created when the leads are brought out of the windings. The probe loop had to be within 10mm or so from the windings to detect anything significant. Poking the probe loop inside the hole in the middle of the transformer gave the highest reading, but that space is only ever used for a mounting bolt.

Now, what I haven't done is show the waveforms and amplitude, nor have I attempted to measure the current that can be developed in a low-resistance loop. I haven't done these things for one simple reason - there is no point. We know there will be flux leakage and/ or 'circumferential current', but we don't care. It doesn't change a thing, and we can all continue using toroidal transformers as if these things didn't exist. It might be important for some switching applications where it's difficult to completely surround the core with windings, and there might be some other applications where it matters. Audio power supplies are not affected in any way!

This article concentrates on transformers used for typical electronics projects, power supplies and similar. It does not cover large transformers used in substations and the mains grid in general (other than in passing), although the factors discussed are also applicable to these much larger transformers. In engineering, the transformer is one of the most efficient machines we have at our disposal, but those used for distribution and industry are a (large) step up from the ones we normally work with.

The underlying basics that allow us to make use of electro-magnetism were only discovered in 1824, when Danish physicist Hans Oersted found that a current flowing through a wire would deflect a compass needle. A few years after this, it was found that a moving magnetic field induced a current into a wire. From this seemingly basic concept, the field of electromagnetism has grown to the point that society as we know it would not exist without the many machines that make use of these discoveries.

The principles of magnetic induction are covered by Faraday's law, named after Michael Faraday, the British scientist who first quantified the processes involved (1831). The basic principles were independently discovered by Joseph Henry (after whom the unit of inductance is named) in 1832. Faraday's 'law of induction' covers the way in which a (non static) magnetic field induces a current into a wire, and conversely, how a current in a wire creates a magnetic field. Transformers rely on the principle of a constantly changing magnetic field (created by alternating current flowing in the primary winding) that interacts with the secondary, generating an AC voltage (and current when loaded) into the secondary. Faraday's experimental data were converted into equations by James Clerk Maxwell, and were added and further expanded upon by Oliver Heaviside. Emil Lenz formulated the concept of 'back-EMF' (electromotive force), where the polarity of the current in a wire (or winding) creates a magnetic field that opposes the magnetic field applied to the winding (1834).

These concepts are all important, but fortunately a complete understanding of the various laws and formulae is not necessary to work out how a transformer works. I say 'fortunately', because many of the calculations are extensive and difficult for most non-mathematicians to work with. The majority aren't even a requirement if one is designing transformers, especially since there are many 'rules-of-thumb' that are commonly applied during the design phase, simplifying the process.

As you look through this article, you may be excused for exclaiming "This is for beginners? - the man's mad. Mad, I tell you!" This is probably fair comment, but transformers are not simple, and there is no simple way to provide all the information you need to understand them properly. There are sections here that probably go a little bit deeper than I originally intended, but were just too interesting to leave out. While it might not look like it, the info here is simplified. This is not a tutorial on magnetic theory or a deep discussion of flux density and how it's calculated. These topics are not a requirement for understanding how a transformer works or what you can do with it.

There are parts of this article you may want to skip over, but I suggest that you do read all of it if you can. A full understanding to the extent where you can design your own transformer is not the aim, but the majority of the information is at the very least interesting, and will further your general electronics knowledge.

For those who wish to delve deeper, Section 2 does just that. It is recommended reading, even for beginners, as there is a great deal to be learned about transformers, despite their apparent simplicity.

Transformers are essential for all modern electronics equipment, and there are very few devices that do not use them. Each transformer type has a specific use, and it is uncommon that a transformer made for one application can be used for another (quite different) purpose. This is not to say that 're-purposing' can't be done, but you have to know what you are doing, and what risks may be waiting to cause grief.

Before embarking on a description of the different types, the basic theory must be understood. All transformers use the same basic principle, and only the finer points ever change. A transformer works on the principle of magnetic coupling to transfer the energy from one side (winding) to the other.

Transformers are bi-directional, and will work regardless of where the input is connected. They may not work as well as they otherwise might, but basic functionality is unchanged. An ideal transformer imposes no load on the supply (feeding the primary) unless there is a load across the secondary - real life components have losses, so this is not strictly true, but the assumption can be used as a basis of understanding.

Power transformers are rated in Volt-Amps (VA). Using Watts is of no use, since a load that is completely reactive dissipates no power, but there are still Volts and Amps. It is the product of 'real' voltage and current that is important - a wattmeter may indicate that there is little or no real power in the load, but the transformer is still supplying a voltage and a current, and will get hot due to internal losses regardless of the power.

Transformer cores have a quoted permeability, which is a measure of how well they 'conduct' a magnetic field. Magnetism will keep to the path of least resistance, and will remain in a high permeability core with little leakage. The lower the permeability, the greater is the flux leakage from the core (this is of course a gross simplification, but serves well enough to provide an initial explanation of the term).

A transformer may be made with various materials as the core (the magnetic path). These include ...

Permeability is stated above as 'initial permeability' - the actual permeability of core materials other than air (written as µ i). It is a 'small-signal' parameter, and almost always reduces at significant flux levels. The characteristics (effective permeability - µ e) vary with the material and field strength, and this is not covered here. See Terms and Definitions (From Hitachi Metals) if you want more complete explanations.

Technically, powdered iron and ferrites are both classified as soft (see below) ferrites, but they have very different characteristics, even within the same 'family'. They are generally unsuitable for low frequency operation, except at low levels. Ferrites are often used as signal transformers (such as isolation transformers for telecommunications or other small signal applications), where the high permeability makes them an ideal choice for small size and high inductance.

Core materials are generally classified as 'soft' - this has nothing to do with their physical properties (they are all hard to very hard), but is a reference to their ability to retain magnetism (remanence). A soft magnetic material has low remanence and is difficult to magnetise. Hard magnetic materials are used for 'permanent' magnets, and they have a very high remanence, which is to say they retain a very large proportion of the original magnetic field that was induced into them during manufacture.

All switchmode power supplies use ferrite transformers, since conventional laminations cannot be made thin enough to prevent huge eddy-current losses in the core. Many limitations exist in any core material. For low frequency power applications, grain-oriented silicon steel (about 4% silicon) is by far the most common, as it has a very high flux density before saturation. Most other materials are inferior in this respect, one of the main reasons this material is still so common. Specialised material include MuMetal (aka µMetal, Mu-Metal, etc.) and Permalloy, and these are very high permeability core (and magnetic shielding) materials.

