|

| Elliott Sound Products | Hybrid Relays using MOSFETs, TRIACs and SCRs |

Main Index

Main Index Articles Index

Articles Index Electromagnetic relays (EMRs) remain one of the most popular switching devices ever created. They have low losses, and are used in countless applications for consumer, automotive and industrial systems. When used within ratings, relays have a very long life (typically up to a million operations), and are very reliable. However, they are supplanted in many systems by SSRs (solid-state relays) using TRIACs or back-to-back SCRs. Being 'solid-state' devices, they have an almost infinite life, provided they are kept well within ratings at all times.

However, SSRs are not without their problems, one of which is power dissipation. Typically a TRIAC or SCR has a constant voltage drop when conducting, and it's such that these devices dissipate around 1W for each amp of current. For a load that draws one or two amps, this is of little concern, as 1-2W is easy enough to dissipate. The situation changes rapidly if the current is 10A or more, and a heatsink becomes essential. Indeed, this is still the case for lower current, or the device(s) may otherwise exceed their maximum rated operating temperature (typically a junction temperature of 125°C).

Power dissipation becomes a limiting factor for currents of 20A or more, and most high-current SSRs end up in fairly bulky packages that need even bulkier (and expensive) heatsinks. This is not desirable for a variety of reasons, and particularly because consumers and systems engineers are nearly always looking at ways to minimise wasted power. This has become more critical as there are frequently (IMO often unrealistic) requirements to fit the highest possible power into the smallest space.

Switching DC proves particularly difficult with high voltages and/ or high current. Predictably, the combination of both creates some significant problems. In terms of DC, anything over 30V is a problem, and with even relatively low currents (e.g. 5A or so), there will be a significant arc as the contacts open, breaking the circuit. However, the traditional electromechanical relay has very low losses when the contacts are closed. Contact resistance will generally be only a few milliohms, so power dissipation is negligible. For example, 30A contacts with 3mΩ contact resistance will dissipate only 2.7W, where a TRIAC would be dissipating 30W at the same current. An electromechanical relay also has an actuating coil, but these normally dissipate somewhere between 500mW and 1W for most standard types. I've tested a 10A relay at 10A and obtained a contact resistance of 6mΩ (increasing to 6.6mΩ at 20A). At rated current, that's a dissipation of only 600mW.

While it's easy to design a hybrid system when the DC shares a common ground (or other rail that's common both to the relay and the electronics), greater difficulties are assured when complete isolation is required (such as switching mains voltage). Nothing is insurmountable of course, and I commend the reader to look at the article MOSFET Relays to see some examples. As described, MOSFETs are good contenders for low-loss switching of AC or DC, but they still have internal resistance (few are less than 20mΩ) so will dissipate power. Assuming 20mΩ and two MOSFETs (a total of 40mΩ), dissipation is 30W with the same current as before (30A, AC or DC). EMRs will usually have less than 6mΩ contact resistance (5.4W contact dissipation for the same current).

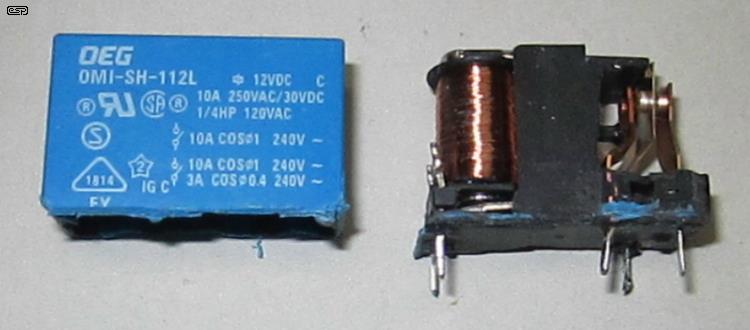

Photo Of Dismantled Sample Relay

The relay style used for the examples presented is shown above. This is a very common relay, and it's the same one recommended for Project 39 (mains soft-start circuit). The essential ratings are shown on the cover, namely 10A at 30V DC, 10A at up to 250V AC (resistive, cosΦ = 1), or 3A at 240V with a power factor of 0.4 (cosΦ of 0.4 - inductive or capacitive). Although it's hard to see, the contact clearance is about 0.4mm. Based on the 'quick and dirty' estimate of 3kV/ mm, the contacts can withstand at least 1,200V without 'flash-over' (breakdown of the air). However, it would be a very foolhardy design if it were stressed to that voltage. The safe limit is as marked on the relay - 250V AC (353V peak). The relay shown is a '1 Form C', meaning a single contact set with changeover contacts. This is the same relay that measured 6mΩ contact resistance. Higher current relays can usually be expected to have less. We only use the normally open contacts in the designs shown, so a '1 Form A' relay can be used.

Photo Of Relay Destroyed By Arcing

The photo above was submitted by a reader, and shows what happens when a small relay is expected to break a high-current arc. The contacts and their supports are totally destroyed, with only the 'stumps' of the contact arms remaining. A similar photo of an industrial (much more rugged) relay is shown in the Relays - Part 2 article. Once an arc is maintained by the applied voltage and current, there is almost nothing you can do to prevent subsequent failure. The only option is to prevent the arc from forming in the first place.

For hybrid relays, any semiconductor switch can be used to bypass the EMR (electromechanical relay), including BJTs (bipolar junction transistors), MOSFETs, IGBTs (insulated gate bipolar transistors), SCRs (silicon controlled rectifiers, aka thyristors) or TRIACs (bidirectional AC switch, originally a trade mark, but now generic). Each has advantages and disadvantages, but the only solution for switching audio is to use MOSFETs, as all other devices introduce gross distortion. For most power control systems this is irrelevant, and there are only a few places where high-current audio requires switching (DC protection circuits don't need to be linear, as they only operate under fault conditions).

