|

| Elliott Sound Products | Dangerous Plug-Packs |

Main Index Main Index  Articles Index Articles Index |

When one goes online to find a plug-pack ('wall-wart') power supply (aka PSU - power supply unit) either to provide power for a project or charge their phone, it's not at all unreasonable to expect that it meets regulatory requirements for electrical products. In Australia, we have a list of 'prescribed' or 'declared' products, and these require mandatory type testing, and must have an 'RCM' (regulatory compliance mark) (formerly an 'A-Tick' or 'C-Tick') that indicates that tests have been performed. The model number is listed with the ACMA (Australian Communications and Media Authority), and it's a requirement that declared products are registered with ACMA. This requires the supplier to have a valid equipment test report, a 'Statement of Compliance Form' or Declaration of Conformity (DoC), and maintain a compliance folder. Finally label the product with the RCM logo, after applying to the ACMA to allow the use of the logo. The scheme is also overseen by the Electrical Equipment Safety System (EESS). See Regulatory Compliance Mark. I quote from the web page ...

For electrical safety, in-scope electrical equipment must not be sold unless the item is marked with the RCM in compliance with AS/NZS 4417.1 & 2 and the EESS.

'In scope' simply means any prescribed or declared product. Amongst these are external power supplies and battery chargers. An 'external power supply' means any power supply that connects to mains voltage (either with a mains lead [detachable or attached] or that plugs directly into a wall outlet).

RFI/ EMI may often be the least of one's concerns though, as many of the cheap supplies you can get are dangerous. There was a case in Sydney a few years ago when a young woman was killed by a fake 'name brand' phone charger, and I've seen quite a few that wouldn't pass even the most cursory examination, let alone a full lab test. One practice that's common in cheap 'knock-off' SMPS (switchmode power supplies) is the use of an 'ordinary' 1kV ceramic capacitor, where regulations worldwide call for a Class-Y component, with full certification and marked with multiple standards. Needless to say, Class-Y caps are more expensive, but they are specifically designed to ensure that a short-circuit failure is as close to impossible as you can get.

Many countries require that certain classes of electrical equipment must have been laboratory tested to ensure compliance with applicable directives or other laws or statutes. Unfortunately, there's very little co-operation between 'trading zones', so a single product may have to undergo several bouts of testing to meet the requirements of all countries where it's to be sold. This is a significant financial burden, and it's usually impractical for small-scale manufacturers. This is often 'circumvented' by allowing individuals from anywhere to purchase the equipment from its country of origin, and the purchaser then becomes the importer. If it's for personal use there's no real problem if it's safe and doesn't interfere with other equipment, but if it's sold to someone else (and this often includes hire, lease and even gifts) then the rules apply. Should a 'personally imported' product cause injury or death, the importer (which may be you) risks becoming liable.

Regulatory Compliance Mark (RCM) - Australia/ New Zealand

While you will almost always get a compliant (and therefore as safe as can be expected) from reputable suppliers, the same cannot be said for products obtained from 'flea markets', eBay, Amazon, etc. Same may be perfectly alright, but others are either seriously dangerous, or can be expected to cause radio frequency interference (RFI) aka electromagnetic interference (EMI) that may interfere with the operation of other equipment (including WI-Fi, Bluetooth, AM/ FM radio or TV reception). Just because a cheap phone charger doesn't try to kill you the first time it's used does not mean that it's safe. Some faults (including potentially lethal ones) may not manifest themselves for some time. The problem is that no-one knows when (or how) the device will become dangerous.

You'll often see power supplies (and other goods) that appear to have the CE (from the French 'Conformité Européenne') mark, which certifies that a product has met EU health, safety, and environmental requirements. However, the presence of the CE logo does not indicate that the product has been tested to ensure consumer safety. Manufacturers in the European Union (EU) and abroad must meet CE marking requirements where applicable in order to sell their products in Europe. To add to the confusion, there's a remarkably similar 'CE' logo which supposedly indicates 'China Export'. It's doubtful that this is a coincidence - it's just a trick to fool consumers. However, note that the CE logo is not necessarily an indicator for electrical (or other) safety, and other EU (European Union) rules may also apply - in particular the 'Low Voltage' and EMC (electromagnetic compatibility) Directives.