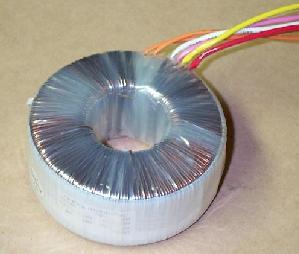

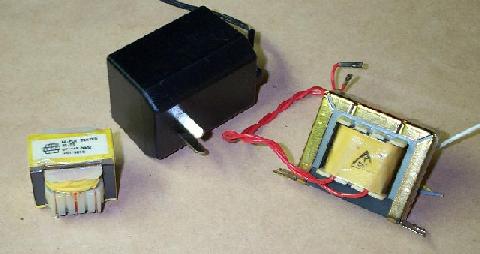

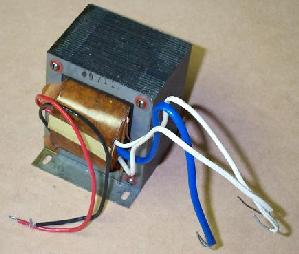

Toroidal |  Split Bobbin E-I Plug-Pack Conventional E-I |  E-I |

A small sample of some transformers is shown above (not to scale). The toroidal and E-I transformers are the same power rating, and a small selection of little transformers and a plug-pack (wall transformer, wall-wart, etc) are shown as well.

There are two types that are sufficiently different from those shown that they deserve some explanation. 'R-core' transformers do not use a core shaped like the letter 'R', but are closely related to C-Cores, which are described elsewhere in this series. The core cross-section is circular (i.e. 'round'), and the bobbin is permanently installed. There's more detail in Transformers, Part II (Section 13), and C-Cores are also covered in the same section.

One type that I haven't covered is the 'planar' transformer. These are very low-profile, and shaped somewhat like a large IC. The magnetic materials are above and below the windings that are often created on a thin PCB, enclosed by the ferrite 'core'. It's not really a core, in that the windings are fully enclosed. In some cases, one (or more) 'windings' are part of a PCB, with cutouts for the core pieces to be installed. These are specialised, and most are only suitable for high-frequency applications, because they have low inductance. Don't expect to see them specified in any ESP project. To get an idea of the possibilities, do an image search for 'planar transformer'.

The transformer is essentially just two (or more) inductors, sharing a common magnetic path. Any two inductors placed reasonably close to each other will tend to work as a transformer, and the more closely they are coupled magnetically, the more efficient they become. This is why passive loudspeaker crossover networks must have the inductors oriented in different ways - to prevent them from acting as a transformer.

When a changing magnetic field is in the vicinity of a coil of wire (an inductor), a voltage is induced into the coil which is in sympathy with the applied magnetic field. A static magnetic field has no effect, and generates no electrical output. The same principles apply to generators, alternators, electric motors and loudspeakers, although this would be a very long article indeed if I were to cover all the magnetic field devices that exist.

When an electric current is passed through a coil of wire, a magnetic field is created - this works with AC or DC, but with DC, the magnetic field is obviously static. For this reason, transformers cannot be used directly with DC, because although a magnetic field exists, it must be changing to induce a voltage into another coil. A static magnetic field cannot produce an output voltage/ current.

Try this experiment. Take a coil of wire (a loudspeaker crossover coil will do nicely for this), and a magnet. Connect a multimeter - preferably analogue) to the coil, and set the range to the most sensitive current range on the meter. As you move the magnet towards or away from the coil, you will see a current, shown by the deflection of the meter pointer. As the magnet is swung one way, the current will be positive, the other way - negative. The higher the coil's inductance and the stronger the magnet (and/ or the closer it is to the coil), the greater will be the induced current.

Move the magnet slowly, and the current will be less than if it is moved quickly. Leave it still, and there is no current at all, regardless of how close the magnet may be. This is the principle of magnetic induction, and it applies to all coils (indeed to all pieces of wire, although the coil makes the effect much greater).

If you now take a handful of nails and place them through the centre of the coil, you will see that the current is increased many times - the magnetic field is now more concentrated because the steel nails make a better magnetic path (higher permeability) than air.

The ease with which any material can carry a magnetic field is called permeability (or more correctly, initial permeability), and different materials have differing permeabilities. Some are optimised in specific ways for a particular requirement - for example the cores used for a switchmode power supply transformer are very different from those used for normal 50/60Hz mains transformers.

The permeability of transformer cores varies widely, depending on the material and any treatment that may be used. The permeability of air is 1, and most traditional cores have a much higher (i.e. > 1) permeability. A couple of notable exceptions are aluminium and brass, which are sometimes used to reduce the inductance of air cored coils in radio frequency (RF) work. This is much less common than a ferrite 'slug' core, which increases the inductance and is used to tune many RF transformers.

As well as permeability, magnetic cores (with the exception of air) have a maximum magnetic flux they can handle without saturation. In this context, saturation means the same as in most others - when a towel is saturated, it can hold no more water, and when a magnetic core is saturated, it can carry no more magnetic flux. At this point, the magnetic field is no longer changing, so current is not induced into the winding.

You will probably be unable to saturate your nails with the magnet, as there is a very large air gap between the two pole pieces. This means that the core will always be able to support the magnetic flux, but the efficiency is also very much lower because the magnetic circuit is open. Nearly all the transformers you will see have a completely closed magnetic circuit, to ensure that as much of the magnetism induced into the core as possible will pass through the winding(s).

There are some cases where a tiny air gap will be left deliberately, and this is done routinely when a transformer or coil must sustain a significant DC component as well as the AC. This is covered briefly below, but there is more on this subject in the second section of the article.

Figure 1.1 shows the basics of all transformers. A coil (the primary) is connected to an AC voltage source - typically the mains for power transformers. The flux induced into the core is coupled through to the secondary, a voltage is induced into the winding, and a current is produced through the load.

The diagram also shows the various parts of a transformer. This is a simple transformer with two windings. The primary (denoted as such during the design) will induce a magnetic field into the core in sympathy with the current produced by the applied AC voltage. The magnetic field is concentrated by the core, and nearly all of it will pass through the windings of the secondary as well, where a voltage is induced. The core in this case is typical of the construction of a 'C-Core' transformer, where the primary and secondary are sometimes separated. More common is the 'traditional' E-I (ee-eye) type, which although somewhat out of favour these days is still used extensively. This is shown below.

The magnitude of the voltage in the secondary is determined by a very simple formula, which determines the turns ratio (N) of the component - this is traditionally calculated by dividing the secondary turns by the primary turns ...

1.1.1 N = Ts / Tp

Tp is simply the number of turns of wire that make up the primary winding, and Ts is the number of turns of the secondary. A transformer with 500 turns on the primary and 50 turns on the secondary has a turns ratio of 1:10 (i.e. 1/10 or 0.1)

1.1.2 Vs = Vp × N

Mostly, you will never know the number of turns, but it can be determined by adding a small winding of (say) 5 turns if space allows. With a known primary voltage, the voltage measured across the extra winding can be used to calculate the turns/ volt. For example, if you measure 2V across 5 turns, the transformer has 2.5 turns/ volt, so a 230V primary will use 575 turns. We can simply reverse the above formula so that the turns ratio can be deduced from the primary and secondary voltages ...