Most commercially available hybrid relays use TRIAC or SCR 'solid state' switching in tandem with the EMR. This is fine for switching mains or other mains frequency voltage to a load, and they are a reliable and mature technology. However, if you need to switch high-current audio signals, they are of no use. In addition, they cannot be used with DC, nor if there is a DC component in the switched supply voltage. For the things that most audio people will want, the only method that will work is to use MOSFETs.

No BJT switching circuits are shown here, as they are uncommon in hybrid relays. Unlike MOSFETs or any of the other switching systems, a BJT requires considerable base current to turn on fully, and this is difficult to provide with any common optoisolator. It can be done of course, but I don't know of any commercial circuit that uses them.

Note that while some commercial hybrid relays may turn off the 'solid-state' part of the circuit when the relay contacts are closed, there is no requirement to do so. The circuitry becomes far more complex, and while it does save a small amount of power (around 10mA or so) this is not worth the added complexity. The circuits shown here keep the MOSFET, TRIAC or SCR turned on for the duration of the switch-on cycle, and only the MOSFET will dissipate any power at all (about 10mW, assuming a contact resistance of 6mΩ). It's fair to say that this is negligible.

In the circuits shown, there is no attempt to reduce the EMR's drop-out time using zener diodes or other techniques. All circuits shown use a diode for back-EMF suppression, and while this causes the contacts to remain closed for longer after de-activation, the solid state switching circuit is delayed for long enough to ensure this isn't a problem. Relay drop-out can be made faster as described in Relays - Part 1, but this may require additional circuitry to handle the higher back-EMF without compromising the electronic switching or delay circuits.

While the circuits below show a comparator as the timer, this does make the circuit more complex. I showed comparators because their operation is easy to understand (the output takes the polarity of the most positive input), and they are common in precision time-delay circuits. However, the time delay can be implemented with alternatives, as shown in Section 6. Feel free to use any timer with any switching circuit, as they are comparable in all respects. The time delay for all circuits is about 40ms (after the relay supply is removed).

One thing that you'll see over and over again elsewhere is hybrid relays using zero-crossing (aka zero-voltage) detection. The loads that can be switched this way are very limited, being incandescent lamps (now becoming extinct) and switchmode power supplies. The latter includes the SMPS used in most LED lamps, but as most are relatively low power, zero-cross switching is of limited value. Many loads are inductive, including mains-frequency transformers and one of the most common of all - motors.

Although these are always referred to as being inductive, this is only true at power-on and/or with no load. When loaded (even to as little as 10%) they are only partially inductive. The critical part is at power-on, and zero-cross switching is the worst possible option, as it guarantees maximum possible inrush current. Almost without exception, 'random' switching is used with motors and transformers, often controlled by a manually operated switch or a process controller (in industrial installations). Household motors used in fridges, pool pumps and the like are switched by either a thermostat and/or a timer. These are also random - they apply power when needed, and do not consider the mains voltage phase angle.

The misguided application of zero-cross switching for everything is just that - misguided. In many cases it's assumed that zero-voltage switching must be better, because it lets people experienced with microcontrollers show off their skill, but these same people rarely have enough knowledge of purely analogue processes to understand when (and why) zero-voltage switching is or is not appropriate. I've literally lost count of the number of allegedly 'general purpose' switching systems (using SSRs or hybrid relays) that have specified zero-crossing detection for the design. It is true that there may be a small reduction of noise when switching (say) a 2kW heater at the zero-crossing, but these things are usually switched on and off over a period of several minutes (sometimes a lot longer).

A TRIAC or SCR based SSR will make electrical noise when it's conducting (see Solid State Relays, in particular section 5, where the voltage waveform of a TRIAC is shown. When used in a hybrid, this disappears except at the instant of switch on/off and it's generally unobtrusive. Making the circuit zero-voltage switching means that it's limited to a few applications, with motors and transformers excluded.

Unfortunately, once an idea (good or bad, but with a definite bias towards 'bad') gets some attention, it becomes repeated ad-nauseam until a sizeable number of people will think that it's the 'right' way to do something. Silly (or stupid) ideas are treated as gospel, and are accepted without question. This is something I've had to confront many times, and the use of zero-voltage switching is just one of many. So, unless you know absolutely that your load will benefit from zero-voltage switching, don't even attempt it.

Consider that millions of pieces of equipment are switched on and off using EMRs (which are random switching), and this isn't likely to go away any time soon (if ever - at least until AC mains distribution disappears in favour of DC). Likewise, a random switching SSR or hybrid relay is almost always the better choice except for some specific loads that require greater sophistication. For this reason, all circuits shown in this article are random switching, as are those in the SSR article.

A switching system has three major components - the power source, switching system and the load. All must be matched to the others, not just AC/DC, voltage and current, but the nature of the load. If you get your matching wrong, bad things can happen. For example, if you were to use a zero-voltage switching circuit with a 1kVA toroidal transformer, you guarantee maximum possible inrush current, every time the transformer is turned on. Everything is stressed to the maximum - the switch itself, the transformer and even the house wiring. It's quite likely that you'll trip the mains circuit breaker at regular intervals, all because you didn't realise that you used the wrong switching type. As a side issue, such a transformer doesn't need a 'special' switch, it needs an inrush current limiter. This will also reduce the load on the switch itself and ensure stress-free operation for the life of the equipment.

The following is adapted from a relay datasheet [ 1 ], and shows the derating curves for both AC and DC operation. For the relay to meet its life expectancy, the current and voltage must not exceed the limits shown by the red curve (DC) and the green curve (AC). There are two ratings, one for DC and the other for AC. Should the ratings be exceeded, the relay contacts will be subjected to arcing that will either reduce the life and/ or destroy the relay contacts. A serious overload (e.g. 14A at 56V for a power amplifier DC protection circuit) will destroy the relay - probably the first time it's used!