Real 'CE' (Left) and Fake 'China Export' (Right) CE Logos

The 'real' CE logo is made from letters formed within overlapping circles, and the spacing is as shown (the 'construction' lines in grey are not part of the logo). The 'China Export' logo is almost identical, but the letters are more closely spaced. Very few people would realise the implications, and would assume that the product meets European standards. If the logo is 'China Export', it is completely meaningless, but most people wouldn't notice the difference. It's safe to assume that was the intention from the outset.

NOTE: For a good explanation of all compliance marks, see Power Supply Safety Standards, Agencies, And Marks (CUI Inc.)

In Australia/ New Zealand, the US, Europe and almost certainly other countries, there's a requirement that external power supplies (plug-pack or 'brick' types, including battery chargers) must comply with the standards for no-load power consumption. In Australia/ New Zealand the scheme is called MEPS (minimum energy performance standards) although the acronym will be different elsewhere. There's an assumption (which IMO is badly flawed) that these power supplies will be powered on permanently (see The Humble Wall Transformer is the Latest Target for Legislators. Regardless of the reality, external PSUs must meet the performance standards that apply in any country with a similar scheme. A good example is shown at Efficiency Standards for External Power Supplies (CUI). As always, the full data is only available if you purchase the relevant standards documents, at considerable expense!

Goods intended for sale in the EU must also comply with RoHS (restriction of hazardous substances), meaning that only lead-free solder can be used. They must also comply with the LVD (low voltage directive) and EMC (electromagnetic compliance) directive. These rules may also be applied elsewhere, but it's generally fairly haphazard outside of the EU. Like many people, I really dislike lead-free solder, but if that's required then the item should be marked as such. I found a rather amusing ad on an on-line site for a plug-pack supply, and the dopey seller included a photo of the PCB, showing that it had zero parts for EMI suppression. This ensures that it would fail any proper test procedure, because it will generate high levels of RF interference. At least anyone who knows about switchmode supplies would recognise its failings without having to buy one.

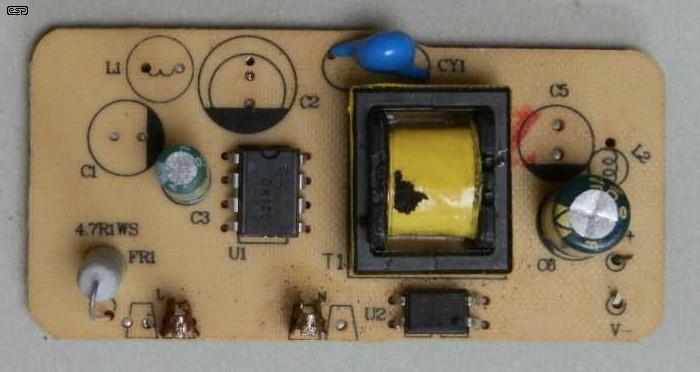

Figure 1.4 - PCB Image Shown On Seller's Listing

I freely admit that the image is basically 'stolen', something I would normally never do. However, this illustrates the issues discussed here and I considered it 'fair game'. Overall, the PCB looks rather like that shown in Fig. 4.3, and while it has provision for an output filter inductor, it's not fitted. The remnants of dashed red lines are where the seller pointed out 'special' features, such as "Large Capacitor" and "Third Generation Smart IC Chip", to which I would reply "Bollocks!". The fuse is referenced as (and I kid you not) "Circuit Safe Running Safety Tube". The transformer is claimed to be 'high quality', but I fear that's impossible to verify from a photo. Interestingly, the same seller shows the PCB for a 12V, 2A version which has proper EMI filtering and is a much better proposition, although there's no indication that it meets any applicable standards for Australia or anywhere else.

