|

| Elliott Sound Products | Australian (Worldwide?) Ban on Incandescent Lamps |

Main Index

Main Index

Articles Index

Articles Index

PLEASE NOTE: My apologies for the length of this article, but this has turned into something of a horror story. Only a short while ago, I thought that the power factor issue was most important, then that a vast number of enclosed light fittings (probably hundreds of millions worldwide) cannot be used with CFLs was critical. Now, it turns out that dimmers are a far bigger issue than first imagined. What happens in houses where dimmers are fitted? These must be removed completely, not simply set to maximum and left there. Who's going to pay to have millions of dimmers worldwide removed by electricians? You, the homeowner - that's who.

PLEASE NOTE: My apologies for the length of this article, but this has turned into something of a horror story. Only a short while ago, I thought that the power factor issue was most important, then that a vast number of enclosed light fittings (probably hundreds of millions worldwide) cannot be used with CFLs was critical. Now, it turns out that dimmers are a far bigger issue than first imagined. What happens in houses where dimmers are fitted? These must be removed completely, not simply set to maximum and left there. Who's going to pay to have millions of dimmers worldwide removed by electricians? You, the homeowner - that's who.

Power factor is still very important ... while you only pay for the actual energy used (as shown on the packaging), power companies have to provide the full voltage and current (also shown on many packages and/or other literature). The relatively poor power factor increases distribution losses and therefore the cost of getting electricity to your house.

Now, we also have the European Union (EU) singing the same silly song. It was recently announced that the 490 million citizens of the 27 member states will be expected to switch to energy-efficient bulbs after a summit of EU leaders yesterday told the European Commission to "rapidly submit proposals" to that effect. I wonder just how much research was done before this piece of lunacy was announced? None, perhaps?

Speaking of the EU, these mental giants have recently decided to ban mercury altogether. Apart from the considerable annoyance to people who use it for manometers, barometers, certain antique clocks, etc., the ban is inconsistent. While they will probably eliminate a few kilograms of mercury from those who would use it responsibly, there will be hundreds or perhaps thousands of kilograms (in CFLs and conventional fluorescent lamps) in the hands of the general public. Most will end up in landfill unless there is a very comprehensive education campaign for the householders throughout the EU and elsewhere. So far, there appears to be little or no effort anywhere to ensure that the public are made fully aware of the risks involved. As of early 2010, there are still people who remain blissfully unaware that CFLs contain mercury!

Nothing in this article is conjecture or CFL bashing (I like CFLs used sensibly, and have (had) installed them wherever possible in my home and workshop), merely simple facts that a great many people have overlooked. The reasons are described below (yes, it's mostly technical), and for those who want to know more about power factor, the use of CFLs in existing luminaires, or any of the other factors involved, please read on ...

(External links in this article are for information only, and do not necessarily reflect the opinions of the author of this page.)

Please Note: Since this article was written, I have made the transition to LED lighting almost exclusively. All linear fluorescent lamps have been changed out for LED 'tube' lights, and there are now only three CFLs and not even one 'high efficiency' halogen incandescent lamp in my house and workshop. The Australian 'phase out' of incandescent lamps appears to have stalled, and products that were slated for exclusion from sale are still available. The selection of lighting from supermarkets now includes several LED types, not so many CFLs, and quite a few halogen 'bulbs'. While these have higher luminous efficacy than standard incandescent lamps, they don't come close to LEDs, which are now commonly providing better than 100 lumens/ Watt (including the power supply losses).

However, little has changed regarding suitable luminaries, and it's still challenging to find fittings that have adequate ventilation. The public's understanding of thermal performance hasn't improved, and many LED 'bulbs' run far too hot for the good of the internal electronics. Dimming continues to be a problem with all forms of electronic lighting, because home users in particular don't understand why legacy dimmers are unsuited to electronic lighting power supplies. Please see the articles on dimmers for detailed information ...

Lighting Dimmers

Lighting Dimmers - Part 2

Dimmers And LEDs

As described in the above articles, conventional leading-edge dimmers (by far the most common) are completely unsuitable for use with any electronic load. Trailing-edge dimmers are much kinder to the components in the lamp, but whether they work properly is a lottery. The only dimmer that provides predictable performance and causes minimum stress is a 3-wire trailing edge type. These are not common, and most home wiring is done in such a way that some re-wiring is needed so that a 3=wire dimmer can be used - if you can find one!.

Project 157 is (at the time of writing) the only design on the Net for a complete 3-wire trailing edge dimmer. It's been built and tested, and works with any dimmable LED or CF lamp, as well as incandescent lamps and even some non-dimmable electronic lamps (with varying degrees of success, depending on the design of the lamp's power supply (aka 'ballast')

While LED lighting is currently the best choice for efficacy and longevity, not all problems are 'solved'. In particular, proper ventilated housings are essential to ensure that the temperature is kept as low as possible. Budget LED lights can't be expected to last very long, because the makers will skimp on all essential parts, especially the heatsink. LED 'replacements' for 12V halogen downlights have been a disaster, because the form factor of the standard MR16 downlight lamp is too small to allow a decent heatsink. Several have been made with tiny fans inside, but that's not a solution, it's a band-aid.

As of 2020, many of the problems have gone away, since CFLs are becoming less common, some outlets don't even sell them any more, and LED lighting has taken over for the most part. As a result, many of the problems with CFLs described below are no longer relevant. Luminaire ventilation (for fittings with replaceable 'bulbs') still hasn't been addressed, but the LED lamps you can get today seem to be very reliable for the most part. There will always be early failures ('infant mortality' as it's known in industry), but most will happen during the warranty period.

My house and workshop are now illuminated exclusively with LEDs, either tubes or 'bulbs'. I'm hard-pressed to recall the last time I had to change one due to failure, but the odd few have been swapped around to get the balance right in a couple of rooms. The energy savings are easily calculated, and forgetting to turn a light off occasionally doesn't make any discernable difference to my total energy use. I haven't removed the earlier information because it may still be interesting, even though most of the issues have gone away with the plunge in use of CFL lamps.

Several sections have been moved to separate sub-pages to try to reduce the size of this article. For the links to work properly, you must have Javascript enabled on your browser. The sub-pages use script to create popup windows with a 'close' button. You can open the files in a new window by right-clicking the link if you prefer. Because you might easily miss some of the sub-sections, there is an index of these extra pages below. These links do not rely on Javascript.

Index of Sub-Pages

It is now illegal for anyone to import conventional incandescent lamps (light bulbs) into Australia, except for a few specialty types. In most shops, there isn't an incandescent lamp to be seen, although some have small fancy types as might be used in some specialty chandeliers or similar fittings. Insanely, halogen downlights are still readily available because they pass the MEPS (Minimum Energy Performance Standards) criteria ... just. They have also caused a number of house fires because ceiling insulation was too close to the fitting (there are special clearance requirements for downlights and any type of insulation).

So far, it's fairly safe to say that few households will have seen a dramatic reduction in their power bills, and the governments (local, state and federal) have remained stoically silent regarding any form of mandatory recycling scheme to prevent a build-up of mercury in land fill waste disposal facilities. The Copenhagen conference came and went with no firm commitment by anyone.

No-one seems to have noticed that it is immaterial if global warming/ climate change is man-made or not. The fact is that we cannot continue the way we are because the resources we are depleting will eventually be gone. It won't have a major impact on those who are around now, but future generations will have good reason to curse us to eternal damnation for the massive waste of valuable resources over the last hundred years or so. And rightly so - what we have done (and are still doing) is nothing short of shameful. Governments are more interested in being seen to be doing something (large, highly visible projects) than actually doing anything ... like switching off unused lights in government buildings at night.