Figure 1 - Relay Switching Capacity

The graph shown above is quite possibly the most important graph you'll ever see when it comes to relays switching DC. The relay itself doesn't matter very much, because the only thing that normally changes is the maximum current. The data can be extrapolated for higher current relays, but unless the datasheet specifically provides a similar graph showing higher DC current switching capacities, assume that 30V DC is the maximum permitted voltage for rated current. The current derating required at higher voltages is very clear. At 40V DC, the allowable current is reduced to less than 2A, with an absolute maximum voltage of 100V DC at 500mA or less. Ignore this at your peril.

This same graph is also shown in the Relays - Part 2 article. DC loads (even within ratings) reduce the life of any relay, and high voltage and current cause arcing that reduces the life of the contacts. The idea of a hybrid relay is to offload the switching to an external device, which for most of this article will be one or more MOSFETs.

It's probable that very few readers will ever have downloaded a relay datasheet, and many suppliers don't make them available. Hobbyist suppliers usually don't, and even if you do get the datasheet, some are less informative than others. The above graph is (almost) unique, in that it's one of only two such graphs I found amongst all of the relay datasheets I have downloaded. With sixty different PDF files, the remainder failed to include anything similar. They all state that rated DC current is only permitted up to 30V, but the others did not include the detail seen above.

An electrical arc is a very potent destroyer of anything nearby, including the conductors that initiated the arc. Electrical arc welding (in all forms) is a clear demonstration of how much material can be moved from one electrode to the other, and it also demonstrates the heat produced (along with light - including short-wave ultraviolet which cause skin burns). The more current that's available, the easier it is for an arc to be self-sustaining, even at surprisingly low voltages. A 'typical' stick-welder may be supplying 50A at a voltage of only 15-20V, and melting the welding rod and work piece quite happily. The same thing happens inside a relay when the contacts open, and it's up to the circuit designer to ensure that a sustained (and therefore destructive) arc is not produced.

You might be tempted to exceed the relay's ratings once there can be no arc (thanks to the added electronics), but that would be unwise. I checked a couple of high-current relays (including a 40A automotive relay) to determine contact resistance, and it's not always as low as you may imagine. The automotive relay measured 269mV at 50A, as resistance of 5.2mΩ, and a heavy-duty octal relay measured 338mV at 50A (6.76mΩ). The power dissipated in the contacts and internal conductors can be surprisingly high - the octal relay dissipated almost 17W (although it was operated at double its rated current). The automotive relay would dissipate a bit over 8W with 40A (measured across the normally closed contacts).

One limitation that you'll come across is that many relays have a lower current rating for their NC (normally closed) contacts than for the NO (normally open) contacts. This is largely due to the fact that more contact pressure is available when NO contacts are closed by the coil. All relays use a spring to restore the armature after operation, and that spring must be weaker than the available magnetic force or the relay won't activate at all. As the armature gap closes, more electromagnetic force becomes available, allowing higher contact pressure for the NO contacts. For the applications described here, this isn't a problem. The normally open contacts are used to connect a load, assisted by whatever electronics are added.

The first option is the simplest, and will work when the relay circuit and the load supply share the same common (nominally 'ground') connection. With appropriate choice of the relay and MOSFET, you can switch almost any voltage or current you need with this arrangement. However, like anything that's been simplified to the lowest possible complexity, it's inflexible, and isn't suited for most applications because the 'ground' end of the load is floating when the relay is inactive. This is fine for motors are other simple loads, but is not acceptable where the positive supply needs to be switched, as will be the case with most electronic circuits.

Figure 2 - Simplified DC Hybrid Relay

The circuit relies on two things (both of which are normally true). Firstly, the relay is assumed to have a small delay before the contacts close, and secondly, it's assumed to have a similar delay when the voltage to the coil is interrupted. The dropout (release) time for most relays is in the order of only 5ms, but that's without the diode. Because it's nearly always included, the release time will be similar to the pull-in (operate) time, around 10-15ms. This varies from one relay to the next, but these figures are enough to work with.

While the circuit shown has limited usefulness, it is easy to analyse. When +12V is applied to the relay coil, C1 is charged virtually instantly via D2. This forces the non-inverting comparator input (U1, Pin 2) high, so the output goes high, turning on Q1 (MOSFET). This also turns on almost instantly, applying power to the load. After around 10-15ms, the relay has overcome its internal inductance and inertia and it activates, shorting the MOSFET and reducing its power dissipation to almost zero. The relay therefore carries the load current, with the very low losses we associate with relays.

When relay power is removed, C1 remains charged, and starts to discharge via R1 and the relay coil. After around 10-15ms the relay releases, but the load current is provided by Q1, so the relay only breaks a very small current at a correspondingly low voltage. There is no arc when the contacts open, regardless of supply voltage. With the values shown, the MOSFET will turn off after about 70ms, and because the relay contacts are already open there is no arc. The MOSFET is selected to suit the load's supply voltage and current, and the only limitation is the maximum DC voltage that the relay can withstand.

Average MOSFET dissipation is low (depending on the MOSFET of course), and it's only intermittent. Even if the peak dissipation is 10W or so, a heatsink isn't needed because of the low duty-cycle. If the relay is expected to operate no more than once every 5 seconds, even a fairly 'ordinary' MOSFET should keep average dissipation below 1W. Switching 50V at 12.5A or more is easy, using a 20A relay and (for example) an IRFP240 MOSFET (200V, 20A, RDS-On of 0.18Ω - pretty 'ordinary' by modern standards). While the MOSFET will dissipate a bit over 28W when the relay is opening or closing, these periods are short.

As shown, U1 is a comparator, not an opamp. While they share the same symbol, they are quite different, in that comparators operate 'open-loop' with no negative feedback. They are therefore much faster than any opamp, but almost all use an external 'pull-up' resistor at the output (R5). If you use an opamp, choose one that's fairly fast, or the MOSFET dissipation is increased.

