|

| Elliott Sound Products | Project 227 |

![]()

![]() PCBs may be made available for this project depending upon demand.

PCBs may be made available for this project depending upon demand.

Main Index Main Index

|

Projects Index Projects Index

|

Project 198 describes a MOSFET relay using the Si8752 isolated MOSFET driver. This is a great solution, but the availability of the Si8751/2 devices is still a little patchy. With any amplifier with greater than 35V supplies, the risk of a standard electromagnetic relay (EMR) arcing across the contacts is very high, and while the Project 33 speaker protection project shows how to wire the relay properly, high voltages are still a big problem. I have described hybrid relays in an article, but the descriptions are generalised.

The hybrid relay described here is designed specifically to be used with Project 33, but it can be used almost anywhere that a hybrid relay is required. The circuit needs a dedicated 12V supply, and if used with P33, that doesn't use the amplifier's positive supply rail. There are a number of ways to get the 12V supply, and these are described below. One thing that's important is to minimise the time the speakers are subjected to DC from a failed amplifier. There's an inevitable delay caused by the P33 itself, and this is unavoidable. The design shown here specifically targets the relay drop-out time, and rather than using MOSFETs to handle the full speaker current in use, that task is handled by an EMR. Arcing is prevented by keeping the MOSFET relay section 'on' for a preset time after the DC to the EMR is removed.

The isolation device selected for this project is a 'PVI' - photo-voltaic isolator. There are several to choose from, but only a few are recommended. These devices are made by several manufacturers, but to be useful they must have an internal 'turn-off' circuit. Without that essential add-on, they become a nuisance because you have to add extra circuitry. By their nature, PVI optocouplers have very limited output current (less than 20µA) and a limited 'on' voltage. Most can manage about 9V (open-circuit), which is just enough to drive the MOSFET gates.

Note: This project is aimed at experienced constructors. You need to know how to use an oscilloscope, and be fully aware of the static sensitivity of MOSFET gates. If you use a PC sound card in place of an oscilloscope (to test relay release time), you'll need to make attenuators (or an adapter) so the sound card isn't damaged. ESP accepts no responsibility for errors you may make that cause damage to any equipment. By continuing to read this article, you accept all responsibility for damage howsoever caused.

The circuitry described is not difficult to understand, but you must run proper tests on the completed circuit to ensure that the MOSFETs maintain conduction until the relay contacts are open. A test procedure is described, and it requires the use of an oscilloscope to verify operation. I don't recommend this project for anyone who doesn't have a scope and/or doesn't know how to use it properly. In particular, you must know how to use the scope in 'single-shot' mode, to capture the instantaneous readings as shown below.

The task of detecting the fault DC is handled by the P33 board, and the hybrid relay circuit prevents contact arcing. Since the MOSFETs are not expected to handle the programme material, there's no need to use anything 'exotic', as they only have to handle either audio or DC fault current for a few milliseconds. Because the relay contacts open with only a small voltage across them, there is no possibility of arcing. Unlike a dedicated MOSFET-only relay, there's no need to select the MOSFETs for very low dissipation, as they will only be fully active for a short period. Even if they dissipate a peak power of 1-200 watts with fault current, it doesn't matter because the period is so short.

It's a bit of a challenge to know just how long the MOSFETs need to conduct. If the MOSFET relay were to turn off at the same time (or before) the EMR's contacts open, the whole point of the exercise is lost, the relay contacts will arc, and speakers may be destroyed. I tested the relay I recommend for P39 with a 'fast turn-off' modification, and found that the contacts release in under 4ms. I tested this extensively, and it never varied. Based on that, I figure that the MOSFET relay only needs to extend the switching time by about 10ms. I strongly recommend that you run a test for the relay you intend to use (see Relay Testing below).

The EMR will be a 1-Form-C type - single-pole double-throw (aka changeover). It needs to be able to handle the normal audio current. Assuming that the amp will not be driven into hard clipping for extended periods, the current rating can be estimated from the supply voltage (positive or negative) and the speaker impedance. The worst case will be ...