Meanwhile, the cry to ban the humble incandescent lamp (also known as GS - general service or GLS - General Lighting Service) may not seem like such a bad idea at first glance, but there are a number of issues that have not been addressed (or even thought about, based on what has been heard so far). Incandescent lamps are inefficient, typically over 95% of all energy consumed is converted into heat - not light. By comparison, the CFL (compact fluorescent lamp) has a dramatically higher efficiency, although it falls well short of a full sized (18W or 36W) standard fluorescent tube. The latest tube-type fluorescent lamp is the T6 - thinner than the traditional T8 we mostly use, and can only be used with an electronic ballast. These have greater efficiency (more lumens/Watt) than all earlier fluorescent tubes, and use a ballast that doesn't get thrown away with the tube.

Many people have tried CFLs in any number of locations, but they are not always liked because of their colour rendition (many colours look wrong under all forms of fluorescent lighting), and because they are considered by many to be rather ugly. These dislikes are not necessarily major issues of course, although there are many users who would disagree.

Lighting is actually a very complex topic, and although it seems pretty simple on the surface, there are many factors to consider that proposed legislation will utterly fail to address. Just look at the European RoHS (restriction of hazardous substances) legislation as an example of how wrong things can get when governments become involved in things they don't understand.

This article is not intended to be a complete and final discussion - because lighting is so complex, I am bound to miss things, and I can only rely on the information I can get my hands on. There is undoubtedly a great deal that I won't find. Hopefully though, this article may get a few people thinking of the long term implications of the proposed ban (which is almost completely meaningless in real terms).

As a side issue, although I have (mostly) used the term 'efficiency' in this article, this is actually relatively meaningless for lights. The correct term is luminous efficacy, usually expressed in lumens / Watt. While not strictly accurate, comparing the relative efficiency of different light sources does make it easier to comprehend - few people outside of the lighting industry will really have a proper grasp of the concept of luminous efficacy, so I have elected to keep the term 'efficiency' in the interests of making the article as easy to understand as possible.

The nice people at LV Lighting (now gone) saw this article some time ago, and sent me a LED lamp to trial. The lamp is excellent, and I would have no hesitation recommending these to anyone. The colour temperature is good, and the lamp doesn't get excessively hot in use. This is not to say that it runs cool - it doesn't. The front bezel is a heatsink, and this gets quite hot after it's been on for a while. Now over three years later, it's just as good as when new (it gets used for up to 4 hours a day), and I now have quite a few LED lights around the house too.

As with CFLs, the current crop of LED lamps need good ventilation, because the electronics (and LEDs) must always be kept cool in order to obtain maximum life. With a minimum rated life of 20,000 hours (up to 50,000 hours is also claimed on the pack, 80,000 to 100,000 hours elsewhere on the Net), no CFL can even come close. There's also no mercury involved, so disposal is less of an issue. While it pains me to see perfectly good electronic parts being thrown away, reality indicates that it will happen whether I like it or not - at least there's no risk of contaminated landfill. Wasting perfectly good aluminium (used as the heatsink) is cause for some concern though, because aluminium production is extremely energy-intensive.

LED PAR20 Lamp

The lamp I was sent is a PAR20 style. PAR (Parabolic Aluminised Reflector) lamp sizes are based on the number of units of 1/8 inch that indicates the diameter, so this lamp is 2½ inches in diameter (or 63mm in real measurements). The metal section around the front is the heatsink for the LEDs, and given that the lamp's rating is only 8W, it dissipates a surprising amount of heat. The main difference between this and a CFL is that the heat is predominantly external, and the electronics are not subjected to the main heat source ... with CFLs, the source of most heat is the tube filaments, and these are inside the tiny housing that holds all the electronics. The light source is 6 x 1.3W Cree XRE LEDs, and the LEDs are powered by a fairly conventional (but very nicely built) switchmode power supply (yes, I've had the lamp apart).

There seems little doubt that this is the way of the future. By comparison, the CFL that's presently installed in the same lamp standard comes a rather poor second place, even though it's also rated at 8W. At around $50-70 each, the biggest disadvantage with the LED lamps is their cost, however that can be expected to fall as production and demand increase. Even at the current price, the LED lamp is actually a better (although not yet cheaper) choice than a CFL. While it may not appear so at first glance, the LED based lamps can be expected to outlast up to eight CFLs, but they suffer few of the disadvantages.

| Lamp Type | Power | Life | Cost | Total Cost | Per Hour |

| Incandescent | 75W | 1,000 Hours | $0.50 | $11.75 | 1.175 Cents |

| CFL | 8W | 10,000 Hours | $4.00 | $16.00 | 0.16 Cents |

| LED | 8W | 50,000 Hours | $60.00 | $120.00 | 0.24 Cents |

Total cost is purchase price plus electricity cost based on $0.15 / kWh for the total rated hours of operation. Per hour cost is total cost divided by rated life in hours. Should a CFL or LED lamp last less than the rated number of hours, the cost per hour will increase. It should be noted that the actual cost of electricity has risen dramatically since this article was written, but I have not updated every calculation for obvious reasons.

While the LED lamp appears more expensive, remember that unlike the CFL, it is immune from premature failure due to switching cycles and does not need to be on for up to 5 minutes while you wait for the light output to reach the normal level. LED lamps are also not bothered by low temperatures, so extremely low light output (or none at all if it's cold enough) isn't an issue. As the price falls, expect the total cost to fall significantly. Also, note that only a 'mid priced' CFL was used for this comparison. A premium brand may actually last as long as claimed, but will be more expensive than shown above. So far, I seriously doubt that any CFL I've used has lasted (or will last) the rated number of hours.

Overall, there is good reason to expect that CFLs are merely an interim solution. While they are presently very cheap (unrealistically so in my view), the ever-increasing demands from environmental groups to force proper recycling will ultimately drive up the cost. Meanwhile, the LED lamps will get cheaper as production methods and technology improve their cost effectiveness. In Europe, the WEEE directive will apply regardless, but recycling LED lamps will be far cheaper than recycling CFLs, because there is no requirement for capturing and storing mercury and mercury vapour.

However, even LED lamps fail to address all the issues. Just like CFLs, they can't be used in very hot environments (such as oven lights), and they can't be used in completely sealed luminaires as are required for outdoor or hazardous/explosive atmosphere lighting. However, LEDs are so easy to use (no fragile glass or high voltages) that these problems can be solved by producing specialty lamps with provision for external heatsinks (for example). These are now available from many sources, as streetlights, floodlights for home and industry, and many other specialised applications.

Speaking of heat, there's a bold warning on the pack that the LED lamp must not be used in sealed light fittings. Just like CFLs, the electronics don't take kindly to being overheated, and doing so will cause premature failure. Although I didn't test it, I expect that this lamp would also be completely unsuitable for use with a dimmer (even turned to the maximum setting). I didn't run a test because of the fact that the SMPS (switchmode power supply) is rated for use with any voltage from 100 to 260V - so reducing the voltage with a dimmer will have little or no effect.

Power factor (see below for more on this topic) is still an issue. The SMPS used in low cost LED lamps has around the same power factor as typical CFLs, so the peak current drawn will be of a similar order. This means that mains waveform distortion remains a problem, but this can be solved. Nothing will happen until supply companies start charging residential customers for Volt-Amps (VA) used, rather than power. It is worth noting that quite a few recent LED lamps are using active PFC (power factor correction), which reduces the high peak current and reduces mains harmonics. A typical 9W LED lamp with active PFC will only draw around 10VA - a power factor of 0.9

Because LEDs are low voltage devices, the SMPS used to drive them is very easily made to have complete isolation to double-insulated standards. The LEDs and their heatsink can be accessible without fear of electric shock, making the construction of LED based lamps far more flexible that can ever be achieved with CFLs or even traditional incandescent lamps.

Many people would have seen the story circulating the Net (some time ago) about a woman in Maine (US) who broke a CFL in her daughter's bedroom, and was quoted $2,000 to clean up the mercury. This is what happens when bureaucrats become involved in things they don't understand (like lighting for example). This story is scare-mongering at its lowest. While I have no doubt that the figure is correct, it would be plain stupid to involve bureaucrats in something as trivial as a broken CFL.