While it may seem as if there's quite a lot involved, the whole circuit uses only a few cheap parts. The comparator needs to be fast to minimise MOSFET peak dissipation, but even a TL072 (an opamp, and much slower than a 'true' comparator) is more than fast enough for the task. If the system is controlled by a microcontroller or PIC, the comparator and associated circuitry can be omitted because the micro can control the relay and MOSFET to get the timing right. It's rather pointless showing this arrangement as it will depend on the micro being used, and everything is controlled by software.

This is the general principle behind MOSFET hybrid relays, but don't expect to be able to go out and buy one - the original idea was patented in 1997 (Patent # US5699218), but using a TRIAC instead of MOSFETs. This is a perfectly valid way to build a hybrid relay, but MOSFETs provide advantages, and are more suited for DC and linear AC applications. You can buy MOSFET relays, but most are fairly expensive and it's usually cheaper to build your own. For example, a 48V, 20A MOSFET relay may cost anywhere from AU$120 to AU$500 - each!

Most MOSFET relays you can buy are isolated, making them (more-or-less) equivalent to electromechanical relays. However, as noted above, they are expensive, and may not be ideal for use in a hybrid setup. Many have a slow turn-on time (around 1ms is typical), so dissipation can be very high for the turn-on period. With a 50V supply and a 4Ω load (the same as used in the previous example), dissipation will peak at 156W as the MOSFET turns on. While the available devices are designed for that, it limits the duty-cycle. This isn't normally a problem, because almost no-one uses relays for high repetition rate switching.

As described in the MOSFET Relays article, an IC is now available that renders all that came before essentially obsolete. The SiC8752 is a capacitively-coupled MOSFET driver that can supply far higher peak current than common photo-voltaic optocouplers (which are used in most MOSFET relays). The datasheet can be seen here, and I suggest that the SiC8752 (diode emulation) be used as it's simpler. Unfortunately, these ICs are only available in a SOIC-8 (SMD) package, and at the time of this update are hard to get (unfortunately).

The basic control circuitry is identical to that shown in Figure 2, but the MOSFET relay drive circuit uses the Si8752 to provide gate voltage to the output MOSFETs. The circuit shown below can be used with AC or DC, and for DC the two MOSFETs can be paralleled, doubling the current rating, but making the circuit polarity-sensitive (as you'd expect).

Figure 3.1 - AC/ DC Hybrid Relay Using Si8752

The control and controlled sections are isolated, limited only by the characteristics of the isolator. These are rated for 2.5kV, but I would be wary of using one to isolate mains voltages, because the minimum creepage and clearance distances are so small. With a body width of 3.8mm (typical), this may not be considered acceptable, but the IC does have approvals from all the major regulatory agencies (UL, CSA, VDE, and CQC certifications) according to the datasheet.

Operation is identical to that described for the Figure 2 circuit, with the only difference being that the diode emulator is driven with 12mA via R5. This is a compromise between MOSFET activation time and 'diode' dissipation. According to the datasheet, 'on' time for the MOSFETs is 41µs (typical) and 125µs (maximum) with 10mA, and 'off' time is typically 15µs. This may not be as fast as you'll get with direct connection of a drive circuit to the gates, but it's a great deal faster than most other isolated MOSFET drivers.

For higher speed, the value of R5 can be reduced, with a maximum permitted current of 30mA. With a 12V supply, that would mean reducing R5 to 330 ohms, but you must ensure that the comparator can sink that much current when the output is low. The LM311 comparator (for example) can sink up to 50mA, so that's unlikely to be a problem.

While there are several photovoltaic (aka PVI - photovoltaic isolator) MOSFET drive ICs available, the Si8751/2 have such a performance improvement that it's difficult to recommend any other system. ICs such as the VO1263AB and VO1263AAC (dual PVIs) or the TLP590B or APV1122 (single PVIs) certainly work, but they all suffer from having a very poor output current capability (around 15µA). This means that the MOSFET(s) turn on rather slowly, and in extreme cases may not be fast enough to start conducting before the EMR contacts close. These devices are useful, but IMO the Si8751/2 are so superior that I wouldn't use anything else.

Figure 3.2 - AC/ DC Hybrid Relay Using VOM1271

Photovoltaic optocouplers are mostly rather feeble, with a very low output current that can't charge the gate capacitance quickly. For a hybrid relay, that's not a major problem if you only need DC arc suppression. Loudspeaker protection systems are a case in point. The relay closes a few seconds after the power amp is turned on, and at that moment there's not likely to be a significant voltage present. If there's DC present, the relay doesn't close at all. A photovoltaic optocoupler will turn on the MOSFETs within perhaps 100ms or so, but the relay contacts are closed and there's little or no current through the MOSFETs. Should the relay have to open due to a DC fault, the relay contacts open while the MOSFETs are still turned on. The DC fault current is interrupted by the MOSFETs, not the contacts, so there's no arc.

The VOM1271 (Vishay) is shown in Fig. 3.2, but there are other options (e.g. TLP591B [Toshiba], APV1122 [Panasonic] or PVI1050N [Infineon]). None of these devices come close to the Si8752, but they will work well in a hybrid relay. They are not inexpensive ICs though, but compared to a commercial hybrid relay the circuit can be built for a fraction of the price. Note that only the turn-off part of the timing waveform shown below applies if you use a photovoltaic optocoupler. The relay will almost certainly close faster than the MOSFETs can turn on with a gate supply current of (typically) less than 20µA. Most of these ICs are designed to have a fast turn-off (note 'Turn Off' block inside optocoupler), so the MOSFETs are protected against excessive power dissipation. Not all photovoltaic optos use the turn-off circuit though, so choose carefully.

Note that for particularly high power applications, you may choose to use an IGBT (insulated gate bipolar transistor) instead of a MOSFET. Not all IGBTs include a reverse diode, so if your application is AC, you need to choose one that does, or add an external diode. The diode must be capable of handling the full load current. IGBT hybrid relays are not covered in any further detail here, but note that unlike the MOSFET hybrid relays shown, IGBT versions are not suitable for switching audio, as they will introduce considerable distortion. As a hybrid, this will not be audible except when turning off under load. This is unlikely to cause problems.