1.1.3 N = Vs / Vp

If a voltage of 230V (AC, naturally) is applied to the primary, we would expect 23V on the secondary, and this is indeed what will be measured. In most cases it will be a little higher (perhaps 25V or so) to allow for losses under load. The transformer has an additional useful function - not only is the voltage 'transformed', but so is the current.

1.1.4 Is = Ip / N

If a current of 10A were drawn from the secondary in the above example, then logically a current of 1A would be measured in the primary - the voltage is reduced, but current is increased. This would be the case if the transformer were 100% efficient, but even this - the most efficient 'machine' we have - will sadly never be perfect. As a result, when drawing 10A from the secondary, the voltage will be less than the 23V we had with no load. This is a measure of the transformer's regulation, and the great majority of the voltage drop is due to winding resistance.

With large transformers used for the national supply grid, the efficiency of the transformers will generally exceed 95%, and some will be as high as 98% (or even more).

Smaller transformers will always have a lower efficiency, but those commonly used in power amplifiers can have efficiencies of up to 90% for larger sizes. The reasons for the lost power will become clear (I hope) as we progress. For the time being, we shall consider the transformer to be 'ideal' (i.e. having no losses) for simplicity.

The conventional E-I lamination set is still extensively used, and a few pertinent points are worth mentioning. The centre leg is always double the width of the outer legs to maintain the cross-sectional area. Likewise, the 'I' lamination and the 'back' of the E are the same width as (or sometimes slightly larger than) the outer legs. The winding window is where the copper windings live, and in a well designed transformer will be almost completely full. This maximises the amount of copper and reduces resistive losses because the windings are as thick as they possibly can be.

See Section 2 to see how the dimensions of the E and I laminations are determined. This is commonly referred to as 'scrapless' lamination, and almost eliminates any wasted material.

This list is far from complete, but will be sufficient to either get you started or scare you away. I have included the symbols and units of only three of the entries below, since most are of no real interest.

Coercivity - is the field strength which must be applied to reduce (or coerce) the remanent flux to zero. Materials with high coercivity (e.g. those used for permanent magnets) are called hard. Materials with low coercivity (those used for transformers) are called soft.

Effective Area - of a core is the cross sectional area of the centre limb for E-I laminations, or the total area of the magnetic circuit for a toroid. Usually this corresponds to the physical dimensions of the core but because flux may not be distributed evenly the manufacturer may specify a value which reflects this.

Effective length - of a core is the distance which the magnetic flux travels in making a complete circuit. Usually this corresponds closely to the average of the physical dimensions of the core, but because flux has a tendency to concentrate on the inside corners of the path the manufacturer may specify a value for the effective length.

Flux Density - (symbol; B, unit; Teslas (T)) is simply the total flux divided by the effective area of the magnetic circuit through which it flows.

Flux linkage - in an ideal inductor the flux generated by one turn would be contained within all the other turns. Real coils come close to this ideal when the other dimensions of the coil are small compared with its diameter, or when a suitable core guides the flux through the windings.

Magnetomotive Force - MMF can be thought of as the magnetic equivalent of electromotive force. It is the product of the current flowing in a coil and the number of turns that make up the coil.

Magnetic Field Strength - (symbol: H, unit; ampere metres (A m-1)) when current flows in a conductor, it is always accompanied by a magnetic field. The strength, or intensity, of this field is proportional to the amount of current and inversely proportional to the distance from the conductor (hence the -1 superscript).

Magnetic Flux - (symbol: Φ; unit: Webers (Wb)) we refer to magnetism in terms of lines of force or flux, which is a measure of the total amount of magnetism.

Permeability - (symbol; µ, units: henrys per metre (Hm-1) is defined as the ratio of flux density to field strength, and is determined by the type of material within the magnetic field - i.e. the core material itself. Most references to permeability are actually to 'relative permeability', as the permeability of nearly all materials changes depending upon field strength (and in most cases with temperature as well).

Remanence - (or remnance) is the flux density which remains in a magnetic material when the externally applied field is removed. Transformers require the lowest possible remanence, while permanent magnets need a high value of remanence.

Saturation - The point where the core can no longer accept more flux. When this occurs, the transformer primary current is limited only by any series resistance (external and winding resistances for example). Core saturation limits the peak AC input voltage for a given number of primary turns. The onset of saturation is usually fairly gradual, but can be very abrupt with some high permeability materials. This is particularly noticeable with toroidal cores.

I mention these here for the sake of completeness, but their real importance is not discussed further in this section. Section 2 of this article revisits the terms, and their importance is somewhat enhanced in context.

At no load, an ideal transformer draws virtually no current from the mains, since it is simply a large inductance. The whole principle of operation is based on induced magnetic flux, which not only creates a voltage (and current) in the secondary, but the primary as well! It is this characteristic that allows any inductor to function as expected, and the voltage generated in the primary is called a 'back EMF' (electromotive force). The magnitude of this voltage is such that it almost equals (and is effectively in the same phase as) the applied EMF.

Although a simple calculation can be made to determine the internally generated voltage, doing so is pointless since it can't be changed. For a sinusoidal waveform, the current through an inductor lags the voltage by 90 degrees. Since the induced current is lagging by 90 degrees, the internally generated voltage is shifted back again by 90° so is in phase with the input voltage. For the sake of simplicity, imagine an inductor or transformer (no load) with an applied voltage of 230V. For the effective back EMF to resist the full applied AC voltage (as it must), the actual magnitude of the induced voltage (back EMF) is just under 230V. The output voltage of a transformer is always in phase with the applied voltage (within a few thousandths of a degree).

For example ... a transformer primary operating at 230V input draws 15mA from the mains at idle and has a DC resistance of 2 ohms. The back EMF must be sufficient to limit the current through the 2 ohm resistance to 15mA, so will be close enough to 229.97V (30mV at 2 ohms is 15mA). In real transformers there are additional complications that increase the total current (iron loss and/or partial saturation in particular), but the principle isn't changed much.

If this is all too confusing, don't worry about it. Unless you intend to devote your career to transformer design, the information is actually of little use to you, since you are restrained by the 'real world' characteristics of the components you buy - the internals are of little consequence. Even if you do devote your life to the design of transformers, this info remains merely a curiosity for the most part, since there is still little you can do about it.

When you apply a load to the output (secondary) winding, a current is drawn by the load, and this is reflected through the transformer to the primary. As a result, the primary must now draw more current from the mains. Somewhat intriguingly perhaps, the more current that is drawn from the secondary, the original 90° current phase shift becomes less and less as the transformer approaches full power. The power factor of an unloaded transformer is very low, meaning that although there are volts and amps, there is relatively little power. The power factor improves as loading increases, and at full load will be close to unity (the ideal).

However, this depends on the load - a non-linear load on the transformer's secondary reflects a non-linear load to the mains supply.

Now, another interesting fact about transformers can now be examined.