IRMS = VS / ( Z × √2 )

In reality it will be less (often a great deal less), but a safe assumption is that the continuous current is half that calculated. This provides a good safety margin for normal programme material. With an amp using ±56V supplies and a 4Ω load, the relay should be rated for not less than 5A, but in general a 10A relay is the minimum I'd recommend. The DC fault current is VS/ZDC but that will only be present for a very brief time. The MOSFETs must be able to handle the full fault current (about 16A for the example given). The ability for the MOSFETs to handle the instantaneous voltage and current is critical, as failure removes full protection (the EMR contact wiring provides some 'backup' protection). If the relay contact current is significantly more than the datasheet rating, there is a risk that the contacts may weld together.

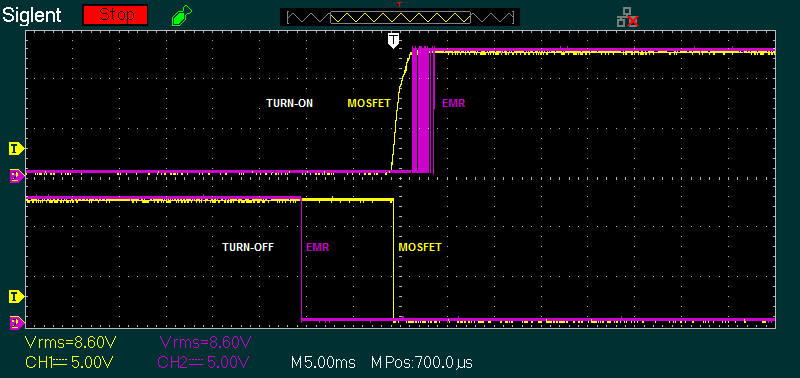

Figure 1 - Relay Coil Voltage And Opening Time

I tested the relay I suggest for both P33 and P39 (mains soft-start), but rather than using a diode in parallel with the 12V coil, it had the diode in series with an 820Ω resistor. This causes the large negative peak seen at the instant that power is removed. However, it also allows the relay to release much faster than it would with the diode directly in parallel with the coil. As shown in Fig. 1, the contacts open in 3.8ms, which extends to about 7ms with the diode only. The contact closing time is around 6ms after power is applied (workbench tested). The voltage spike is due to the resistor as it absorbs the coil's back EMF. The coil resistance is 260Ω so the voltage peak is -37V. This can be worked out easily if you want to ...

VP = Rpar / Rcoil × Vcoil

VP = 820 / 260 × 12 = 37.8V

I've described this little 'trick' before, and it's very effective. The diode in series with the resistor (D1 in Fig. 2) isn't strictly necessary, but it prevents the resistor from dissipating power when the relay is activated. Without the diode, the resistor will pass 14.6mA and dissipate ~176mW. It's not much, but it's more current that has to be provided by the power supply, and it's doubled with two relays. Because of the way the final circuit is wired, the relay gets the full 12V when the input is taken high. I verified that the contacts close within about 4ms, and most relays of the same ratings will be similar.

The circuit is a modified version of the hybrid MOSFET relay shown in the 'Hybrid Relays' article. The IRF540N MOSFETs are rated for 100V, have RDS-on of 44mΩ and a maximum current of 33A (continuous). They are 130W devices, and will remain within their safe operating area (SOA) with a supply voltage up to 80V and a 4Ω load. The photovoltaic optocoupler is shown as a APV1122 (DIP), but you can also use the PVI5080NP (DIP), TLP3906 or VOM1271 (the final two are SMD only). These ICs are not particularly expensive, at around AU$5 - AU$7 each. There are a few others, but they don't have an internal 'turn-off' circuit. If it's not internal, it has to be added externally which is a nuisance. A turn-off circuit is shown below, using a cheap JFET and a resistor.