Figure 3.3 - Possible Commercial Implementation For A Hybrid Relay

Commercial hybrid relays would typically use a PIC or ASIC (application specific IC) to perform timing functions, as this requires only a single IC and a bit of code to create the required delay. This could be expanded to include functions such as load detection (to verify the semiconductor(s) haven't shorted out), or other functions that the manufacturer deems worthwhile. None of this changes the basic operation, which as shown above is fairly straightforward. Even the smallest PIC will have more than enough processing power, but it may not be able to supply much output current to the optoisolator.

To show how the hybrid system works, the following timing diagram lets you see the process in detail. The relay 'on' time was deliberately kept to the minimum so both 'on' and 'off' sequences were on the same graph. The DC load power supply was 50V, with a 4Ω load. The simulation isn't perfect, as a real relay will show some contact bounce, especially when the contacts close, and I didn't add that as it would make the graph too busy.

Figure 4 - MOSFET And Relay Contacts Timing

Power is applied to the relay circuit exactly at the 1 second mark. The MOSFET starts conducting within a few microseconds, and this isn't visible at the time scale used. The MOSFET carries the load current until the relay contacts close (about 10ms). The MOSFET current is then reduced to almost zero - perhaps 100mA or so, depending on the relay and the MOSFET. When the relay 'on' signal is removed 50 milliseconds later, the MOSFET continues to carry the current until after the relay contacts have opened. This prevents any arc across the relay contacts, because the voltage across them is so low. The exact voltage depends on the MOSFET's RDS-On (about 0.18Ω for an IRFP240), so the relay contact potential will be only 2.25V for the examples shown here (4.5V with two MOSFETs in series). Either voltage is far too low to allow an arc to be created, which is the whole purpose of this scheme.

While this arrangement will always extend the total release time for the system as a whole, it's uncommon that there's a precise timing requirement for relay circuits. This is because designers know (or should know) that relays take time to activate and release, and while the specifications generally show very fast release times, this is invariably without the back-EMF suppression diode. The 'relays' articles show that the release time is usually extended to be roughly equal to the pull-in time when the diode is used, and it's very rare to omit it in any switched circuit. Deactivation can be made faster if necessary, as described in the 'Relays' [ 4, 5 ] articles.

Without the diode, the back-EMF from the relay coil can easily exceed 400V, and that will destroy most switching transistors. The design criterion that needs to be applied for a hybrid relay is based solely on the relay's worst-case release time, and the MOSFET must conduct for this time, plus a safety margin of (ideally) not less than 10 milliseconds. If it's known that all examples of the electromechanical relay release within 15ms (as an example only), then the MOSFET drive circuit should be arranged to ensure that the MOSFET conducts for at least 25ms after the relay drive signal is removed. This is easily achieved, even with simple circuitry.

In these examples, the timing is set by R1 and C1. To reduce the delay before the SSR section of the circuit is deactivated, simply reduce the value of either R1 or C1. With the other component values as shown, the delay time is approximately ...

t = R1 × C1 × 0.7

100k and 1µF therefore gives a delay of 70ms as seen in the timing diagram. I've shown C1 as an electrolytic capacitor, but a film cap is preferred for long-term reliability. R1 can be increased in value, but more than 220k is not advisable (and the positive feedback resistor [R4] would need to be increased to around 2.2MΩ). There is a great deal of scope for experimenting, and you can make changes as needed to suit your particular requirements. For example, if C1 is 220nF and R1 is 150k, the delay is about 23ms. This should be more than enough time for an EMR to release, but it must be verified!

Because there is an inevitable delay before a hybrid relay can release, they are not suitable where very fast circuit deactivation is a requirement. An example is a DC protection circuit for loudspeakers, as the delay may be sufficient to cause speaker damage before the DC is interrupted. As with everything in electronics, the end use must match the capabilities of the device(s) used.

I have included a TRIAC (bi-directional triode thyristor) and SCR (silicon controlled rectifier) hybrid relay for AC applications. Regardless of the type of hybrid relay, inductive loads may create problems if no form of protection against back-EMF is provided. This is sometimes easier with a MOSFET solution, because avalanche-rated MOSFETs are now readily available to handle an over-voltage condition. The same condition with a TRIAC generally causes spontaneous conduction - the TRIAC turns on due to the voltage 'spike', and will remain on until the current falls to zero, but this cycle may repeat. TRIACs have a rather odd terminal nomenclature, being 'Main Terminal 1' (MT1) and 'Main Terminal 2' (MT2). The gate (G) is adjacent to MT1. These are shown in Figure 5. TRIAC and SCR hybrid relays cannot be used with DC, as the TRIAC/ SCR cannot turn off.

Figure 5.1 - TRIAC Hybrid Relay

Because a TRIAC (or an SCR) will continue to conduct until the current falls to zero, by it's very nature the supply is always interrupted as the voltage and current (for a resistive load) falls to zero. This minimises back-EMF with reactive loads, but if the voltage and current are out-of-phase (inductive load), the TRIAC drive circuit needs additional components to ensure reliable turn-off. This is detailed in the MOC302x datasheet, and isn't shown in the circuit above. Consequently, Figure 5 is usable with resistive loads only. Unlike a MOSFET hybrid relay, the TRIAC circuit can be used only with AC. If the power supply is DC, it will turn on, but will never turn off until the supply is interrupted by other means. Note that the TRIAC shown is for convenience, and is one of many that can be used. The BTF139F-600 is rated for 600V (peak) and 16A RMS. R7 and C2 create a snubber that may be necessary with some loads. This is not covered here.