We will use the same example as above. A 230V primary draws 1A, and the 23V secondary supplies 10A to the load. Using Ohm's law, the load resistance (impedance) is therefore 23/10 = 2.3 Ohms. The primary impedance must be 230/1 = 230 Ohms. This is a ratio of 100:1, yet the turns ratio is only 10:1 - what is going on?

The impedance ratio of a transformer is equal to the square of the turns ratio ...

3.1.1 Z = N²

Likewise, if you know the impedance ratio (e.g. for a valve output or microphone transformer), the turns ratio and therefore the voltage ratio is determined by the square root of the impedance ratio ...

3.1.2 N = √Z

Transformers are usually designed based on the power required, and this determines the core size for a given core material. From this, the required 'turns per volt' figure can be determined, based on the maximum flux density that the core material can support. Again, this varies widely with core materials.

A rule of thumb can be applied, that states that the core area for 'standard' (if indeed there is such a thing) steel laminations (in square centimetres) is equal to the square root of the power. Thus a 625VA transformer would need a core of (at least) 25 sq cm, assuming that the permeability of the core were about 500, which is fairly typical of standard transformer laminations. This also assumes that the core material will not saturate with the flux density required to obtain this power.

The next step is to calculate the number of turns per volt for the primary winding. This varies with frequency, but for a 50Hz transformer, the turns per volt is (approximately) 45 divided by the core area (in square centimetres). Fewer turns are needed for a 60Hz transformer, and the turns per volt will be about 38 / core area. Higher performance core materials may permit higher flux densities, so fewer turns per volt might be possible, thus increasing the overall efficiency and regulation. These calculations must be made with care, or the transformer will overheat at no load.

For a 625VA transformer, it follows that you will need about 432 turns for a 230V primary, although in practice it may be less than this. The grain-oriented silicon steels used in better quality transformers will often tolerate higher total flux per unit area, and fewer turns will be needed.

You can determine the turns per volt of any transformer (for reasons that will become clearer as we progress) by adding exactly 10 turns of thin 'bell wire' or similar insulated wire to the transformer to be tested, wound over the existing windings. When powered from the correct nominal supply voltage, measure the voltage on the extra winding you created. Divide the number of turns (10) by the voltage measured to obtain the turns per volt figure for that transformer. For example, if you measure 5V, the transformer has 2 turns/volt.

Now, what earthly use is this to you? Well, you might be surprised at what you can do with this knowledge. Assume for a moment that you have a transformer for a fair sized power amplifier. The secondary voltage is 35-0-35V which is much too high to power the preamp circuit or even its power supply - but you will be able to do that with a single 16V winding. Another transformer would normally be used, but you can also add the extra winding yourself. This is almost too easy with toroidal transformers, but with others it may not be possible at all. If the transformer uses (say) 2 turns per volt, a mere 32 extra turns of bell wire (or enamelled copper wire) will provide 16V at the typical 100mA or so you will need. Add a 10% margin, and you still have only 36 turns to add, and this can be done in a few minutes. Make sure that the extra winding is securely taped down with a good quality tape (Kapton is highly recommended if you can get it). Do not use ordinary electricians' tape - it is not designed for the temperature that transformers may operate at under consistent load.

NOTE: Ensure that there is no possibility whatsoever of the added winding shorting between turns - this will cause the smoke to escape from the insulation in a spectacular fashion, and you may ruin the transformer itself.

The magnetising current quoted or measured for any transformer is usually a combination of true magnetising current (which is usually very low) and saturation current, which can be up to half the calculated full load current for small transformers. Any transformer with a core (silicon steel, ferrite, etc.) will saturate if the no-load primary voltage is increased far enough. This is covered in much greater detail in Part 2, Section 12.1.

Core saturation is reached when the peak input voltage is sufficient to cause the core to reach its maximum rated flux. When the flux density is too high the core can no longer accept more, and it saturates. The saturation waveform is shown in Section 2, and although you may see the transformer's 'magnetising current' specified, this is almost always the no-load primary current, including saturation current.

It is unrealistic to expect any mains transformer to remain well below saturation at all operating levels. This would require the core to be a great deal larger and more expensive than normal. When the core flux density exceeds around 1.4 Teslas (silicon steel) it is starting to saturate. Once the core is fully saturated it effectively no longer exists, and current is limited only by the circuit resistance. This cannot be allowed, but partial saturation at idle is common, and this increases the apparent magnetising current.

For transformers used in audio (valve output transformers, microphone or 'line' transformers, etc.) the core must be operated well below saturation at all possible voltages and frequencies to prevent serious distortion. For power transformers, a small amount of saturation at no load is common. While this increases the no-load current (and temperature) of the transformer, it also allows for slightly better regulation because fewer turns are used which reduces winding resistance.

Saturation is a complex process and is not well understood by most hobbyists (and even some professionals). The degree of allowable saturation depends on the intended usage, and how much distortion can be tolerated. As the frequency is reduced, a transformer will saturate more if the input voltage is kept the same. For example, a power transformer designed for 60Hz operation will usually saturate heavily at 50Hz, even if the voltage is correct. Normal operation can only be restored if the input voltage is reduced by the same ratio as the frequency - 60Hz to 50Hz is 17%, so the input voltage must also be reduced by 17% to get the designed 'magnetising' current.

As discussed above, the impedance ratio is the square of the turns ratio, but this is only one of many interesting things about transformers ... (well, I happen to think they are interesting, anyway  ).

).

For example, one would think that increasing the number of turns would increase the flux density, since there are more turns contributing to the magnetic field. In fact, the opposite is true, and for the same input voltage, an increase in the number of turns will decrease the flux density and vice versa. This is counter-intuitive until you realise that an increase in the number of turns increases the inductance, and therefore reduces the current through the winding.

I have already mentioned that the power factor (and phase shift) varies according to load, and this (although mildly interesting) is not of any real consequence to most of us.

A very interesting phenomenon exists when we draw current from the secondary. Since the primary current increases to supply the load, we would expect that the magnetic flux in the core would also increase (more amps, same number of turns, more flux). In fact, the flux density decreases! In a perfect transformer with no copper loss, the flux would remain the same - the extra current supplies the secondary only. In a real transformer, as the current is increased, the losses increase proportionally, and there is slightly less primary voltage (due to the copper resistance), so flux at full load is lower than at no load. It's worth making a bit of noise about this, as it is widely misunderstood. Although already pointed out at the beginning, it's so important that I'll state it again ...

The flux density in a transformer is greatest at no load, and it decreases as load is increased.

When you test a transformer with no load, the primary current is solely due to magnetising current and an additional current caused by partial saturation (almost all mains transformers will show some evidence of saturation current - see Part 2, Section 12.1). Let's assume that the transformer is operating from 230V on the primary, and it has a primary winding resistance of 10Ω. If we now connect a load to the secondary that causes the primary current to rise to 1A, the effective primary voltage is reduced by 10V (10Ω × 1A), so it falls to 220V. The flux density is reduced proportionally, and with a lower effective voltage, flux density must be lower when current is drawn from the secondary.