The timing circuit can be changed by altering the value of R6. If your relay opens slower than those I tested, increase the value of R6. If it's doubled, so is the time delay. It's doubtful that you'll need to go above 150k, but see Relay Testing to determine the drop-out time for the relay you use. The transistors at the input are needed to obtain the right polarity for P33, and to make sure that the relay 'fast-release' circuit (RL1, D1 and R6) works as intended. The first transistor reverses the polarity of the control signal to suit the 555 timer. The timing for U1 is determined by (approximately) ...

t = R6 × C1

t = 120k × 100n = 12ms

The formula is not the 'standard' one for a 555 monostable because it's being used differently from the traditional 555 circuit. The front-end level converter and relay drive transistors modify the behaviour slightly, and also change the timing period. The error is small and not worth worrying about. The component values have been chosen to use the minimum number of different values, while ensuring that there's plenty of current available where it's needed..

Figure 2 - Hybrid Relay Circuit Diagram

The zener diode (D3) is shown as 'optional', and it protects the MOSFET gates. I consider it to be essential, as it prevents static damage. During tests, the loading of a 'typical' multimeter will reduce the measured voltage a little, but it's not a problem. You should get at least 7V between the common source and gate connections of the MOSFETs (positive to the gate). The normally closed (NC) contacts on the EMR are not used. Normally, these contacts would be grounded, but you can't do that when the MOSFET relay section is included.

The turn-on time for the MOSFETs is slow, but that doesn't matter because the EMR carries the audio when the relay is activated. Because the MOSFET relay section is shorted by the EMR contacts we don't have to be concerned with MOSFET dissipation during normal use. The MOSFET relay is only active (for ~10ms as shown) when the hybrid circuit is powered off, either by removal of the 'Relay' voltage or when overall power is removed. You can work out the time it takes for the PVI's output to reach a given voltage, knowing the capacitance and output current. For example, if you want 7V at the gates of a pair of IRF540N MOSFETs (input capacitance [Ciss] 1,960pF each) and the PVI provides 10µA ...

t = C / I × V

t = 3,920pF / 10µA × 7V = 2.74ms

That's not fast by any stretch of the imagination, but it's still faster than the relay. I tested a PVI with 8.2nF of capacitive loading, and got 7.5V within 2.5ms, so 'real life' may be a bit better than the datasheets claim. One thing that affects the turn-on time is the non-linear behaviour of the gate voltage when it's provided by a high impedance source. As the MOSFET(s) start to turn on, there's feedback provided by the internal drain-gate 'Miller' charge (Qgd). This puts a 'kink' in the voltage curve, with a plateau at the initial conduction voltage. The width of the plateau depends on the value of Qgd, which is 21nC (nano-coulombs) for the IRF540N. Fortunately, this isn't a major factor in this application.

The activation sequence below doesn't show turn-on. With a P33 circuit in control, if there's a DC fault at power-on the relay won't activate at all. The MOSFET section is used only to prevent EMR contact arcing when/if the relay releases with a DC fault present. The relay contacts should be rated for the full RMS current the amp can deliver. In most cases 10A relay contacts will be fine, but with a higher output current (e.g. >56V supplies with a 4Ω load) you may need to use 16A or 20A contacts. The worst-case scenario is if the DC fault current is so great that it partially welds the relay contacts. While this is possible, it's unlikely in practice if the relay is sufficiently robust.

Figure 3 - Relay Activation Sequence (Simulated)

Power is removed from the relay coil at 1.01 seconds, and the simulation allows a drop-out time for the EMR of 4.6ms. At that point, the MOSFETs carry the full current for 7.9ms, long enough for the contacts to be fully open, and then they switch off. There can be no arc, because the relay contact voltage is next to nothing. The MOSFETs are still a critical part of the circuit though, because a failure means there is no speaker protection. Semiconductors fail short-circuit by default, so if a MOSFET fails it can pass DC through to the speaker. It depends on which one fails and the polarity of the DC fault current, but it's wise to use MOSFETs with a current rating that covers the worst case, plus a bit extra for good luck.