It's worth pointing out that if the AC load is inductive (a transformer or motor), you should never use a zero-crossing TRIAC driver (they are available). The worst case inrush current for inductive loads occurs when the supply is turned on at the zero crossing, so the driver must be a 'random' type, which turns on as soon as the required current is available, regardless of the AC voltage. Zero crossing drivers are better for resistive loads, as EMI (electromagnetic interference) is reduced.

Rather than a conventional TRIAC, the so-called 'snubberless' TRIAC deliberately inhibits conduction when the gate voltage is in the (often troublesome) 4th quadrant. This topic is outside the scope of this article, but there's some detailed information available in Project 159. STMicroelectronics has a TRIAC they call an ACST, which is a dedicated AC Switch with high immunity against ΔI/Δt commutation. Similar devices are known as 'Alternistors' or High-Commutation (Hi-Com) TRIACs, depending on manufacturer.

The best way to trigger an TRIAC is almost always quadrant 1 (MT2 and gate positive) and quadrant 3 (MT2 and gate negative). This is provided by default by the optocoupler. I leave it to the reader to explore the options.

Figure 5.2 - SCR Hybrid Relay

The SCR version is very similar to that used for the TRIAC, except that extra resistors (R7, R8) are required because the trigger current is lower. In addition, a conduction path is necessary for reversed polarities. The BT152-600R SCR is rated for 600V at 16A RMS (22A RMS with two for full-wave), and again is only a suggestion. Otherwise, performance is similar to that using a TRIAC. SCRs are available in higher current ratings than TRIACs, so this scheme is likely to be more common for high-current applications. SCRs are also less susceptible to the change of current vs. time (ΔI/Δt), which can cause spontaneous conduction with many TRIACs.

After deactivation, a TRIAC or SCR circuit will continue to conduct until the current half-cycle is complete, because they rely on zero current to turn off. This may extend turn-off time by a further 10ms (50Hz) or 8.33ms (60Hz). This applies to all TRIAC and SCR relays, hybrid or stand-alone.

The circuit can be simplified somewhat by using a 555 timer. There's a useful reduction of parts needed, and this may be appealing. With the values shown for timing (R1 and C1), the delay is about 43ms, so the EMR should have enough time to release (as the 'Relay' input is open-circuited or raised to 12V) before the electronic part is disconnected. Normally, a 555 timer expects the trigger pulse to be shorter than the delay, but we can use it to our advantage. The internal discharge transistor is replaced by Q1.

Figure 6.1 - 555 Timer Delay Circuit

As long as the input is held at +12V, the EMR is on and the timer can't start. The output will be high for as long as the EMR is powered. The timing starts only after Q1 turns off so C1 can charge via R2. The timer duration must exceed the EMR's dropout time. The optocoupler can be anything suited for the application, including the Si8752, MOC3022 or even a 4N28 or similar for a DC relay. The choice depends on the application, so it's left to the reader to decide.

This is probably the simplest (and cheapest) option, but it requires the user to understand the operation of 555 timers. Like the previous circuits, this one uses +12 to operate. The need for Q1 is a nuisance, but the 555 timer has to be used in an unconventional way to make a hybrid relay, and the transistor can't be avoided.

The next version shown here is also potentially useful, and uses a CMOS hex-inverter to perform the logic and timing. With one IC, two resistors and one diode, in terms of parts count it's lower than any of the others, although a 14 pin DIP IC isn't the smallest footprint around. It could also be done with an SMD IC, but would be a great deal harder to assemble.

Figure 6.2 - 4584 CMOS Hex Schmitt Trigger Delay Circuit

When the Relay input goes high, C1 is charged via D1 (1N4148 or similar), so the output of U1.2 goes low within a few microseconds. This causes the paralleled outputs of the remaining Schmitt triggers to go high, turning on the optocoupler. When the Relay input goes low, the EMR will release in the more-or-less typical time of 20-30ms, and C1 discharges through R1. Once the Schmitt trigger threshold is reached (around 45ms), the optocoupler is turned off and the 'solid state' relay section is disabled.

The circuit can also be made with an opamp instead of a comparator (a small parts saving), or there are some dedicated timer ICs that could be adapted for the purpose. Ultimately, you can use anything you like for the timer, provided it meets the primary criteria. It must activate the solid state relay instantly, and keep it engaged for at least 10ms after the EMR releases. Anything that you use must be tested thoroughly to ensure that it's 100% reliable. This is particularly important if your application involves switching DC at elevated voltage or current.

Figure 6.3 - Fully Discrete Delay Circuit

Some people like the discrete approach, so the circuit above is suitable. The circuit component values are only a guide, but with those shown it provides a 40ms delay. It doesn't have the accuracy of the comparator circuits shown in the reference designs, but it does use fewer parts and is easy to implement on Veroboard or similar. The transistor and low-power MOSFET are not critical, and can be anything you have to hand. The timing will vary with the gate-source voltage (VG-S) of the MOSFET, and the delay can be adjusted by varying R1. R3 raises the detection limit to a little over 2V to ensure better repeatability. Switch-off time is less than 1ms.

There are depressingly few timer ICs around to chose from - the 555 and its cousins turn up in almost every timer circuit you'll come across, and there aren't many other options. Despite the apparent complexity, a comparator based timer is one of the best - they are fast and very predictable.

While there's no reason not to use a PIC or similar microcontroller for the timing functions, for the most part it's a bit like using a sledgehammer to kill a mosquito. The timing function is very simple, and a 555 timer is the most economical choice. The amount of messing around with level-shifters and a 5V regulator make the idea of a microcontroller rather pointless, as you will end up with more parts and an IC that has to be programmed. A simple analogue timer can be 'programmed' with a trimpot if you think that's necessary. The code is trivial, but if you need to make an adjustment (to the turn-off delay for example) then the device has to be reprogrammed. I don't think it's worth the extra complexity, and it won't work any better.