Yes, mercury is a potent neurotoxin, but metallic mercury is relatively safe. The real danger comes from the vapour and various salts and compounds (particularly methyl mercury as may easily be created in landfill for example) ... not from 5mg of mercury buried in the carpet. Having said that, I'm not sure I'd be happy letting a small child play on the floor where any fluorescent lamp had been broken. Kids have enough things to cause them damage or injury without adding tiny glass shards and mercury to all the other concerns.

Perhaps governments and CFL manufacturers could provide the necessary cleanup procedures that should be undertaken to ensure that the area is reasonably safe after 'contamination'. At present, you will find a great many conflicting opinions as how best to clean up after a breakage, but almost no usable information about the possible risk from the mercury itself. For myself, I'd probably not be at all concerned, but my kids are grown up and have their own homes. With small children around, I'd want to know with reasonable certainty that a recommended cleanup process would make the area safe enough for them to play on.

He has visited Chinese factories where CFLs are made, and tells me that mercury spillage is common during the manufacturing process, and that the workers have zero protective clothing, masks or anything else to safeguard their health. This means (as many could easily have predicted) that while our environment may benefit by using CFLs, the Chinese environment and factory workers most certainly do not.

In years to come, there will be massive clean-up bills to decontaminate factories and surrounding areas where CFLs were made, and with spillages happening regularly the long term health of the workers is certainly at risk. This is not confined to just one factory either - the same thing has been seen in several facilities visited by my corespondent.

It seems that no-one cares (or wants to care) about things they cannot see. Until governments world-wide can ensure that proper safeguards and decent safe working conditions are a requirement for 'environmentally friendly' products, these products should simply be banned from sale.

It is also well known that Chinese test houses will cheerfully fake test results that are required information for the certification of products in the countries where they are sold (Australian Standards, UL, CSA, VDE, etc., etc.). On Australian TV only recently, it was shown that Chinese made air conditioners (with full test documentation) were found to fail the mandatory Australian 'Minimum Energy Performance' criteria - despite Chinese lab test results that clearly showed that it passed. Does anyone really think that all products that come from China will match the test results that come from Chinese laboratories? I certainly hope not, because one would have to be extremely naive to believe that these overseas labs will be as rigorous and thorough as those in the target importing country.

There is one thing that could have been done, and it could easily have been implemented. Needless to say, nothing was done that was even remotely sensible. A surcharge (indexed each year) on all lamps below a given luminous efficacy can be used to finance a carbon 'offset' programme, with all money collected devoted 100% to planting trees or other viable efforts towards reducing our 'carbon footprint'. The extra (and increasing) cost of low efficiency lamps of all types will encourage people to use CFLs (or other high efficiency lighting) wherever it is sensible to do so, and will help to ensure that as light fittings are replaced by new ones (during remodelling or because of breakage etc.), the replacements will be designed to be CFL friendly. Some people may even want to use tinted glass to recover the 'warm' glow they are used to. We also get more trees, something that many areas throughout the world have depleted to depressingly low and aesthetically unappealing numbers.

Such an approach causes the minimum disruption, minimises waste from CFLs that fail prematurely because of inappropriate light fittings, and is a far more sensible approach than imposition of a blanket ban that will cause many people much grief. The surcharge can be altered as CFL (or better still, LED) technology improves (allowing better dimming ability for example), and eventually, only a few lamps in most households will use incandescent globes because CFLs cannot be used (see the rest of the article to find out why CFLs cannot be used in some areas).

This approach is sensible (one good reason for government avoidance), and over a period of only a few years has the potential to exceed the (claimed) benefits of an outright ban by an order of magnitude. Such a programme will have real and immediate results - something that is suspect at best (and possibly substantially negative) with the present plans to simply ban incandescent lamps.

Eventually (my guess is within 5 years, but see above if you missed it), LED lighting will have improved so much that the whole mess may be resolved anyway. However, even LED (light emitting diode) lamps cannot be used at high temperatures (such as oven lights), so the incandescent lamp will never really die. They do allow full dimming ability though, but this capability needs to be included in the circuitry. There are already some LED based lamps available that are not just a usable alternative - one I was given is excellent, and I'm highly impressed.

Consider too that lighting is normally used at night (this will surprise no-one). In Australia, electricity companies offer very cheap rates at night, because they have Megawatts of capacity just spinning around with not much to do (known as spinning reserve). The lights that we use domestically offer very little loading, so where's the saving in greenhouse gases? The alternators aren't just shut down, because it takes up to 12 hours to get a large coal-fired alternator on-line. Incentives are offered to get people to use the spare capacity at night for storage hot water systems (for example). This isn't to say that electricity should be squandered, but merely to put it into some perspective. (Note that the off-peak system does not operate in many parts of the world.)

Wherever possible, sensible and safe, I highly recommend using CFLs. You will reduce your power bill, and you will save electricity. If you are mindful of the limitations, there are real benefits and these should be embraced. As noted in several places, I now use LED lamps everywhere I can, both in the house and my workshop. None of my main lighting uses conventional fluorescent lamps, all are now fitted with LED tubes, which provide the maximum efficiency for domestic lighting. There are still a couple of CFLs in use though.

If the powers that be (wherever in the world they are) are serious, then the obvious answer to working out if there are any genuinely worthwhile benefits to a ban on incandescent lamps is fairly simple. Conduct a trial. Select a small town, and choose 50% of randomly selected dwellings to continue the way they are already, and get the other 50% to use CFLs exclusively. No modifications to light fittings, no changes to anything other than the type of lamps used.

With careful monitoring of both sets for lamp failures, total energy usage (electricity, gas, heating oil, etc.) and overall satisfaction or otherwise, a realistic set of statistics can then be developed to show exactly what the outcome of a wholesale ban would achieve. This is real science, using a controlled test environment to gather information that can be expected to be reasonably representative of the benefits to the area tested and anywhere else that has similar climate. Data may be extrapolated to determine a realistic potential outcome for other localities.

While businesses may be included, many (if not most) will be found to be using conventional tube fluorescent lamps, because of the necessity for good lighting in most areas of business (cinemas, nightclubs and many restaurants being notable exceptions).

Such a trial needs to be run for 1 year, and at the end, people will have real data from real homes in a realistic environment. This is a far cry from the situation at present, where we have a few zealots sprouting figures that either make no sense, are often obviously false, or are simply the same as the (often wrong) figures sprouted by other zealots. I'm getting rather fed up with some of the claims, as they seem to be based entirely on fantasy. One I saw claimed that "Changing one incandescent lamp for a CFL will save £9 in one year, or £100 over the life of the lamp." (or along those lines - I can't find the quote this time around). Based on those figures, the lamp has to last for over 11 years - a fairly unlikely scenario. In common with many such claims, the lamp power wasn't mentioned, what it replaced wasn't mentioned, and no supporting data was mentioned either. In other words, the figures claimed have no substance at all - pure horse-feathers.

Because most of this section seemed to create more distraction than benefit, it has been removed. However, some sections are still worthy of inclusion.

One thing I have seen in countless forum sites, blogs and other areas is especially disconcerting. Some people seem to have a completely black and white approach to many things related to CFLs. There is often a complete refusal to accept that anyone else's experience is valid, because it either disagrees with published data, the experience of others, or for reasons unknown.

Some people may delude themselves, albeit unintentionally. They may grossly overestimate the life of the lamp ("Well, it says on the package that it lasts 10,000 hours, so it must have done.") - in fact, the lamp may have lasted a great deal less than its rated life. In reality - unless you keep a log - how does anyone really know how many hours of use any lamp in their house has actually lasted if it's switched on and off? We don't. We make estimates, based on what seems to be the case, tempered by expectations and boosted by advertising (or other) promotions. After a year or more, we are very unlikely to remember when it was changed last.