The MOSFET power rating doesn't need to be particularly high, because the dissipation will usually be less than 5W, and that only lasts for less than 10ms. This means that a heatsink will not be necessary, even for a very high-powered amplifier. There will be a very high (but very brief) dissipation 'spike' as the MOSFETs turn off. This can exceed 200W, but it shouldn't last longer than 100µs. This is well within the IRF540N's 1ms SOA curve. The MOSFET voltage rating must be greater than the supply voltage, and 100V MOSFETs will allow up to ±80V supplies - 400W into 8Ω or 800W into 4Ω. If the supply is greater than that, then naturally the MOSFETs also need a higher voltage rating. The maximum current is for IRF540N MOSFETs is 20A (4Ω, 80V), so a MOSFET rated for 30A or more will be fine for high supply voltages

The PVI was selected as the preferred solution because it removes the requirement for a floating power supply. It's certainly possible to use either a MOSFET relay IC or a standard optocoupler, but either of these need a floating power supply which is irksome to include. To make matters worse you need two - one for each MOSFET relay circuit. I did consider this possibility, but I decided against it as it just complicates everything. A separate project will be produced shortly that shows how it can be done, but it's less than ideal.

PVI devices (like all semiconductors) are temperature-sensitive. At high temperatures, the photodiodes become leaky, and the output voltage and current is reduced. The LED should be operated at the lowest current that provides good switching for the MOSFETs (I aimed for ~10mA), and the IC should be kept away from anything that runs warm or hot.

Figure 4 - Timer & Hybrid Relay

There are a few minor value changes that are important if you plan to use a single relay driver circuit for two channels. The 555's output can go to another 1k resistor and PVI IC, and Q2 should be a BC640 if you want to drive two relays in parallel. The cost of the parts saved is small, but there's less space needed if the 555 and associated parts aren't duplicated. R5 should be reduced in value if there are two relay coils in parallel. I suggest about 470Ω, which will provide the same relay drop-out time with a pair of relays in parallel.

The drawing shows how to use a single timer with two separate hybrid relays. It the same as shown in Fig. 2 (other than the two changes referred to above), and the two sections have been separated for clarity. It's theoretically possible to drive more than two hybrid relay circuits, but the 555 timer will start to run out of current, and for loudspeaker protection it's unlikely that anyone would want to use more than two anyway. For multi-channel systems, each stereo pair would normally have its own protection circuit.

If you use a PVI that does not have an internal turn-off circuit, one must be added. Without it, the gate capacitance of the MOSFETs will keep them turned on for far too long, and turn-off will be very slow and it will cause speaker damage and probable destruction of the MOSFETs due to excessive dissipation. IMO it's far better to pay a bit extra for the PVI than to have to mess around with the following circuit (or something similar). Note that the circuitry is all very high impedance, and you will almost certainly have to select the JFET for minimum gate-source cutoff voltage (VGS-off). For the J113 it can be anywhere between 0.5V (good) to 3V. If the VGS-off is greater than ~1.2V it's useless in this role. See Designing With JFETs for information on how you can measure VGS-off.

Figure 5 - Turn-Off Circuit Using JFET

The datasheet for the VOM1271 shows a turn-off circuit using a P-Channel JFET. This is less convenient, because while all JFETs are now somewhat limited, P-Channel types are even less common than N-Channel. An external turn-off circuit also reduces the gate voltage for the MOSFETs, and the available voltage from PVIs is already only quite low (typically around 9V). It's possible (but adds even more parts) to use a standard optoisolator (e.g. 4N25, LTV817, etc.) to create a turn-off circuit, but the added circuit complexity is unlikely to win any friends.

The next part of this arrangement is the power supply. You can use a small buck converter to reduce the amplifier's positive rail voltage to 12V, but those you can buy cheaply only allow a maximum of around 40V or so. These are convenient, and are generally suitable. A 40V (max.) input adjustable buck converter is shown in Project 220, but it's probably cheaper to buy one than build it yourself. This is somewhat depressing, but if you do build one, you'll know a lot more about how it works than if you buy it ready made.