With so many applications now using high-voltage DC (think electric cars for starters) it's useful to look at a DC only solution. One that caught my eye some time ago was a patent document from 1987 [ 7 ]. It's worth remembering that just because something has been patented that doesn't mean it's a good idea. It's somewhat sub-optimal in many respects, but the idea is interesting. The biggest problem with it is MOSFET dissipation after the mechanical contacts open, but careful capacitor selection will keep the conduction period short enough to prevent the MOSFET from overheating.

The MOSFET has high dissipation because it's operated in 'quasi-linear' mode. The capacitor creates a negative feedback path from the drain to the gate, so the MOSFET never gets a high enough voltage to create a 'hard' switch-on. As the voltage at the drain falls, so does the gate voltage. That means that the MOSFET can only ever turn on partway, so its dissipation is high. The 'worst case' dissipation is at at half the supply voltage (and therefore half the load current). For example, an 80V DC supply with a 10Ω load means the peak MOSFET dissipation is 160W. That may only last for perhaps 0.5ms, but it's not the way that MOSFETs are normally used. You must check the datasheet for the device you want to use to verify its safe operating area.

Figure 7.1 - 'Passive' MOSFET Arc Quench

A sample circuit is shown above, being the version I tested by simulation. A similar arrangement was also bench tested. The additional set of contacts is necessary if the DC source is liable to be turned on via a switch, and it prevents the MOSFET from turning on if a voltage 'step' occurs. When the relay opens, the MOSFET gate voltage will only ever get to somewhere from 4.5V to 6V (depending on the MOSFET itself), so the MOSFET is in linear mode. Selecting a MOSFET with very low RDS-on is a bad idea for a MOSFET operated (even momentarily) this way, so you need to be fairly careful with your choice.

The circuit is shown with a ground connection for the activation and switching sections. However, they are completely independent and can be used with any voltage between the two sections that's within the isolation voltage rating for the relay. Like any other relay, the contacts can be at any (sensible) voltage, as can the control circuit. C1 must be rated for the DC voltage used, and it would be sensible to use a Y-Class cap as they have a very high voltage rating and are 'fail safe'. If C1 were to become shorted, the MOSFET will be 'on' permanently.

This circuit can be used with either 'high-side' switching (as shown) or 'low-side' switching. The latter means that the load is connected directly to the supply, and the hybrid relay is connected to ground. This makes it suitable for a wide range of switching options. It can even be used with a negative supply, provided that the correct polarity is maintained. With a negative supply, the MOSFET's drain must be positive with respect to the source.

Figure 7.2 - 'Passive' Circuit Waveforms

The waveforms are shown above. The red trace is the relay control voltage, but it does not show the inevitable delay when the voltage is removed. This is dependent on the relay itself, and with a more-or-less 'typical' relay and a modified back-EMF circuit (R1 and D1) it will release the contacts in about 4ms. At the instant the contacts open, the drain voltage increases rapidly, and the rising voltage is passed by C1 to the gate of Q1, turning it on. The gate voltage is shown in the brown trace. As you can see, it never reaches the voltage needed for full conduction.

It's important for any hybrid relay to have a delay that's sufficient to allow the EMR's contacts to separate widely enough to be below the arc initiation voltage. A 'safe' assumption for air at sea level is around 1kV/mm, so if you have a voltage of (say) 500V, the absolute minimum contact separation is 0.5mm. Most compact relays have a separation of around 0.4mm, and this will prevent an arc if the voltage is static, but not if the contacts open with DC applied. A common (10A/250V AC, 30V DC) relay has a maximum DC voltage of 30V at rated current. If this is exceeded, a sustained arc can be created that will melt the contacts and often the entire contact assembly as shown in the photo at the beginning of this article.

The original patent document also shows an AC version, but I've not included it because (IMO) it's unsuitable for general usage. It's certainly possible, but one of the other techniques described above is a far better option because they are fully controlled and provide full MOSFET conduction. The delay is also adjustable, and the MOSFET is turned off very quickly, something the arrangement shown in Fig 7.1 cannot achieve. It's inevitable that the MOSFET will always have very high dissipation as it turns off, and the time this lasts is critical. Dissipation is greater than 50W for 1.5ms, which isn't a disaster, but it's longer than is desirable.

For example, 1kW for 1µs is fine, but 1kW for 1ms is not a good idea at all. Have a look at the SOA (safe operating area) curves for any MOSFET, and you'll see that they are capable of extraordinary dissipation if the time is short enough. The SOA curve for the IRFP460 shows 500V (VDS) at 50A for 10µs - that's an instantaneous (single pulse) dissipation of 25kW! If the time is extended to 1ms, the maximum single pulse dissipation is reduced to 2.25kW. That's still a lot of power, so it's not a serious limitation.

I decided that it was worth testing the Fig 7.1 circuit, because it's easy to do and I have a test relay set up to run tests for arcing and other 'interesting' things. My first test has a much shorter time-constant for C1 and R2, and the MOSFET couldn't conduct for long enough for the contacts to be far enough apart to prevent an arc. Needless to say a nice fat arc was produced. I increased the value of R2 to that shown, and it worked very well. However, it's not entirely without issues. If the relay is turned 'off' then back 'on' very quickly, C1 doesn't have time to discharge and an arc resulted. The secondary set of contacts will prevent that, and they also ensure that nothing can turn on the MOSFET unless the main contacts are opening.

All-in-all, I would describe this circuit as interesting, but it's limited to DC and the need for the second set of contacts has been demonstrated. I used a test voltage of 90V (78V when loaded to 4.85A) and it does stop the arc. However (and unlike the other circuits shown here), contact bounce is not suppressed. The MOSFET turns on and off during the bounce period because it relies on the sudden increase of voltage when the contacts open, and there isn't enough time for C1 to discharge between 'bounces'. IMO, while this circuit works, it is sub-optimal in too many respects to be truly useful. However, it does work 'well enough' to make it worth considering for simple switching that isn't

Figure 7.3 - Alternative 'Passive' MOSFET Arc Quench

The circuit shown in Fig. 7.3 was contributed, and is a very good alternative to that shown in Fig. 7.1. There is one difference though, in that the Fig. 7.3 version will only work when the load is ground-referenced. It is exclusively a low-side switch. The advantage over the Fig. 7.1 circuit is that when power is applied (with a high rate-of-change), the MOSFET doesn't conduct momentarily, and the second set of relay contacts isn't needed.