The same 'logic' has been used to proclaim that CFLs work "just fine" with motion detectors and/or timers. Others have claimed that they don't work at all. Neither is right ... see below for more information.

Similar arguments are applied to colour rendering index, the 'human friendliness' of the light and almost any other area that pertains to the debate. This topic - like any other of importance - needs to be examined dispassionately. The points laid out below are a combination of measured data, simple and demonstrable facts, and information from manufacturers and lighting professionals. Passion and personal preference carry little weight (either for compact fluorescent or incandescent lamps) in what follows here. This article has its basis in facts, not any personal vendetta against one technology or the other.

You can find more information at any number of sites on the Net, and if anyone doubts that there really are problems, then a web search should disabuse you of such notions pretty quickly. Make sure that the information has basis in reality - anyone who simply raves or rants (for or against) with no technical information is not a source of useful information.

As noted above, the term 'efficiency' is fairly meaningless for lighting. Luminous efficacy is a measure of how much light one obtains for a given power input. If one uses the maximum theoretical luminous efficacy figure (683 lumens / Watt) as a starting point, then an approximate efficiency figure can be worked out easily enough. The following table is condensed from that shown on Wikipedia [1]. Click here for the full article.

| Lamp Type | Power | Luminous Efficacy (lm/W) | Efficiency ¹ |

| Tungsten incandescent | 40W | 12.6 | 1.9% |

| Tungsten incandescent | 100W | 17.5 | 2.6% |

| Quartz halogen | n/a | 24 | 3.5% |

| Fluorescent (compact) | 5W - 24W | 45 - 60 | 6.6% - 8.8% |

| Fluorescent tube (T8 120cm / 4 ft) | 36W | 93 (max, typical) | 14% (max, typical) |

| Fluorescent tube (T5 115cm / 45 in) | 28W | 104 | 15.2% |

| LED (various formats) | n/a | 60 - 110 | 7.5% - 15.5% (approx) |

| Xenon arc lamp | n/a | 30 - 50 (typical) | 4.4% - 7.3% |

| High pressure sodium | n/a | 150 | 22% |

| Low pressure sodium | n/a | 183 - 200 | 27% - 29% |

| Ideal white light source | 242.5 | 35.5% | |

| Theoretical maximum | 683.002 | 100% | |

¹ - The term 'efficiency' is actually fairly meaningless. This is a measure of the 'overall luminous efficiency', and is included as a comparative figure only, calculated such that the maximum possible efficiency is 100% | |||

Where the power rating is indicated as 'n/a', this indicates that luminous efficacy is not affected significantly by the power rating. Many lamps become more efficient as their power rating increases, with incandescent and CFLs being good examples. While it is easy enough to imagine that this will be so with traditional lamps, it is a little more subtle with a CFL. Essentially, the electronic circuitry has limited efficiency, and will consume some current just to operate. For low power lamps, this basic operating current is a higher percentage of the overall, so the effective efficiency of the assembly is reduced accordingly.

As becomes readily apparent from the above, even a CFL with a reasonably high efficiency still discards over 90% of the energy supplied as heat. While the total input energy is less than for an equivalent incandescent lamp, the maximum temperature to which the lamp may be subjected is also a great deal lower because of the electronic components. This means that CFLs can only be used successfully with well ventilated fittings (see below for more information on this topic).

With all lighting types, something that is of particular interest to HVAC (heating, ventilation & air-conditioning) engineers is the total heat load from lamps. In general, this is actually the full power rating. All light (whether visible or not) that is emitted eventually lands on surfaces and is converted to heat. After all, light is energy, and that energy is simply converted to heat when the light is absorbed. More efficient lighting means less total power for the same light output, so overall luminous efficacy is the only really important factor to consider.

LEDs are improving all the time, and prices are coming down. The chips themselves are commonly better than 100 lumens/ watt, and the reductions for a complete system are largely due to the power supply. High quality supplies will obviously cost more than those that will just do the job, and the sensible approach is to keep the LED array and power supply separate. This allows either the LED array or power supply to be replaced independently. Other than commercial lighting where this is common, most consumers just want something that looks like the old style 'bulb' they are used to seeing. While many of these are now a viable alternative to other lighting, they are still a compromise.

LED lighting is covered in more detail in several of the other articles on the ESP site. See the Lamps & Energy Index for more details.

Interestingly, there is a 'standard' table of equivalence (power Point Presentation) for CFLs vs. incandescent lamps (supposedly accepted worldwide). It is interesting in that the figures claimed are much less than the above table would lead one to believe. The table is shown below. For example, a 100W incandescent is shown as having an output of 1,246 lumens, yet the above table indicates that it should be 1,800 lumens, and a 40W incandescent should provide 504 lumens, yet is downgraded to 386 lumens. The problem is that no-one seems to disagree that 17.5 lm/W is reasonable for a 100W incandescent lamp, so how did it get changed? I find this kind of deception very annoying (to put it mildly). The US Energy Star programme has a different standard, as well as a set of standards that few CF lamps will meet (of those sold in Australia, at least). See ENERGY STAR (Criteria, Reference Standards and Required Documentation for GU-24 Based Integrated Lamps) to read the requirements in full. Their equivalence table is more in line with reality than the previous reference, but other Australian government departments (see below) and CFL manufacturers seem to prefer the other.

One maker may claim their 13W CFL to be the equal of a 60W incandescent, another says their 13W CFL is equal to 75W - the lack of any standardisation allows huge leeway for makers and advertisers (as well as politicians). The consumer loses out by getting less light than expected, tarnishing their opinion of CFLs in general.

| Power (W) | 150 | 100 | 75 | 60 | 40 | 25 |

| Lumens | 2009 | 1246 | 874 | 660 | 386 | 214 |

| Lumens (Energy Star) | 2600 | 1600 | 1100 | 800 | 450 | 250 |

So who decided on the 'standard' equivalence table? Why are the figures so different from what we should expect? I would be very interested to know who decided to downgrade a 100W lamp from 17.5 lm/W to 12.46 lm/W - could it have been the CFL manufacturers perchance? This is but one of many anomalies that you'll come across when you start to look into the subject carefully. Even the Energy Star ratings have been criticised as too low! Luminous efficacy does increase with reduced operating voltage (120V vs. 230V for example), and this is because the filament is thicker and stronger and can be run at a higher temperature (12V halogen downlights are a good example).

Many people have complained that CFLs that supposedly replace various incandescent lamps are not as bright as expected (these gripes can be found all over the Net). Remember too that CFLs lose light output as they age - the effect is sometimes very noticeable, and I've replaced several that were too dim to be useful, but had no more than around 500-1000 hours of use.

A couple of documents from Australian government groups (see 'EnergyAllStars' and 'National Appliance and Equipment Energy Efficiency Program' both use the table shown above. Based on any tests that anyone might want to perform themselves, these figures inflate the light output from CFLs compared to incandescent lamps. Most people who have used a CFL know that the light output is often not equivalent to the claimed 'equal' incandescent lamp. There are (supposedly) perfectly good reasons for the discrepancies, but so far I remain unconvinced.

Most industry websites claim that the CFL is simply an equivalent product to the GLS (General Lighting Service) incandescent lamp. This is extremely misleading. The only 'equivalence' is that both are designed to produce light, but the technology involved in CFLs makes them an altogether new product. As a new product they should be subjected to new tests, based not only on their ability to produce light, but also on the impact of the new technology on safety - electrical and environmental. This has not been recognised by politicians, and appears to have also been missed by the regulators - whether intentionally or otherwise is unknown.

As one unfortunate homeowner (see Fire Risk below) pointed out to the press ... "I don't read light bulbs, I wouldn't think I'd ever have to.". This is in large part because no-one has ever had to do so before, and since the CFL is marketed (and promoted) as simply a more efficient light bulb, it is assumed to be equivalent in all significant respects. The marketing has concentrated almost exclusively on the advantages of power savings and less heat, but has never explained that this is new technology (from the consumer's perspective), and that there are major differences that must be considered. A CFL is not simply a different type of lamp - given the amount of technology embedded in the small housing, it's an appliance in its own right.