The flux density from the secondary has no effect because any additional flux created by the load current is equal but opposite to that caused by the primary current, because the direction of current flow is opposite (Fleming's right hand rule). This is (IMO) a 'peripheral' topic, and it explains why the secondary current doesn't increase the flux density. The real reason that flux density falls is purely due to winding resistance. A transformer using 'superconductors' (zero ohms) for primary and secondary would maintain the same flux regardless of load current.

It's also important to understand another interesting fact about

Let's assume a 600VA toroidal transformer, having a measured inductance of 52H at 50Hz. The formula for inductance tells us that the magnetising current will be ...

4.1.1 Imag = V / ( 2π × f × L )

4.1.2 Imag = 230 / ( 2π × 50 × 52 ) = 14mA

However, when this transformer is tested (see Part 2 - Magnetising Current), the magnetising current is actually measured at 42mA - 3 times higher than expected. This happens because the core is partially saturated, not because the inductance is lower than measured or calculated. If operated at a (much) lower voltage where the magnetising current is undistorted (meaning there is no core saturation at all), the magnetising current obeys the formula shown above. Without core saturation, the current is determined by the inductance, voltage and frequency, as with any inductor. However, (most) transformers are not inductors as such!

Note: For many other transformers, inductance is a design parameter (and an important one). This applies to transformers used in switchmode power supplies, or for audio transformers and others where low frequency response is critical. It's only with mains frequency transformers (50 or 60Hz) where we don't really care about the inductance, provided the magnetising current is sensible. 'Sensible' is determined by how and where the tranny is used, and what the designer wanted to achieve. There are no 'rules' here - if it works as required (and according to the design specification), remains at an acceptable temperature and is reliable and safe, then that's all that matters.

That is why manufacturers rarely (if ever) specify the inductance of mains frequency transformers. Instead (and if you're lucky), they might tell you the no load magnetising current at rated voltage and frequency. Most don't even bother to tell you that much. After all, there's nothing you can do about it anyway.

In the preface, I mentioned that a transformer is not inductive when driving its rated load. If we imagine the same transformer described above (52H of inductance) it will draw 14mA of inductive current at idle (ignoring saturation). The current will lag the voltage by 90°, and the power factor determined by cos(Φ) is cos(90) = 0. If the secondary is loaded such that the primary load current is just 14mA (total current is now 20mA, not 28mA as you might assume), the phase angle falls to 45° and power factor is increased to cos(45) = 0.707 - with only 14mA of load current!

Once the load is such that the primary current is around 5% or more of the transformer's rating (about 130mA for a 600VA transformer), the phase shift is only a few degrees (about 5.6°) and power factor is close to unity (0.995 for the hypothetical transformer discussed). However (and this is important), the primary current is an almost perfect reproduction of the secondary current, and if the secondary current is non-linear, so too is the primary current. Rectifier and capacitor loads as used in nearly all linear power supplies have a poor power factor, but it's due to non-linearity, and not inductance.

So, for normal mains transformers, inductance is not part of the specification and may be considered 'incidental'. It has to exist to limit the no load current to a reasonably sensible value, but the greatest proportion of the magnetising current is due to partial saturation. Most mains transformers have to be tested at a voltage well below their specified mains input voltage to be able to measure the inductance. A typical 230V transformer will need to be measured at no more than around 50-100V to obtain the actual inductance.

Having measured the primary inductance, you quickly discover that the measurement is useless - you can't do anything with it, and it doesn't help your understanding one iota. This is partly due to the simple fact that it changes. As the flux density within the core is varied, so too is the measured inductance, so it really is a pointless parameter in the greater scheme of things. Transformers are designed to obtain the voltage and current desired at the secondary, and the design process is based on the number of primary turns needed to get a sensible no-load ('magnetising') current.

It's largely a balancing act. For a given core size, a higher magnetising current is the result of using fewer turns on the primary, and that improves regulation because the wire can be larger. However, if the no-load current is too high, the transformer will overheat because the core saturates, due to the high primary current. A transformer that is never operated at no load can be designed to be far smaller than otherwise.

If we assume that a transformer for a particular application must provide good regulation and that it is only ever operated at full load, there is no reason to make the core as large as would otherwise be necessary. We can also use fewer turns and reduce resistive losses. Modern microwave oven transformers fall into this category - if they are operated with no load, the magnetising current can be so high that the transformer would overheat and fail, but when run normally (powering a magnetron), they are perfectly suited to the job. Most are also fan cooled, allowing them to be smaller still!

When a transformer is only operated at full load, magnetising current is no longer a major consideration, and the number of turns needed is based on the effective voltage across the winding at full load. A 1kW transformer might normally have a primary resistance of around 1.0 to 1.2 ohms, but if that can be reduced, copper loss is also reduced. At 1kW, the primary current is 4.35A, and that would reduce the voltage seen by the transformer by perhaps 5 to 6V RMS. Rather than designing the transformer for a nice low magnetising current at 230V, it can be designed for a somewhat higher magnetising current at 225V - magnetising current alone might be as much as 1 or 2A - perhaps more.

Attempting to measure the inductance of such a transformer is a waste of time. You will be able to measure it, but the reading has no meaning. Even more conventional mains transformers are in the same boat - the inductance can (perhaps - at a stretch) be considered a 'figure of merit', but the only thing that really matters is the total magnetising current, including the effects of partial saturation. Don't imagine for one minute that normal mains transformers don't saturate - every transformer I have ever measured will draw between 2 to 5 times the current you'd expect based on the inductance alone. Of course, at normal operating voltages the two are inseparable.

The inductance ratio of any transformer (between primary and secondary) is the square of the turns ratio. A transformer designed for 230V mains with a measured output voltage of 23V at no load (20V full load) has a turns ratio of 10:1 (230:23). If you measure the primary inductance at (say) 30H, the secondary inductance is 300mH. This isn't useful either, but it might come in handy if you wish to use the transformer in reverse, driven from an oscillator and power amplifier for example.

One of the things that tends to cause confusion relates to how the transformer 'knows' that someone is trying to draw current from the secondary, so primary current can be increased in proportion. This is due to the mutual inductance (aka mutual coupling or just coupling factor) between the windings. When two or more windings share the same magnetic circuit, the two are coupled by the flux. In an ideal transformer this coupling is unity, meaning that any perturbation on one winding is directly coupled to the other (allowing for transformation ratio of course).

If the coupling is unity, the windings act as one. The electrical separation (insulation) is of no consequence, so an attempt to draw current from the secondary is no different from drawing current from the primary - the two windings are linked together and are inseparable. Of course, real transformers are not ideal, but (perhaps surprisingly) that only changes things slightly. This is the key to transformer operation, but (despite its great importance) it has little influence on the transformer design. It's also something that you can't change - the transformer is what it is, and parameters can only be changed at design time.