Figure 6 - Buck Converter (Typical)

If you use a DC-DC converter, the one pictured is typical. These are cheap (under AU$10 each), and can operate directly from the +35V supply used for P3A for example. If the voltage is greater than 35V, then it can be reduced by using a zener diode in series with the incoming supply. Because it's a switching regulator, the input current will be less than the output current. For a maximum output current of (say) 150mA, the input current will be about 70mA from a 35V supply. If a higher voltage is reduced by zener diodes, aim for an input voltage between 30-35V, and select zener diodes to suit. Three 6.8V zeners in series will work fine for a 56V supply, and they will dissipate about 450mW each. Alternatively, use a simple pre-regulator (1 transistor, 1 resistor & 1 zener diode). Allow for up to 100mA to the DC-DC converter.

The other alternative is a switchmode supply such as that shown next. This was a commercial plug-pack (aka 'wall wart') that was pulled apart and the mains pins cut off. Two holes are drilled in the end for the mains input leads, and when the DC leads are wired and the PSU installed, the lid is snapped back on. The case has plenty of room (and electrical clearance) for mounting screws in the base. The supply is rated for 12V at 1A, so it can power the P33, hybrid relays and still have enough reserve to power a mains soft-start/ inrush limiter (such as Project 39).

Figure 7 - AC-DC Power Supply From Plug-Pack

This is a suggestion I've made for a few projects, and it's also shown (in a different enclosure) in the article about flyback SMPS (see Off-Line Flyback Power Supplies). Provided you get a supply that's fully approved for your country, it will be safe and (hopefully) reliable. It's very important that you get a supply that has safety agency approvals, as far too many 'cheap' PSUs are cheap because every possible corner has been cut. They may radiate excessive interference, and in some cases they can be deadly.

When you have the power supply of your choice sorted, you can look at the overall wiring scheme. As noted earlier, for loudspeaker protection you'd use P33, and the connections are shown next. While it's possible to use a DPDT (double-pole, double-throw) relay, it's hard to recommend because it will lead to a mess of wiring and it's easy to make a mistake. However, the control circuit doesn't have to be duplicated.

Figure 8 - P33 Wired With Two P227 Hybrid Relays

The P33 is still the heart of the circuit, and it provides a power-on mute, DC detection and power-off muting as well. Instead of driving relays directly, the P33 powers the EMRs and the MOSFET relay circuit, with each relay module being a separate entity. With the standard P33 input filter using 100k and 10µF, a 35V DC fault is detected in about 27ms for a positive fault, and 34ms for a negative fault. A higher voltage results in a shorter detection time, 20ms and 25ms respectively. The circuit has proved itself on many occasions, and it's also been subjected to rigorous testing.

If P33 is to be used with the hybrid relays described here, there are a couple of minor modifications. R12 (10Ω) should be replaced with a link, and C4 (10µF) should be increased to 22µF. Q4 is a BD140, but you can use a BC556 (note that the pinouts are quite different). D9 isn't necessary and can be deleted from the BoM. The remainder of the circuit is unchanged.

If you use an unknown relay, it should be tested to measure the time it takes to open. This isn't hard to do, but it requires a 2-channel oscilloscope that can perform a triggered single-sweep. One channel of the scope is connected to the relay contacts, and the other to the coil (with the back-EMF protection circuit shown). You need a switch to disconnect the relay, and trigger on the negative slope of the coil. You are going to duplicate the measurement shown in Fig. 1. The channel settings (and colours) are those used by my scope, and are the same as shown in Fig. 1 above.

If you don't have a scope you can use a sound card based scope interface such as that shown in PC Oscilloscope Interface. While a PC sound card has limited response, it should be able to handle the timing expected of a relay. A simplified version of the interface can be used - it can be done with only a few resistors. If you can't work out how to do that, you don't have enough experience to build this project. A sound card is not DC coupled, but you'll still be able to see the transitions. Getting a 'single shot' trace isn't possible with most PC-based oscilloscope software, so you may need to capture the waveforms using Audacity or similar, and use the cursors to measure the timing. Fiddly, but it can work well enough.