Because this isn't explained, people are expected to read the packaging (which no-one ever did before), and decipher often cryptic symbols that indicate certain criteria that determine the life and possible safety of the product. People don't. They are sold an 'equivalent' product that they are told will save them money, and lacking any detailed knowledge of what is involved in the replacement will commonly assume that this 'new' lamp can be used in the same way as the old.

Because CFLs run at much lower temperatures, possible risks are no longer obvious. A CFL (even connected to a dimmer) may operate apparently normally for weeks or months before it fails, and it's impossible to predict exactly how it will fail. The ultra-cheap electronic ballast is a new development, and is something that 99% of the populace is unaware even exists. Lamps are such commonplace commodities that the average consumer will simply assume that they are all equivalent products - indeed, the lighting industry and government bodies alike insist that the CFL is an equivalent to a normal GLS light bulb.

If there was ever any doubt, this article should disabuse you of that notion pretty quickly. That CFLs have their place is obvious - everyone likes to save money and help the environment if they can do so with little or no sacrifice, and there are many applications where CFLs are perfect replacements for GLS lamps. There are also many situations where CFLs are absolutely not appropriate, but this is rarely stated other than occasionally in fine print on the packaging (that almost no-one reads anyway). Even though this article has been on-line since 2007, it's hardly mainstream.

About 2 months before these latest amendments were written, a local TV station raised a fuss about CFLs. They had only just 'discovered' that CFLs contain mercury. This is information that is readily available, but you'd need to know what to look for in order to find it. Put another way, if you already knew that CFLs contain mercury you'd have no difficulty finding out that they do, but, if you didn't know, the information hardly leaps out at you. Even if you are the type to read the packaging, in many cases there is little mention of mercury, although it seems that new regulations insist that it be stated.

Overall, the CFL is not simply a different type of light bulb - it's an entirely new product, with an entirely new set of rules for safe operation. This has not changed at all since this article was first published in 2007.

Although it appears simple, the modern incandescent lamp is the result of many years of research. Small but important improvements have been made over the years, and considering the minimal cost of a typical 75W lamp, they are quite remarkable value for money. There is a veritable feast of available information on the development of the incandescent lamp, and it would be foolish of me to even attempt to cover the topic. A web search is recommended for those who want to know more. I only intend to cover the topics that I feel are important to the discussion at hand ... should they be banned?

The light source is simply a filament - a coil (or a coiled coil) of thin tungsten wire. This is supported on a pair of wires, and the whole is enclosed in a glass bulb. When an electric current passes through the filament it gets hot, in fact it gets to such a high temperature that it glows white - the operating temperature (closely related to colour temperature) is typically around 2,400 - 3,100 K (about 2,130 - 2,830°C). It is standard practice to rate colour temperature in Kelvin (the term 'degree' is not used). Zero Kelvin is about -273°C, and represents the complete absence of heat (absolute zero).

In the early days, the bulb was evacuated (a vacuum), but this leads to the tungsten 'boiling off' and being deposited on the glass. Because of the loss of metal, these early lamps had a short service life, and most standard lamps are now filled with a low pressure inert gas (argon, nitrogen, etc.). The use of an inert gas does not prevent the liberation of molecules of tungsten, but it does slow the process significantly.

Because of the presence of the gas, modern lamps usually have a section of the support deliberately thinned to act as a fuse. When the filament breaks, it can cause an arc or fall across the support wires, and the fuse prevents excessive current flow.

By using a halogen (typically either iodine or bromine gas), an interesting phenomenon occurs - the halogen causes vaporised tungsten to be re-deposited on the filament. This is one of the main reasons that quartz-halogen lamps last so long (as well as usually having much thicker filaments than conventional high voltage lamps). As a side issue, quartz is used because ordinary glass would soften or melt at the typical operating temperature of a quartz-halogen lamp. Halogen lamps are usually far more efficient than traditional incandescent lamps, and may reach 9-10% efficiency. Not wonderful, but better [1].

Because incandescent lamps are pure resistance, they have unity power factor. This means that the electricity meter registers exactly the power drawn by the lamp. A 75W incandescent lamp (traditional or halogen) draws 75W from the mains (326mA at 230V). Where any electrical device has reactance, the power factor will be less than unity. This means that it may draw 75W (and that's what you will be charged for), but might draw a current of 652mA (again at 230V). This is 150VA, and although you don't pay for the extra current, the supply utility still has to generate and supply that current through the entire grid. This 2:1 ratio of VA to Watts represents a power factor (PF) of 0.5 - generally considered to be the lowest acceptable PF for normal usage.

The constituent materials in a standard incandescent lamp are all used in small quantities, and nothing is toxic by normal definitions. The basic ingredients are ...

Although it is possible to recycle incandescent lamps, the small amount of all material and lack of anything even remotely toxic probably makes the process uneconomical. IMO this is a pity, because I prefer to recycle everything I can, but economics must intrude somewhere I suppose  .

.

Incandescent Lamp Characteristics

Benefits ...

Deficiencies ...

In may be premature to write off the poor old incandescent lamp anyway. General Electric (GE) is apparently developing an incandescent lamp that matches the efficiency of typical CFLs [4], and no doubt others will follow before too much longer.

One site I looked at claimed that it takes about 1kWh to manufacture an incandescent lamp. No further details were given.

The Compact Fluorescent Lamp (CFL) also seems simple from the outside - you can't see what's inside, but there is quite a bit of technology involved (see below).

The tube itself contains around 5mg of mercury, mercury vapour (mercury is an extremely potent neurotoxin ), and various phosphors that emit visible light when stimulated by the intense ultraviolet radiation emitted by a mercury arc discharge. There is still some conjecture regarding the toxicity of the phosphors, with various claims and counter-claims. It is generally better to err on the side of caution with any chemical compound, so a designated recycling program is essential before the mandatory use of CFLs becomes a reality. Such a program should be in place now to deal with standard fluorescent lamps, as these also contain the phosphors and the mercury. In Europe, the WEEE Directive (Waste Electrical and Electronic Equipment) has already addressed the issue of recycling, but it has not been mentioned so far for Australia. Interestingly, some CFL manufacturers have even stated that the expected boom in CFL sales will create problems with the mercury (it's true - look it up).

Proponents of the anti-incandescent lamp stance will point out that the reduction in energy usage by using CFLs will prevent far more mercury entering the atmosphere than will be liberated by the (inappropriate) disposal of defunct CFLs. While this may be true at present, there are serious moves afoot to reduce mercury emissions from coal-fired power stations [2], so the point may be lost to scientific advances before too long. Consider too that mercury from power stations is distributed, not concentrated in landfill.

The CFL is not as efficient as a standard full-size fluorescent lamp, but still manages to achieve quite respectable performance. An efficiency of around 6-10% seems to be indicated, but there are so many factors that influence the apparent efficiency that direct comparisons are difficult.

The technology used in modern CFLs is quite astonishing for a throw-away product. The incoming mains is rectified to obtain DC, and there is some degree of ripple reduction by a filter capacitor. A switchmode inverter is then used to obtain the necessary voltage to strike the arc within the tube, and additional circuitry is included to limit the current to the nominal value needed to produce the required power. All of this must fit into the base of the lamp itself. Dedicated lamp housings are becoming available so that only the tube itself needs to be replaced (at present they seem aimed primarily at commercial applications).

The disadvantage of all this is that the power factor is far worse than an incandescent lamp. You don't pay for the extra current drawn, but the power utility must still provide cabling, transformers and generating plants that can handle the total load current, regardless of the power factor. There is still a significant saving, but this could easily be eroded because of two significant failings of CFL technology as it exists at present.