(Fig. 7.3 Submitted in 2024 by H. Paul Robinson)

How it works may not be immediately apparent. When the relay is turned on, C1 is charged to the supply voltage via D2 and R3 because the MOSFET's source (along with the anode of D2 and R2) is raised to the full supply voltage. The peak charge current is limited by R2, which can be reduced to as low as 100Ω. When the relay turns off, the charge on C1 turns on the MOSFET. This will occur when the voltage across the relay contacts exceeds around 5V. As with the other versions shown, the MOSFET conducts and means that the relay contacts only 'see' a peak voltage of around 10V, well below the voltage needed to create an arc. The MOSFET 'on' time can be increased by using a higher value for C1, but I wouldn't exceed 100nF unless the voltage is quite low (e.g. ~35-40V).

This scheme is very similar to the 'bootstrap' connection seen on high-side MOSFET drivers and PWM (Class-D) amplifier ICs. It allows the MOSFET gate to be driven above the drain voltage, but only during switching. There is an inevitable voltage drop, which depends on the MOSFET itself. During the turn-off process, the gate will typically be around 5V above the source voltage.

If you happen to be a relay manufacturer (in this case, Omron [ 8 ]), then you can build a 'special' relay, with extra contacts arranged to operate slightly differently from the main (current-carrying) contacts. This lets you simplify the design quite dramatically. The RL1a contact must close first, activating the TRIAC. A fraction of a second later, the main contacts (RL1b) close, and take up the load current. The TRIAC turns off, because it has almost no voltage across it. When the coil voltage is removed, the main contacts should open first, and the TRIAC takes over until the voltage falls to zero. The TRIAC then turns off.

Figure 8.1 - Commercial AC Hybrid (Omron G9H Series)

There's a snubber (R3 and C1) to ensure that the TRIAC does turn off with difficult loads, along with a varistor to limit inductive spikes. I'm sure that a fair bit of engineering has gone into this design, but as a user, you pay for it. I checked the price, and they are around AU$175 each (priced in 2023). You can build your own for a small fraction of that.

Unfortunately, we can't build our own specialised contact set, so the circuit becomes more complex. However, the parts needed are mostly fairly cheap, and the circuitry isn't complex. Mostly, you'd select the simplest possible circuitry unless you have a specific requirement for very predictable timing - at least within the normal range of commonly available relays.

This article is intended as a primer on hybrid relays, and there are many considerations that need to be considered for a 'real-world' application. As with many ESP articles, it's provided to give information that can be used for your own designs. Timing, relay, MOSFET and/ or TRIAC selection depend on the application, and the information here has guidelines, rather than complete 'ready-to-go' designs. While the circuits shown will all work, it's up to the end-user to determine the power components, based on the final requirements of a system.

The disadvantage of a hybrid relay is that it uses semiconductors. While these make the idea possible, they are also a point of failure. Most semiconductors will fail short-circuit, so the relay will never turn off, and this can place operators and/or anyone else at risk. A hybrid relay should never be used in a safety-critical application, and extensive testing is always necessary to ensure that all parts will not be subjected to voltage or current beyond the ratings of the devices used.

The circuits (and results) described are simulated, but have not been built and tested. This is not a limitation in any way, as the fundamental principles are easily established, and a simple 'thought experiment' is all that's needed to verify that operation is exactly as described. It's possible that at some stage in the near (or not-so-near) future that I will test (some of) the circuits, and the MOSFET relay based on the Si8752 has already been built and tested, and is described in the MOSFET Relays article and as Project 198. Indeed, it was a result of running tests on the prototype board I made that prompted this article.

One specification that is almost never provided is the contact clearance within any electromechanical relay. In most cases, it's a great deal smaller than you might expect. One of the few relay datasheets I have that even mention this parameter is for an automotive relay (nominal voltage 14V, switching up to 40A), and the contact clearance is stated to be 0.4mm. That isn't very much, and I dismantled a relay that I'd been using to test the static contact welding current and measured 0.4mm clearance (shown in the photo at the top of this page). This is an almost identical relay to that shown in the Figure 1 graph, rated for 30V DC and 250V AC, at 10A. In case you're interested, the NC (normally closed) contacts welded themselves together with 50A AC, and the relay wouldn't operate until I applied 24V to the 12V coil. The lesson from this is clear - don't exceed the rated current!

The three articles on relays [ 4, 5, 6 ] are worth reading if you haven't done so already. A vast amount of research went into the compilation of those, and they provide more information than you'll find almost anywhere else. While these common components appear to be simple, like most 'simple' parts they are far more complex than you imagine. None of it is hard to understand, but there are things that you won't find in most 'blogs' - including those from manufacturers. Knowing the limitations is very important to ensure reliability.

It is possible to buy hybrid relays, but expect them to be seriously expensive. If you need one, the DIY approach will most likely save you a considerable amount of time, effort and (probably) money as well. You can use an EMR and MOSFETs (or SCRs, TRIACs, etc.) to suit your application. In one on-line article I saw, the process has been taken to extremes using an Arduino for control. This is basically a silly idea, as it makes the end result far more complex than it will ever need to be for a practical circuit. Even turning off an optocoupler's LED while the EMR is engaged (to minimise lumen depreciation) can be accomplished with (very) simple timers if you wanted to go that far.

Reference 6 is particularly useful, as it describes 'solid state' relays (SSRs) in detail, including the advantages and disadvantages of each type. Most aren't suitable for audio, other than a MOSFET relay.

Main Index

Main Index Articles Index

Articles Index