I don't propose to even try to cover the rules that apply in each country or trading zone, as there are far too many. Australia/ New Zealand use AS/NZS standards, the US/ Canada have UL and FCC requirements, Germany has VDE, Great Britain has British Standards (BS), etc. For a reasonable overview, see Electrical Safety Standards (Wikipedia). In almost every case, the requirements of any of the standards documents are not freely available, and the relevant documents have to be purchased at considerable cost. I consider this to be an abomination - all of us should have access to information that would help us to decide whether or not to return a device should it be found non-compliant, and DIY people should be able to access information needed to ensure that their project is compliant with applicable regulations.

With the almost universal adoption of switchmode power supplies for plug-packs/ wall transformers, the requirements for electrical safety are more important than ever before. Older types used a conventional mains frequency transformer, and these were pretty close to being intrinsically safe. Nothing can ever be 100% safe under all circumstances of course, but the difference between a mains transformer and a SMPS is chalk and cheese. When (almost always Chinese) manufacturers decide to cut corners to the extent they often do for cheap 'after-market' products, important safety (and other) requirements are bypassed, leaving the customer with a product that is dangerous.

Two of the mandatory requirements worldwide are electrical safety and radio frequency interference (RFI) and/ or electromagnetic compatibility (EMC). Products must have suitable circuitry to minimise risk and interference, but it's common to see these omitted in low-cost (and usually unmarked) products. In most countries, it's an offence to sell non-compliant products. I've seen several plug-pack supplies that have no interference blocking, generally a common-mode inductor plus one or more X-Class (mains rated, usually X3) capacitors. A further requirement is almost always a capacitor from the mains (hot) side of the PSU to the DC output, and if this isn't included few SMPS would ever pass 'radiated emissions' tests (a measure of how much RF interference is radiated into nearby equipment). This must be a Y1-Class capacitor. The IEC 60384-14 safety capacitor subclasses are ...

| Class-X | Class-Y |

| Y4 - < 150VAC | |

| X3 - peak voltage pulse of ≤ 1.2kV | Y3 - ≤ 150VAC up to 250VAC |

| X2 - peak voltage pulse of ≤ 2.5kV | Y2 - ≤ 150VAC up to 300VAC |

| X1 - between 2.5kV and ≤ 4.0kV | Y1 - ≤ 500VAC |

The only capacitor that may be connected between mains voltage and an isolated ('safe') output is a Class-Y1, and a standard 1kV ceramic cap does not comply. Most standard ceramic caps have a 5mm (0.2" or 5.08mm to be exact) pin spacing, where a Y1 cap will use 10mm spacing. This provides sufficient creepage distance across the PCB surface to withstand mains voltage, where a 5mm spaced cap only allows about 3mm once the PCB pads are included. The minimum is generally 5mm, but in most cases reputable manufacturers will allow at least 7mm creepage.

These are two terms that most people do not understand. This is not surprising, because although they are self-explanatory, the explanations themselves don't mean anything without context. Clearance is the distance, through air, separating hazardous voltage from phase to neutral, earth or any other voltage. The minimum value is typically 5mm, but there is a vast variation depending on pollution categories (not normally applicable inside sealed equipment) and voltage. Using the minimum figure is not sensible for hobbyists, and it's preferable to ensure that the separation is as great as possible.

Creepage is the distance across the surface of insulating material, including printed circuit boards, plastic terminal blocks, or any other material used to separate hazardous voltages from phase to neutral, earth, or any other voltage. Again, 5mm is generally considered 'safe', but that depends on the material itself, pollution categories (again) and the voltage(s) involved. Note that the creepage distance is from the closest edges of PCB copper pads or tracks, and not the pins of the connector or other device. The following drawing shows the difference between creepage and clearance.

Creepage And Clearance Distance Measurement

In the above, creepage is shown between two transformer windings (only the layer adjacent to the primary/ secondary insulation is shown). The second drawing shows creepage across the PCB and clearance between the wire 'cups' on a barrier type terminal block. Creepage exists on both sides of the board. Where pollution is expected, this may be able to bridge the creepage distance with partially conductive 'stuff', possibly allowing sufficient current to cause fire or injury (including death) to the user. Be aware that burnt materials (such as PCB resins) can become carbonised (and therefore conductive) if heated beyond their rated maximum temperature. The lower drawing shows a Class-Y1 capacitor, one wired conventionally, and the other with a slot in the PCB to increase the creepage distance, so clearance becomes dominant.