Leakage inductance reduces the mutual inductance, preventing unity coupling. However, this doesn't actually change anything much in mains frequency transformers. Even 'conventional' (E-I lamination) transformers have comparatively low leakage inductance (compared to primary inductance), and toroidal types have very low leakage inductance. Any flux that 'leaks' from the core is unable to pass through the two windings equally, thus reducing the effective flux in the secondary and reducing the coupling between them.

The coupling is such that if you were to drive a mains transformer from a low impedance signal generator, anything on the secondary is reflected back to the primary. If the load is a capacitor, the primary will appear to be capacitive (leading power factor). When the load is a resistor, the primary appears to be resistive. The primary will be inductive only if the load is an inductor. To run this test (which is not difficult to do), the current drawn from the secondary has to be at least 10 times (and preferably 100 times) greater than the magnetising current (the no load current due to the transformer's primary inductance.

For example, if the transformer has a primary inductance (at low voltage) of 100H, the magnetising current will be about 390µA at 50Hz. You need to draw at least 39mA from the secondary, and that's enough to cause the primary voltage and current to be within less than one degree of each other. If you now connect a capacitor that draws the same current (this needs to be calculated based on the voltage and frequency) the primary appears to be entirely capacitive.

This is an aspect of mutual coupling that is rarely explained, but understanding this simple concept means that you can avoid a whole bunch of rather tedious maths that won't actually help you to understand the principles involved. As regular readers know, I won't provide extensive formulae if they don't help anyone to figure out how something works. This is a case in point. Throwing a formula at this will reveal almost nothing, but if you run the test for yourself, you will understand how it works.

A transformer does not have a defined impedance. You can be excused for thinking otherwise, but that's because some transformers are designed for valve amplifier output stages or for nominal 600 ohm signal lines (for example). For an output transformer, the impedance ratios are determined to match the anode resistance/ impedance of particular output valves, and convert that to an impedance suitable for a loudspeaker. In this role, the inductance of the primary winding is important, because it needs to be high enough to ensure good coupling between the valves and speakers at the lowest frequency of interest.

This is covered briefly in this section, and is examined in more detail in Section 2. While the inductance is important, it's even more important to ensure that the core remains well away from even partial saturation at the lowest frequencies. This is why good output transformers are so large and expensive. However, it's important to understand that while the transformer is designed and advertised as being (for example) 6kΩ P-P : 8Ω, that doesn't mean that the transformer itself has these impedances. What it does mean is that when driven from a 6kΩ source (a pair of output valves) the output impedance will be such that maximum power is delivered to an 8Ω load.

The exact same transformer can be fed from a 3kΩ source, and deliver maximum power into a 4Ω load. It also works with higher source impedances, but then the inductance may not be great enough to ensure good bass response. The required inductance is determined by the source impedance and the lowest frequency of interest - typically 40Hz for many valve amps. So, using the example given, the inductance and -3dB frequency can be determined ...

4.3.1 L = Z / ( 2π × f-3dB ) (Where Z is source impedance and f-3dB is the -3dB frequency)

4.3.2 L = 6k / ( 2π × 40 ) = 24H

As should be apparent, as the source impedance is increased, more inductance is required for the same -3dB frequency. This also requires that the core flux is kept well below saturation. Even a small amount of saturation causes gross distortion. There are some claims that this distortion is not as objectionable as might be imagined, because it falls off with increasing frequency. However, if a low and high frequency are passed simultaneously, the higher frequency will be distorted as well - once the core starts to saturate, all frequencies present at the time are distorted, not just the frequency that causes saturation.

Impedance Ratio

While a transformer doesn't have a defined impedance as such, it may be designed to function at its best with a specific impedance. For example, an audio transformer made be designed to operate at a nominal impedance of 600Ω. All this means is that it has sufficient inductance to ensure that it can support the design voltage without saturating. Higher impedances mean more inductance, as the inductance must be high enough to impose a minimal load on the source at the lowest frequency of interest.

For a 600Ω transformer capable of handling a minimum frequency of 40Hz, the minimum inductance will typically be at least 5H, preferably (much) higher. The impedance (inductive reactance) of 5H at 40Hz is 1,256Ω, roughly double the design impedance. When the inductive reactance is equal to the nominal impedance, the response is 3dB down from the mid-band amplitude. In general, the inductance of audio transformers will be as high as possible, consistent with a ;sensible' resistance (which should be low). A more-or-less typical 10k mic transformer will likely have an inductance of 40H or more, to allow for operation down to 20Hz at a 'sensible' level.

4.3.3 XL = 2π × f × L

4.3.4 XL = 2π × 40 × 5 = 1,256Ω

All transformers have an impedance ratio, regardless of whether they are designed for power or signal. The turns ratio is a given - it must exist for any transformer, and the impedance ratio is the square of the turns ratio. A transformer with 1,000 primary turns and 100 secondary turns creates a voltage ratio of 10:1, and an impedance ratio of 100:1.

4.3.5 Zratio = Tratio²

4.3.6 Zratio = 10² = 100

Likewise, if you know the impedance ratio you can determine the turns ratio. The turns ratio is simply the square root of the impedance ratio. For example, a 10k:600Ω transformer has an impedance ratio of 16.7:1, so the turns ratio is √16.7 = 4.08:1. If you apply 1V to the 10k primary, the output is 245mV. With this information, you can characterise any transformer fairly easily, based on the readily determined turns ratio. The calculations can be used with any transformer.

This is only a brief discussion of the many uses of transformers. I have avoided switchmode supplies in this section, and will only present the most common linear applications. Power supply applications are covered more fully in Section 2, and also in the article on Linear Power Supply Design.

It would be impossible to cover all aspects of transformers and their uses, since they are so diverse and are used in so many different things. Computer network interface cards, modems, through to power amplifiers and microwave ovens, car and marine ignition systems, Tesla coils and moving coil phono preamps, power distribution from the power station to your home ... this is a very small sampling of the diversity of the humble transformer (well, maybe it is not so humble after all  ).

).

Apart from the obvious uses in power supplies, transformers are used in other areas as well. Valve (vacuum tube) power amplifiers nearly all use a transformer for the output stage, and this converts the high impedance of the anodes to the loudspeaker impedance, as well as providing the voltage feed to the output valves. No biasing or other support components have been shown here - for more information on this, have a look at How Amplifiers Work. Another reference for valve stages is in the Valves section.

Figure 5.1 shows how this works. The primary winding acts in a manner that may surprise you at first, but it is quite in accordance with all the theory. The supply voltage shown is 500V, and we will assume that the valve can turn on hard enough to reduce this to zero alternately at each end of the winding. This is never the case in reality, because valves do not have a low enough internal impedance, but it makes the explanation simpler  .

.

Neither valve will draw appreciable current with no signal, and the amount drawn does not magnetise the core. The reason is simple - an equal amount of current is drawn through each section of the primary winding, but effectively in opposite directions. The magnetic field created by one half of the winding is cancelled by that from the second half, leaving a net steady state magnetic flux of zero.