Readily available CFLs cannot be dimmed effectively with a normal wall-plate dimmer, so must run at full power at all times (some provide a low power setting by switching off and back on quickly). Incandescent lamps are often dimmed to very low power levels for extended periods (while watching TV for example), so their power usage will be perhaps 20% of the rated power, in some cases even less.

CFLs will fail prematurely if switched on and off many times a day. Many people already know this, so may be tempted to leave lights on that would otherwise be switched off, so a household might have 4 or 5 CFLs running for hours at a time, where they may have had only 1 or 2 incandescent lamps switched on (and possibly on dimmers, thus reducing power significantly).

Another area where CFLs cannot be used is at very low or very high temperatures. Most will not start at all at temperatures below -20°C, and a lot will refuse to start (or will have very low light output) at even higher temperatures. Because of the electronics in the base of the lamp, temperatures above around 50°C will shorten their working life considerably. Electronics components have highly accelerated failure rates as temperature goes up from the standard 25°C 'reference' ambient.

The constituent materials in a typical CFL vary widely, because there are many technologies that can achieve the same (or at least similar) results. In general though, the basic ingredients are ...

Items marked with * are in addition to the basic ingredients for an incandescent lamp. Although it is possible to recycle CFLs, there is little or nothing in Australia geared towards any form of recycling of these (or any other) fluorescent lamps. This must be addressed and fully functional before any ban on incandescent lamps can be implemented.

Items marked ** are in addition to materials used in conventional lamps, but are either toxic, or may be toxic when mixed with other chemicals in landfill and/or when heated to high temperatures.

Compact Fluorescent Lamp Characteristics

Benefits ...

Deficiencies ...

Note that premature failure (* above) is very difficult to judge unless the switching is logged. Some makers quote switching cycle data, most don't. Some newer models of CFL use active inrush current limiting, so will not stress switching systems when CFLs are used in large numbers (from the same switch). A standard CFL has the potential for an inrush current of up to around 4 to 5A, since it is limited only by the equivalent series resistance (and to a lesser extent the capacitance) of the filter capacitor, along with any series resistance. Series resistance will usually be kept to a minimum, as it contributes nothing more than heat (and reduces overall efficiency).

From much of the above, the reader could be excused for thinking that I dislike CFLs - I don't! I use them wherever possible (or practical), and for the most part I will never change back to incandescent lamps in the places where CFLs (or LEDs) are ideally suited. At the same time, I will not change to CFLs where it is obvious that traditional lamps are more practical (such as the lights in my house that have dimmer controls). My workshop is almost exclusively LED tubes now, but with CFLs used in most of the desk lamps I use for drill presses, lathe, milling machine, etc. Many other light fittings in my home are also fluorescent - there are actually only a few incandescent lamps used (down to about 2 as of early 2013  ). I strongly recommend that others use fluorescent, CF or LED lamps wherever possible - the modern CFLs are considerably better than the originals that people may have tried, and they should be used wherever it is sensible to do so. LED technology is advancing in leaps and bounds, prices are falling and quality improving - this has to be a good thing.

). I strongly recommend that others use fluorescent, CF or LED lamps wherever possible - the modern CFLs are considerably better than the originals that people may have tried, and they should be used wherever it is sensible to do so. LED technology is advancing in leaps and bounds, prices are falling and quality improving - this has to be a good thing.

However, an outright ban on incandescent lamps is simply foolish - as has been demonstrated in the UK and California, where calls for a ban have been largely met with the contempt they deserve. However the moronic government in Australia has simply trampled on our rights to choose without even asking us.

The site I mentioned above that claimed 1kWh to manufacture an incandescent lamp also claimed 4kWh for a CFL. I would expect this figure to be less than half the real (total) energy usage. The ceramics and semiconductors alone would easily account for that figure. My guess (and that's all it is) is that somewhere between 10 to 20kWh would be needed to produce all the materials used and make the lamp. Distribution cost is higher because the CFL weighs a lot more.

A very common question in forum sites is along the lines of "My light fitting says that the maximum lamp power is 60W. Can I use a 20W CFL that has the same light output as a 100W lamp?"

The standard answer given in Q&A sites is an unqualified "yes", however there is one major factor that must be considered but rarely gets a mention. Some CFL packaging states that the lamps must not be used in fully enclosed light fittings, but in reality, no CFL is suitable. The reason is temperature. Because of the electronic circuitry, all CFLs can only be used where they have reasonable ventilation to prevent overheating. Excess heat doesn't bother an incandescent lamp, and temperatures well in excess of 100°C won't cause them any problems at all. Remember that the filament is already operating at around over 2,000°C, so a bit more won't hurt (although wiring insulation and even the lamp socket itself will be damaged eventually). Some sealed light fittings use high temperature wire internally, because they get too hot inside for ordinary PVC insulation - which will fail quite quickly at elevated temperatures.

Because of the electronic circuitry, the maximum ambient temperature for a CFL should remain as low as practicable, with most manufacturers warranting their products to a maximum of 50°C. This has forced a complete re-design for recessed downlights [7], and many other light fittings are completely unsuitable. If the heat from the tube and the electronics cannot escape, the temperature will potentially rise to well over 50°C, and the lamp's life and light output will be badly affected.

There are far too many factors that need to be considered to even try to answer the question here, but as a guide, if the light fitting is completely sealed (or recessed into the ceiling with no way for hot air to escape) then the answer is no. Not simply "no" to the question, but no to the use of any CFL in a completely sealed (or even just poorly ventilated) light fitting.

Many of the sites that offer advice have zero technical expertise, and a lot seem to assume that CFLs emit almost no heat at all. Anyone who has used one knows that this most certainly is not the case. This is shown very clearly below ...

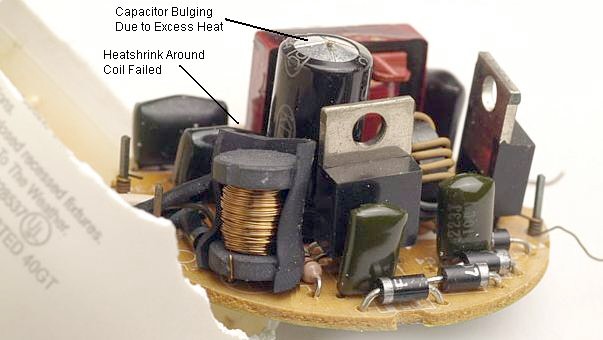

Figure 2 - CFL Killed by Overheating [A]

This is a perfect example of what happens. The photo was sent to me from the US, and the lamp failed after about 200 hours - somewhat shy of the typical claimed life (to put it mildly). You can see that the electrolytic capacitor is bulging at the end, and it had ruptured its safety seal and leaked electrolyte. The heatshrink tubing around the inductor got so hot that it split, and the 'Greencap' capacitors are all seriously discoloured.

So, what would cause this? Simple. Most existing home light fittings are designed for conventional incandescent lamps, and have little or no ventilation. Many of the popular fittings typically have no ventilation at all - especially the 'oyster' style, which has a glass dome clipped over a metal ceiling mount unit. There are many other styles of light fittings (luminaires) that are either fully enclosed, or are open only at the bottom.

The heat will build up quite quickly, and because it has nowhere to go, will remain in the fitting. Since the maximum ambient temperature for an operating CFL is 50°C, it will only take a few minutes to reach this temperature. Test results for this are shown below. The result is quite clear, although (for whatever reason) some CFLs will manage to survive in some enclosed fittings. Unfortunately, quite a few people who have commented on this particular topic seem to think that because they have not had a failure, that this somehow implies that no-one else will either. One word sums up my response to these claims ... bollocks!

Do not use CFLs in fully enclosed light fittings !