The above is adapted from Electrical Safety - Requirements And Standards on the ESP website. While that article covers similar material to that shown here, this one is specific to plug-pack power supplies. It was prompted when I stripped down a small PSU I obtained (knowing in advance that it was almost certainly non-compliant). It cost me less than AU$2.00 including post, so the seller made a loss on the transaction.

A potentially useful test you can perform (if you have the equipment) is a 'Megger' test. The Megger™ and similar insulation testers operate at either 500V or 1kV, and test insulation resistance. Mine isn't the original, but it tests at 1kV up to 2,000MΩ. If anything breaks down during the test (which is pretty severe) then the item cannot be used. 'Proper' lab tests usually include (literally) testing to destruction, with the required tests described in the applicable standards documents (which of course you cannot obtain without paying through the nose for them).

Unfortunately for everyone, the vast majority of these supplies are designed to be non-serviceable, and you can't see what's inside without breaking the case apart. Otherwise, a visual check could be done easily enough, so you can look at the creepage distances provided, check that the Class-Y1 cap is the 'real thing', and verify that the EMI filters are included. To save everyone at least some pain, I've included photos below that show both compliant and non-compliant PSUs. Some may appear alright, but still not have the appropriate safety certifications, and if that's the case you use it at your own risk.

Be aware that the presence of compliance marks is no guarantee that the product has actually been tested. It's not at all uncommon for these markings/ logos to be faked, because it's just a logo that can be printed on the sticker, incorporated into the injection moulding die or laser etched into the plastic body. It has to be understood that counterfeit transistors, ICs and even electrolytic capacitors are a serious scourge on the electronics supply chain (and it even happens with aircraft and aerospace products - NASA has been caught out).

The techniques used by suppliers are sometimes very crude and easily detected, but others are so good that they are very difficult to detect without specialised equipment. With this in mind, what hope is there for the 'ordinary' consumer? With small 'disposable' electronics like plug-pack power supplies, there can be anything inside, and you'll never know unless it's dismantled. This is why I suggest buying only from reputable sellers. You will pay more, but at least you have some certainty that it won't try to kill you.

Sometimes you find 'stuff' that almost defies belief. I have a couple of SMPS units that were once part of something else. The PCB (non-compliant) was liberated from its original housing, re-wired and re-packaged into a 'new' wall transformer housing. I have two (never intended to be used as plug-packs), one of which completely wipes out the FM radio in my workshop. The sale of these in Australia is prohibited because they have no compliance markings (one had a UK plug!), but some eBay sellers are oblivious to the rules, or perhaps they just don't care if someone dies because of their dodgy products.

Figure 3.1 - Basic SMPS Schematic #1

The drawing is adapted from the CSC7203 datasheet. As near as I can tell, the IC manufacturer is in China, and as shown it has a reasonable chance of passing both electrical safety and EMI/ EMC tests for most countries. However, I have a (Chinese, no certifications) SMPS using this IC, and every part needed to make it compliant is missing. There's no input fuse (just a 4.7Ω 'flameproof' resistor), no X-Class caps or TVS (transient voltage suppressor) and no common-mode inductor. The cap marked 'CY1' was a 1kV ceramic (not Class-Y1) and is dangerous. The minimum creepage distance is less than 5mm, and is only 3mm where the 1kV ceramic was placed. The isolation of the transformer is unknown, but it did pass a 1kV test from my insulation tester.

However, I would use this PSU only in a Class-I device (using a safety earth as the secondary barrier against electric shock). It would never be used in anything other than a piece of test gear, that I alone would use. All supplies of this type are supposed to be constructed (and tested) to Class-II (double-insulated) standards. Of real concern is the fact that the transformer's winding window is only half-filled, which indicates that the wire is thinner than it should be, and there's likely to be insufficient insulation between primary and secondary. None of this inspires confidence.

The output regulation is via a zener diode (not a voltage reference as shown in the drawing), and secondary filtering consists of a single electrolytic capacitor. There's no inductor to ensure low levels of EMI on the DC output. The same applies to countless other (very similar) ICs, which are available from multiple manufacturers. They nearly always show the EMI and safety components in the 'typical application circuit', but the SMPS will function without them.