When valve V1 turns on completely, the voltage at its end of the winding is reduced to zero, and the voltage at the anode of V2 is 1,000 volts. This must be the case, or the transformer theory is in tatters. The primary is operating as an 'auto-transformer'. Likewise, when V1 turns off and V2 turns on, the situation is reversed. You may well ask why 2 valves are needed at all? The voltage from one valve is quite capable of swinging the voltage from one extreme to the other, it would seem.

This is not the case. Since the valve can only turn on, it will only be able to supply current for 1/2 of the waveform. A Class-A push-pull design will normally have each valve carrying 1/2 of the maximum peak current required at idle, and the full peak current when turned on to the maximum before distortion (the other valve is turned off). In the case of a push-pull design, there is no core saturation because of the DC current (which cancels out as before), so although two valves are needed, the transformer will be smaller and will have very much better performance. Single-ended Class-A amps require a very large core with an air-gap to prevent saturation. This reduces the performance of the transformer dramatically, increases distortion and gives a poorer low frequency response because of the lower inductance. High frequencies can also be adversely affected, because the air-gap causes some of the magnetic flux to 'leak' out of the core. This is one cause of leakage inductance (covered in more detail in Section 2).

It is worth noting that the effective peak to peak swing across the entire transformer primary is 2,000V. When V1 is turned on completely, it has zero volts (for our example only) at the plate, and V2 has a plate voltage of 1,000V. V1 and V2 have exactly the same voltage peaks, but they are 180 degrees out of phase. The total voltage across the transformer is therefore the sum of the two voltages. From an AC perspective, the B+ supply line can be considered the same as zero volts (remember it will be bypassed with a large capacitance).

The RMS voltage (assuming a sinewave and ignoring losses) is easily calculated from the standard formula ...

5.1.1 Vp = Vp-p / 2

To obtain the peak value from peak to peak, then ...

5.1.2 Vrms = Vp / √2

To find the RMS value.

In this case, the peak to peak voltage is 2,000V, so peak is 1000V. The RMS value is 707V. In general, most valve designers prefer to keep the peak voltage well below 1kV, as this helps prevent flashover at the valve base and/or socket.

A transformer can influence the sound, and this may be good or bad, depending on the application and your expectations. Too little inductance means that the low-frequency response will be limited, and it will saturate if you try to get deep bass at any significant power. Leakage inductance reduces high-frequency response, so audio output transformers usually have interleaved windings - primary and secondary are separated into sections, usually with a combination of primary1, secondary1, primary2, secondary2 (etc.) with the last segment of the primary on the outside. This ensures very good inter-winding coupling and minimises leakage inductance.

Primary-secondary capacitance can affect the phase at high frequencies, limiting the amount of feedback that can be applied without phase compensation. At high frequencies, it can be difficult to provide enough feedback to ensure good linearity (and low output impedance), and this was a major impediment when trying to build valve amps to match the performance of transistor amps. Good valve output transformers are expensive, because the winding techniques are time-consuming, and that can add significant extra cost to the end-product.

Figure 5.2 shows the basic arrangement of a SET amplifier output stage. The full DC current must flow through the transformer primary, and as discussed above, an air-gap must be introduced into the core to prevent saturation. Because an air gap reduces the efficacy of the magnetic path, the core needs to be considerably larger than would otherwise be the case.

The core operates with only one polarity of flux, which varies with the signal. One might think that this alone would reduce distortion, since the flux never crosses the zero point, but this is not the case. It is still necessary for the flux to change direction, and the characteristics of magnetic materials indicate that the resistance to change (rather than the absolute polarity of the magnetic field) is the dominant factor. The valve (and transformer primary) must now carry a current equal to the peak AC current demanded by the load - subject to the transformation ratio, of course.

Maximum negative swing (valve turned on) will double this current, and it will be reduced to nearly zero as the valve turns off (positive swing). As the current is reduced below the average standing (quiescent) current, the voltage across the transformer increases in the opposite polarity - hence the fact that the plate voltage exceeds the supply voltage. This is one area where the transformer actually is an inductor, and circuit operation relies on the stored 'charge' of the inductor. The secondary winding simply couples the voltages to the load.

For the same power output, the valve in a single ended circuit must be considerably larger than that required for a push-pull circuit, because of the higher dissipation needed for the extra current. There are also many other issues with this arrangement - in particular high distortion and comparatively high output impedance.

Not the least of the issues is that the advantage of the additional voltage swing when using a centre tapped transformer is now gone, so the maximum RMS voltage that can be developed is 353V - a significant drop in primary AC voltage (again ignoring losses, it's exactly half). This means that the valve loading is higher for the same speaker impedance because the transformation ratio is smaller, so we get less power again.

Regular readers will be aware that I consider the 'SET' to be an abomination. The claimed advantages are mostly in the eye (or ear) of the beholder, and don't stand up to the slightest scrutiny.

Transformers are also used for 'line-level' low power applications, typically balanced microphone inputs and line output stages. A transformer is unsurpassed for real-world balanced circuits, as the input or output is truly floating, and requires no connection to earth. This means that common mode signals (i.e. any signal that is common to both signal leads) are almost completely rejected.

Figure 5.3 shows a transformer balanced input, converting to unbalanced. The signal is amplified, and sent to the output transformer for distribution as a balanced signal again. The 'amplifier' will typically be a mixing console, and will take mic or line level signals as the input (having run from the stage to the mixing area), and the final mixed output is sent back to the stage for the main (Front of House) public address amplifiers and speakers. There may be in excess of 100 metres of cable from the microphone to the mixer and back to the main amps, and barely any noise will be picked up in the process.

The telephone system used to be completely dependent on transformers to feed the signal from the exchange (or Central Office in the US) to the customer premises equipment (CPE). The phone switch used in offices, (PABX - Private Automatic Branch Exchange, or PBX for the US) equipment still uses transformers for nearly all incoming circuits whether analogue or digital.

The principle is exactly the same as for the audio application shown above, except that for telephone circuits there is usually a DC voltage present to power the CPE (in the case of a home telephone) and to provide some basic signalling. Modern PABX circuits use ferrite cored transformers, with DC isolation circuitry to ensure that no DC flows in the transformer windings, as this degrades the performance in the same way as with the output transformer for a SET power amplifier. (Note that many subscriber circuits are now operated via purpose-built ICs that eliminate the transformer.)

Audio applications for transformers in balanced circuits came from the telecommunications industry where the concepts were first thought of. A telephone line may be 4km or more in length, and is not shielded, so a method of eliminating hum and noise was essential. Today, there are tens (hundreds?) of millions of transformers in use for Ethernet LAN connections, and RJ45 sockets are available with the transformers built-in.