As an example of the ratings of one of the key components in any CFL electronic ballast, we can examine the typical specifications for aluminium electrolytic capacitors. These are supplied in either 85°C or 105°C temperature grades, and the manufacturers usually claim a 'typical' life of 1,000 - 2,000 hours when operated at the maximum temperature. This is obviously far shorter than the 'typical' life of most CFLs, and the only way the capacitors can be made to last longer is to operate them at a lower temperature. Should the temperature exceed the maximum rated, then the life of the capacitor will be reduced dramatically. The same principle applies to most of the other components used too.

Semiconductors (transistors or MOSFETs) will run fairly hot in most CFL circuits - in fact they are responsible for a fair proportion of the total losses within the system as a whole. These components must never be allowed to exceed a junction temperature of (usually) 150°C - and this means that the case temperature must be somewhat lower than the maximum permissible. The only way to get the maximum life from any CFL is to keep the electronics as cool as possible - preferably well under the manufacturers' recommendation of 50°C.

Ultimately, this is the biggest downfall of the technology, and means that if incandescent lamps are banned, there will be an enormous consumer backlash when long-life lamps fail well before their supposedly short lived incandescent predecessors ever would. The environmental impact of thousands of prematurely failed compact fluorescent lamps is also a disaster - especially when you consider the energy that went into making them. This will (not might) result in exactly the reverse of what governments are 'planning' - with a net energy loss and a huge consumer outcry.

Figure 3 - Light Fitting Suitability

The above is a small example of fittings that are (or may be) suitable, and some of those that are not. Needless to say, there are hundreds of different styles, and only a full inspection (and perhaps a controlled test) will reveal if the fitting is or is not capable of being used with a CFL. The key factor is ventilation. Any fully sealed fitting is almost certainly unsuitable, because there can be no air circulation, and the temperature will rise sufficiently to cause premature failure. Elevated temperature also reduces the light output, so you will not be able to get as much light as you hoped for, as well as shortening the life of the electronic circuitry (probably drastically).

There isn't a technological breakthrough around the corner that will fix this - electronic equipment cannot be made to function properly and reliably at severely elevated temperatures. Householders will be faced with the rather daunting (and very expensive) requirement to replace all non-ventilated light fittings with new ones that have sufficient airflow to maintain a safe temperature. Because the fittings must be installed by a licensed electrician in most countries, this is yet another expense.

Any potential saving in energy bills is gone ... for quite a few years, until the cost of the fittings and their installation is amortised. There is also the enormous waste of replacing perfectly good light fittings with new ones, so the environmental impact is also negative - probably by a large margin. It will take many, many years before the household or the environment start to get any real benefit, because of the vast waste that was created to impose an 'environmentally friendly solution'.

In the UK, the Market Transformation Programme stated that ...

The availability and the current stock of light fittings heavily influence what types of lamp are being used in the domestic sector. Research showed that less than 50% of the existing light fittings are suitable to fit a compact fluorescent lamp.

This means that, on average, householders will have to replace more than half of all their light fittings to accommodate CFLs. I doubt they will be pleased if this is forced upon them, either in the UK, Australia, Europe, or anywhere else! It is also likely that lighting retailers will be rather annoyed, since a great deal of their existing stock will have to be scrapped. Doesn't sound quite so environmentally friendly now, does it?

One other area has been pointed out as well - spot lamps. While these are primarily decorative and it can be argued that they are not essential, the fact remains that people use them, and will want to continue doing so. Because of the large radiating surface of a CFL, it is not possible to focus them to anything like the same degree as a bi-pin quartz halogen lamp. These are almost a point source, and are easily focused to a very narrow beam. Even a conventional incandescent lamp can be focused fairly well - far better than any CFL.

For displays and in some home decorating schemes, designers use the 'sparkle' effect that one can get with point source lighting. This simply cannot be achieved with CFLs because of their large area. While LED lamps can achieve point source sparkle effects, they are not seen as a mature technology yet, and luminous efficacy is only marginally better than incandescent lamps for the majority. Colour temperature and colour rendering index of LEDs are currently not well controlled, and in general are far worse than CFLs. While one can argue that none of these special effects are needed to sustain life as we know it, people have expectations. They get very annoyed if they can no longer do what they want - or used to be able to do. Whether this is important or not depends entirely on your job or personal tastes.

This is an important area, and tests were conducted to find out just how hot a CFL would get in a sealed enclosure. I fabricated a test jig that would show the effects and ran two versions of the test simultaneously, using two temperature sensors. The temperature was measured at 10 minute intervals. The main test had the CFL set up as shown in the sub-page, with a bead thermocouple taped to the lamp socket. This was installed in a housing. The second set of test results were obtained with a probe thermocouple that was used to measure the air temperature inside the test fitting, with the very tip of the probe just touching the metal top cover. The probe was inserted into the hole where the bead thermocouple lead exits the housing. Measured temperatures were ...

| Time | Temperature (°C) | |

| (minutes) | Bead | Probe |

| 0 | 23 | 23 |

| 10 | 48 | 34 |

| 20 | 55 | 39 |

| 30 | 58 | 40 |

| 40 | 58 | 42 |

This is not a good result. A 10W CFL in a 3 litre enclosure is over temperature in just over 10 minutes. The full test details and a photo of the test jig used have been moved to a sub-page ... Click Here to View.

The temperature inside the plastic housing of the CFL's electronics will be 20-25°C higher than measured by either probe or bead thermocouple. A higher power CFL in a smaller (or even the same size) housing that is completely airtight (as required for outdoor use) will get far hotter (and faster) than shown in the table. Any claims that more than 50% of existing light fittings are unsuitable for use with CFLs is completely justified on the basis of this test.

There have been a few reports of CFLs literally exploding when switched on. While it isn't really possible to give a detailed analysis without having such a unit in my possession, there are a few reasonable explanations that may cover the issues.

Moisture: If a CFL is operated where it is exposed to outside air and/or moisture, there is a chance that condensation may collect on the PCB. Because of the high operating voltages (325V DC for 230V mains), even a small amount of moisture may be enough to cause significant current between PCB tracks. This is commonly called 'tracking' and the initial discharge carbonises parts of the printed circuit board substrate - commonly a paper-epoxy or paper-phenolic material.

Once an arc is started, it will continue until enough material has been burnt away that there is no longer a conductive path - this means that PCB tracks, components, or anything else in the circuit can be blown apart - often quite violently and usually with lots of black soot and at least some smoke.

Insects, Dust, Etc.: Small insects can get into most CFL housings easily enough, and are more than capable of starting an arc. This will have the same results as moisture, with a violent cascade of failures within a few milliseconds.

Component Failure: Because the CFL is a throwaway product, the cheapest components that will work with the voltages involved are used. For example, the CFL intestines shown in Figure 3 (below) includes a 150nF, 400V DC capacitor directly across the mains. This device is absolutely not designed for direct connection across 230V AC, and it will fail. Usually, specifically designed mains film capacitors die quietly, simply losing capacitance as more and more of the metallised layer is damaged. Most CFLs use non-mains rated capacitors, and these commonly fail with acrid smoke and pyrotechnics - especially since they are often used well above their safe current ratings.

Inrush Current: As noted above (and below), most CFL electronic ballasts have a rather high initial inrush current, which can easily exceed 5A and often a lot more. This current is limited in some electronics by one component - the main filter capacitor. If it has a relatively high ESR (equivalent series resistance), this will hopefully be enough to limit the current to a safe value. The problem is that as an electrolytic capacitor gets hot, the ESR falls. When the lamp is cool, the ESR should be high enough to prevent problems, but if the lamp is switched on while still hot, the ESR will be very much lower - as little as one tenth of its original value. A much higher initial current flows (it could easily reach 20A or more), and may cause a diode to fail, for example. One diode failure in a bridge rectifier circuit will always be followed by another, and within milliseconds, the filter capacitor may be connected directly across the mains. Spectacular failure is guaranteed within well under 100ms (one tenth of a second).