Figure 9 - Measuring Relay Release Time

When the scope triggers, you should get two traces - one of the coil voltage collapsing, and the other of the voltage on the normally open contact. The sweep speed should be about 1ms/ division, and the channel voltages set as seen in Fig. 8. The time difference between the coil voltage and the contact output voltage changes show the release time (t-release). Run the test several times to make sure that it's consistent. You may need to adjust the timing of the Fig. 2 timer to ensure it's at least 5ms greater than the relay's release time.

Unfortunately, there's no other way to perform the test, as multimeters are far too slow, and even LEDs can't be used because you can't see a ~4ms difference with any reliability (if at all). The release time will typically be somewhere between 4ms and 10ms, but you should check the datasheet for the device you intend to use. Using the 820Ω resistor improves release time by up to 50%, depending on the mechanical design of the armature and the coil resistance. You can use other values, but as the value is increased, so too is the negative voltage. It must be lower than the VCEO for the transistor (-65V for the BC556). The total voltage is the supply voltage plus the negative spike (49V for the example shown).

It's possible to reduce the relay's release time further by using an 'efficiency' circuit (a resistor in parallel with a capacitor, in series with the coil). I tested this and was able to reduce the release time to 3ms, but that's academic when we know that P33 has an in-built delay (which must exist) that may take 30ms to operate. Saving one millisecond by speeding up the relay doesn't help at all, and it uses more parts.

I built my prototype on Veroboard, but in this instance I didn't try to make it as compact as I generally would. The relays (EMR and MOSFET) are on the right, with the 12V input at top centre and ground at bottom centre. The input is on the left, and just behind the two MOSFETs is the jumper that allows me to separate the two 'relays' to allow me to run the test shown in Fig. 11. I included the zener diode, and its leakage caused no problems, even with the limited current available from the PVI.

Figure 10 - Prototype Veroboard Test Unit

The prototype was built to the circuit of Fig. 2, with the only change being that I used a 2k resistor for R7 to reduce the PVI's LED current. The only jumpers below the board are between pins 2 and 6 of the 555 timer, and around the EMR's contacts (the pin spacing is not at 2.54mm [0.1"] intervals). Normally (and as suggested earlier), the relay would not be mounted on the board, as it takes up a lot of space and limits the relay to that for which the board was designed. For the test unit it was more convenient to have everything together to save on external wiring.

This is an easy circuit to test, even though it uses two different switching systems - the EMR and MOSFET relay. You don't have to test it with high voltages or currents, but you do need to be able to differentiate between the EMR contacts and MOSFET conduction. This is done by using a separate resistor for each section. The supply voltage for testing can be the 12V supply used for the hybrid relay circuit or an external power supply capable of around 30V at 1A or more. I've shown an external 15V supply, but you can use whatever you have handy. The test voltage should be less than 30V though, otherwise the EMR contact may arc without the MOSFET relay connection. The current should be 'reasonable' - 150mA is pretty safe. The total current is 300mA when both sections are on.

Figure 11 - Test Setup (Requires An Oscilloscope)

With a separate resistor from the relay contacts and the MOSFET relay, you can see the exact time that each turns on and off. You can't do this without an oscilloscope, because you need to be able to observe the presence (or otherwise) of voltage across the load resistors. Because the EMR and MOSFET relay are isolated from each other, you just open the link between the COM (common) contact of the EMR and the drain of Q4. A separate load is used for each, and around 100Ω is ideal. Make sure that the load can handle the power (P=V²/R).

When the switch is turned on, both loads should show a voltage almost exactly the same as that from the test supply. When the switch is turned off, the voltage across 'Load1' should drop to zero after a few milliseconds, followed by the voltage across 'Load2' about 7-10ms later. If you get this, everything is working as it should. To be 100% certain that both MOSFETs are working, reverse the polarity of the test PSU and verify that you get the same response.