Safety is a major consideration for any power transformer (and in the case of telecommunications, the isolating transformers), and electrical contact between primary and secondary must not be allowed under any realistic fault condition. All countries have safety standards that apply to transformers where electrical isolation is important, and if in any doubt about the safety of a transformer for a particular purpose, make sure that you verify that the transformer complies with the relevant standard(s). It is well beyond the scope of this article to cover all the possibilities of standards and compliance issues, so I shall leave that to you - and your supplier.

Many power transformers are fitted with an internal 'once only' thermal fuse that will become open circuit in the event that a preset temperature is exceeded. This temperature is chosen to be the maximum safe temperature of the windings before the insulation melts or breaks down, so in the event of a fault, the thermal fuse will open before the insulation is damaged and the component becomes potentially dangerous. It also helps to prevent the risk of fire (and no, this is not intended to be humorous - a friend of mine had his house burned to the ground because of a faulty power transformer in a video recorder - as determined by the fire investigators. True story!). See Figure 6.1 (below) as an example of how bad things can get if the transformer is not protected.

Once the thermal fuse opens, the transformer must be discarded, as it is usually not possible to gain access to the fuse for replacement. This is not as silly as it may sound, since the thermal degradation of the overheated insulation cannot be predicted, and the transformer may be unsafe if it were still able to be used.

There are transformers that are designed to be 'inherently safe', and these usually have the windings on separate sections of the core, not in physical contact with each other. If the core is connected to the electrical safety earth (which is usually a requirement), no method of failure (including a complete meltdown) in the primary will allow mains voltage to appear at the secondary. Side by side windings are the next safest, and although primary and secondary are on the same bobbin, the material used is selected to withstand high temperatures and will maintain separation of the windings. Toroidal cores and other concentrically wound transformers are the least safe, since the only separation between primary and secondary is a rather thin layer of insulation. This is one of the reasons that thermal fuses are often used with toroids. Note that any transformer classified as 'inherently safe' must usually meet very strict approval conditions in most countries.

Figure 6.1 shows a transformer I removed from a repair job. It is a complete meltdown, and the remains of the plastic bobbin can be seen quite clearly. In any circuit, it is extremely important to protect the user from coming into contact with the mains should this happen. In this case, the bobbin had melted away from the windings, dribbled on the base of the equipment, and generally made a big mess. Despite all this, there was no electrical connection between primary and secondary or the laminations. This was a well made transformer (it failed due to gross continuous overload, not any failure in the transformer itself).

Proper safety earthing is the only real way to ensure that a transformer that fails catastrophically (such as that shown) does not cause the chassis to become live - not all transformers are created equal when safety is concerned. Correct fusing will ensure that the fuse blows - hopefully before the electrical safety is compromised. A thermal fuse would have prevented the situation from becoming as bad as shown, but the transformer would have been just as dead.

Transformers make noise. This is not only the electrical noise that is created by the nasty current waveform through the windings, diodes and into the filter capacitors, but actual audible noise. One source is winding vibration, due to the wire moving because of the magnetic field and the current flowing through the conductors. This is to be avoided at all costs, since constant vibration will eventually wear away the insulation, the windings will short circuit, and the transformer is ruined. Fortunately, this is rather unusual, but it can (and does) happen on occasion.

Most of the noise is from the laminations or other core material interacting with the windings due to the magnetic field. There's another effect called magnetostriction, and happens to a greater or lesser degree with all magnetic materials, but for most small transformers (2kVA or less) it's not a problem. A stethoscope will verify the source of the noise, and there is little or nothing that will stop it, other than vacuum impregnation (maybe). A resilient mounting will stop most of the noise from being acoustically amplified by the chassis, and generally the noise will be worse at no load. In some cases, a transformer may have been designed for 60Hz, but is used at 50Hz. In this case, the flux density will probably exceed the maximum allowable for the core (which will saturate), and the transformer will get much hotter than it should, and will almost certainly be a lot noisier as well. Toroidal transformers will generally be much quieter than EI laminated (i.e. conventional) types.

Most (all?) transformers designed specifically for 60Hz will eventually fail with 50Hz mains, due to overheating. The reverse is not true, and 50Hz transformers can be operated quite safely on 60Hz.

Another problem with E-I laminations is that they may not have been fastened together well enough, and this allows the outer laminations in particular to vibrate. Better quality conventional transformers will commonly be impregnated with varnish (sometimes under vacuum) and baked in a moderate oven until tender .... oops, I mean until the varnish is completely dry. This binds the laminations and windings together, preventing noise, and also making the transformer more resistant to damage by water or other contaminants, and/ or under conditions of high humidity (such as in the tropics).

Click on any of the above to see the remaining sections in this series. As I am sure you have noticed, transformers are not so simple after all.

These references are common to both sections of the article, although most only apply to Section 2. Countless different Web pages were researched during the compilation of these articles, and although some were interesting, the majority were of minimal use. Of those who I actually remember (a daunting task in itself, considering the sheer amount of searching I had to do), I must thank the following Web pages (in alphabetical order) ...

Although not used as a reference, I recommend the article The History of the Transformer. It's not technical, but does give some insight into the development of transformers as we know them.

In addition, I have used various other references, but notably (in order of usefulness) ...

The following (slightly edited) definitions are from Units of Measurement

Units of Measurement site copyright by Russ Rowlett and University of North Carolina at Chapel Hill.

(Definitions used with permission from the author.)

Tesla (T) - flux density (or field intensity) for magnetic fields (also called the magnetic induction). The intensity of a magnetic field can be measured by placing a current-carrying conductor in the field. The magnetic field exerts a force on the conductor which depends on the amount of the current and the length of the conductor. One Tesla is defined as the field intensity generating one Newton of force per ampere of current per meter of conductor. Equivalently, one Tesla represents a magnetic flux density of one Weber per square meter of area. A field of one Tesla is quite strong: the strongest fields available in laboratories are about 20 Teslas, and the Earth's magnetic flux density at its surface, is about 50 microteslas (µT). One Tesla equals 10,000 gauss. The Tesla, defined in 1958, is named after Nikola Tesla (1856-1943), whose work in electromagnetic induction led to the first practical generators and motors using alternating current (much to the annoyance of Edison, who claimed DC was 'safer').

Weber (Wb) - magnetic flux. 'Flux' is the rate (per unit of time) in which something crosses a surface perpendicular to the flow. In the case of a magnetic field, then the magnetic flux across a perpendicular surface is the product of the magnetic flux density, in Teslas, and the surface area, in square metres. If a varying magnetic field passes perpendicularly through a circular loop of conducting material (one turn), the variation in the field induces a electric potential in the loop. If the flux is changing at a uniform rate of one Weber per second, the induced potential is one volt. This means that numerically the flux in webers is equal to the potential, in volts, that would be created by collapsing the field uniformly to zero in one second. One Weber is the flux induced in this way by a current varying at the uniform rate of one ampere per second. The unit honours the German physicist Wilhelm Eduard Weber (1804-1891), one of the early researchers of magnetism.

Main Index

Main Index

Articles Index

Articles Index