The failure modes described above are educated guesses, but the lamp failures are not. The possible causes listed are all quite plausible, and all can be demonstrated. Which is the most likely or most common is unknown at this stage, and will remain so until one of mine fails so it can be analysed, or I find some additional information ... either by more searching on the Net, or if some kind reader lets me know what was found in a few failed CFLs.

On this basis, use of CFLs in bathrooms is obviously not a good idea - some manufacturers warn against using CFLs in bathrooms, most don't. Lots of water vapour from hot showers is likely to cause condensation that could cause spontaneous failure. Likewise (well apart from the known problems of CFLs not even starting if it is cold enough), outdoor use means that water may enter the lamp itself, or insects, small spiders and other matter may also get inside. As detailed above, using a fully sealed housing will shorten the life of the lamp dramatically , so our options are very limited.

It seems that as far as many manufacturers are concerned, melted plastic, evil-smelling smoke and other similar issues are considered normal modes of failure at the end-of-life of a CFL. According to EnergyIdeas, one manufacturer stated that "some overheating after a lamp fails and the ballast remains energised may cause minor melting of plastic and leakage of non-toxic glue." He indicated that there is a fuse that will blow before fire danger develops. The implication is that this kind of failure is within normal expectations.

It seems that as far as many manufacturers are concerned, melted plastic, evil-smelling smoke and other similar issues are considered normal modes of failure at the end-of-life of a CFL. According to EnergyIdeas, one manufacturer stated that "some overheating after a lamp fails and the ballast remains energised may cause minor melting of plastic and leakage of non-toxic glue." He indicated that there is a fuse that will blow before fire danger develops. The implication is that this kind of failure is within normal expectations.

A so-called 'normal' failure is shown in the image - I must say that I do not consider such damage to be normal by any definition of the word. More information may be seen here. There are a couple of photos of failed CFLs, some additional information, and technical data that was moved from this page.

These claims make the CFL the only consumer product ever made that is expected to fail in a comparatively spectacular manner. When any other product fails, smoke, melted plastic and/or small fires (whether seen or not) are considered abnormal - protection devices are fitted to ensure that any normal failure is 'silent' - the device simply stops working, and you don't need to ventilate your house afterwards. There will be exceptions, but these should be rare, and triggered by an abnormal failure - not by a reasonable percentage of units that have simply reached their end-of-life.

Various bodies have reported consumer concerns about CFL failures, and we know for a fact that a significant number of these lamps have not failed silently, but have advertised their demise by making noises, emitting smoke, or other behaviour that is simply not expected of any normal consumer product. None of this is helped by the fact that most packaging fails to make it absolutely clear whether the lamp is suitable for various light fittings (luminaires), if it can be used outdoors, or even state that the lamp must not be used with a dimmer ... even if set to maximum.

There are countless examples of failed CFLs at Doug Hembruff's site, and some of the photos and descriptions are sufficient to make one think that perhaps it is the CFL that should be banned. Because of misleading advertising and packaging, and a number of zealots insisting that CFLs can (or must!) be used anywhere at all (but never citing any proof or documentary evidence), users often have unrealistic expectations. No-one expects the lamp to fail and burn - this is simply not anticipated with any consumer product, and nor should it be.

Above, it was indicated that CFLs are fitted with a fuse. Unfortunately, the most commonly used 'fuse' is a fusible resistor, and these are simply not suited at all when in close proximity to a thermoplastic enclosure. The photo on the right is a 10 ohm 1W fusible resistor, subjected to 8W. That this is more than capable of melting and charring plastic is pretty obvious - the temperature is roughly the same as a car cigarette lighter, and will easily set fire to any flammable material that comes in contact with the resistor body. (Please note that the resistor is not quite as hot as it looks in the photo. It was enhanced a little so everything was more visible, and that makes it look hotter.)

Above, it was indicated that CFLs are fitted with a fuse. Unfortunately, the most commonly used 'fuse' is a fusible resistor, and these are simply not suited at all when in close proximity to a thermoplastic enclosure. The photo on the right is a 10 ohm 1W fusible resistor, subjected to 8W. That this is more than capable of melting and charring plastic is pretty obvious - the temperature is roughly the same as a car cigarette lighter, and will easily set fire to any flammable material that comes in contact with the resistor body. (Please note that the resistor is not quite as hot as it looks in the photo. It was enhanced a little so everything was more visible, and that makes it look hotter.)

The ESA (Electrical Safety Authority, Canada) is concerned that it can be difficult for consumers to distinguish between what is normal and what may be a precursor to fire or some other hazardous condition. As a safety precaution, they encourage consumers to replace CFLs at the first sign of failure or aging - not always easy with a lamp in a light fitting on the ceiling! The early warning signs to look for include flickering, a bright orange or red glow, popping sounds, an odour (typically a burning smell), or browning of the ballast enclosure (base). The ESA has pointed out that CFLs should not be used in exactly the same places as indicated elsewhere in this article, and I suggest you read their information on the topic.

The ESA is well ahead of Australia (as well as many other countries), and there's not even talk of an incandescent ban in Canada. They are encouraging product manufacturers to review packaging information to support consumers in making safe product decisions. The ESA also has plans underway to update the existing Canadian safety standard for CFLs to address consumers' end-of-life product issues.

Many of the parts used in CFLs are simply not suited to the purpose. There is more technical detail in the Exploding CFLs and Other Failures sub-page, along with the failed CFL photos (Updated 17 Dec 2012).

It has to be said that the current situation is not merely intolerable, it is a disaster waiting to happen. Many people use lights (often on timers) when they are away, so that it looks like there's activity in the home. I wouldn't use any CFL as supplied for unattended use, because there is no way to know when (or how) it will fail, or what exactly will happen when it does fail. I'd be perfectly happy to use a conventional fluorescent lamp in this role, as I have never seen one 'crash and burn' when it fails. Likewise, an incandescent lamp will fail silently - no smoke, fire or brimstone - they just stop working. Unattended operation may not pose a big risk, but it's something we never had to worry about before.

There's a surprising amount of information that needs to be understood to realise the full implications of a complete ban of incandescent lamps, and more information will be supplied as it comes to hand. In the meantime, as I continue research, I hope that the amount I have been able to supply so far helps you to understand some of the potential problems.

It's interesting to see how much electronics has been packed into such a tiny space. It is also worthwhile to perform some measurements. I also recommend a web search - there is much to learn and a vast amount of information is available.

It is worthwhile to look at the circuit (or equivalent circuit) of a CFL and an incandescent lamp ...

Figure 6 - CFL Simplified Circuit [3] |

Figure 7 - Incandescent Equivalent Circuit |

The level of technology for the CFL (even simplified) is quite clearly vastly greater than for a conventional lamp. Likewise, the potential waste material at the end of its life means that recycling is not optional for CFLs. Suitable initiatives should be put into place immediately, if not sooner, and should be mandatory for all forms of fluorescent lamp.

It is interesting to look at the guts of a typical CFL. The photo in Figure 8 was sent to me, Figure 9 is a standard incandescent lamp.

Figure 8 - Inside a modern CFL |

Figure 9 - Typical Incandescent Lamp |

There is some additional info and another photo in a new sub-page ... Click to View. The newer CFL featured has some measure of power factor correction - not perfect, but a lot better than most. The old one shown (formerly Figure 10) is purely for interest's sake.

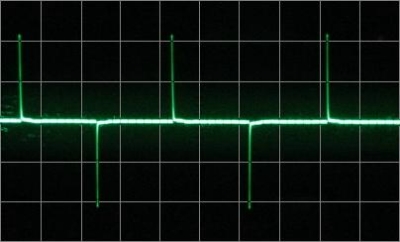

As you can see, there's no contest as to which takes more energy to produce, and look at all the parts that will be discarded when a CFL fails. The incandescent lamp uses so few materials (and so little of them) that it weighs only 31 grams, vs. 98 grams for a 15W CFL. The incandescent lamp shown is 100W, so is a little heavier than a lamp with claimed equal light output to that of a 15W CFL.