Remember to re-join the link between the EMR 'COM' contact and the drain of Q4 when you've finished testing.

Figure 12 - Test Measurements For Prototype

I took measurements from my prototype circuit using the method shown in Fig. 11, with two captures combined into a single image. The MOSFET section turned on (slightly) faster than the EMR, so all contact bounce (the 'fuzz' on the upper violet trace) will be shorted. The delay between the EMR and MOSFET relay release is quite obvious at about 10ms, which is a little longer than the calculated figure. The measurement shows the difference between the EMR and MOSFET relay, not the full delay of the MOSFET relay. R6 (Fig. 2) could be reduced to 100k or even 82k, and still provide protection. For the test, I used a lower current for the PVI, at about 5mA. This was done so I could create a 'worst case' test circuit. Otherwise, the circuit performs exactly as expected.

The relay I used was tested for contact resistance, using a current of 1A and a true 4-wire measurement. The NO contacts measured 6.5mΩ and the NC contacts measured 10.5mΩ. The NC contacts are not used, but it was easy enough to run the test. The difference is normal, as the NC contacts are held closed by a spring that has to be weaker than the magnetic pull of the coil and armature. For reference, I also tested a similarly sized 12A relay, and measured 1.9mΩ (NO) and 2.2mΩ (NC). During normal programme material the MOSFET conduction is minimal (~74mA/ A for 88mΩ total MOSFET RDS-on).

The final test was performed with a 78V (loaded, 90V unloaded) DC supply and a 16Ω load, so 4.875A DC. I know from other tests that this voltage and current will create a destructive arc even with 1mm contact separation, and the relay I used only has a 0.4mm contact gap. The circuit broke cleanly every time, and even after repeated tests the MOSFETs never got more than a couple of degrees above ambient. I consider this to be a success.

This is a circuit that you will find only on the ESP site, or at least until such time as some turd steals it. Along with the Hybrid Relays article, the info I've provided is the most complete you'll find anywhere. There is almost nothing else that describes the design and operation for anything other than EMR+TRIAC hybrids, and the little that's available has minimal technical details.

While the additional circuitry may appear a bit daunting, it's all quite simple in reality. Depending on interest, I may make a PCB available that has the necessary drive and delay circuits on-board, but for maximum flexibility the electromechanical relay(s) will likely be off-board. This is the approach taken with P33, and it means that you don't have to use the specific relay that the PCB is designed for. This is important, because sometimes the relay will have to be fairly large (electrically and physically) for high power amplifiers. A board that can only take a 10A relay isn't much good if you need 20A.

It is possible to make the circuit detect the relay release by monitoring the negative voltage. I elected not to do so as the detection circuit is fairly complex, and it has to be adjustable. You still need to run tests, but the results are likely to be more ambiguous than the simple timer. With a circuit that's designed to provide protection, it must be reliable. It will do nothing 'useful' - possibly for its entire life, so being 'clever' isn't actually very clever at all.

Overall, I'm rather pleased with the results, which have been simulated and bench-tested. While the simulations I ran tell me that it should work as expected, the bench test tells me that it does work as expected, and I have run real-life tests that would destroy the EMR by itself. While the circuit is shown as a speaker protection circuit, it isn't limited to that. It's a true hybrid relay that can be used for switching high voltage DC (only one MOSFET is required) or other 'hostile' voltages. I do not recommend using it with mains voltages. That would require very good isolation between the control and hazardous voltage sides of the circuit, and although relays and PVIs are rated for mains usage, a Veroboard layout is not!

Remember that hybrid relays are not suitable for safety isolation. If used with mains voltages, it's a project for experienced constructors only!

All references are shown in-line, other than the datasheets for the various PVIs mentioned. The datasheets for a number of MOSFETs were also checked, primarily to get an idea of the 'typical' gate capacitance that has to be charged from the miserly 10µA or so available. All technical references are ESP articles, as no-one else has published anything with the same level of detail on the subject.

Main Index Main Index

|

Projects Index Projects Index |