Just because a circuit works, that doesn't mean that it complies with mandatory EMC of safety regulations. This is particularly true if the minimum creepage (and/ or clearance) conditions aren't met. Any PCB contamination (from a failed [usually explosively] electrolytic capacitor for example). Many cheap SMPS use phenolic PCBs (the same stuff that Veroboard is made from). This is nowhere near as robust as fibreglass (FR4), and it is more sensitive to humidity. It's used because it's much cheaper than fibreglass, and it's usually reinforced with paper, so it's easier on tools (drills, routers, guillotines, etc.). I consider it to be marginal for mains usage, but it's usually alright if safety-critical parts of the PCB are routed through, or wider than 'normal' creepage distances are used.

In some cases, the minimum creepage distance is set by an optocoupler. These usually have the standard 0.3" (7.62mm) spacing, allowing a couple of millimetres for the pads. SMD types may have a narrower pin spacing, and a cut-out beneath the optocoupler is good practice.

Figure 3.2 - Basic SMPS Schematic #2 (Simplified)

In the second drawing, a different approach is used. Rather than regulating the secondary via an optocoupler, the primary side is regulated using the supply for the IC. This means there's only one thing that has to provide full isolation, and that's the transformer. The above is adapted from an application circuit for the TNY267, an IC made by Power Integrations. In the datasheet, they state that "The TinySwitch-II oscillator incorporates circuitry that introduces a small amount of frequency jitter, typically 8 kHz peak-to-peak, to minimize EMI emission. The modulation rate of the frequency jitter is set to 1kHz to optimize EMI reduction for both average and quasi-peak emissions."

Stated another way, the circuit is designed specifically to ensure it will pass EMI tests using the standard test procedures. Fortunately, that also means that it won't cause significant EMI, as the test process is wide-band and will pick up any 'errant' frequencies that may be generated. The above quote is intended for designers, so they know before formal testing that the SMPS is unlikely to fail (that means re-testing, at considerable extra expense). It's interesting that the application circuit does not include a Class-Y1 capacitor, which is unusual.

The point here is that I can find (as can you) any number of off-line (mains powered) SMPS circuits, and many of them are flawed beyond belief. I will not show these circuits, nor provide links, because they are a menace and should never have been published. Just about any PSU design can be simplified dramatically, but at the cost of high levels of interference, and deplorably low standards for safety. One I saw used a half-wave rectifier so the output could be referred to the mains Neutral. In theory this is 'safe', but regulations worldwide state that the Neutral is to be considered as 'live', because many power outlets are not polarised.

I have taken photos of a selection of compliant and non-compliant SMPS. If you're willing to dismantle the supply it's fairly easy to see if it's likely to be compliant or not, but otherwise you rely on external markings (CE, UL, RCM, etc.) which may or may not be real. There's no way to know by looking at the logos or other markings, but if any PSU is much cheaper than from a reputable supplier then assume the worst.

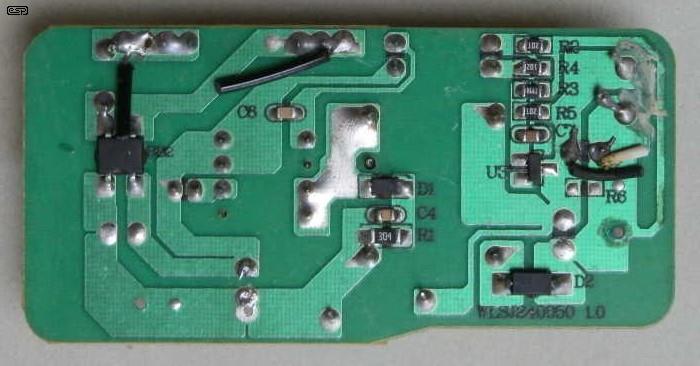

Figure 4.1 - Complete Rubbish #1 (Top View)

This supply has had its input filter cap removed, but is otherwise intact. It was installed in a housing that didn't use the two AC 'connectors' (bottom left), and had wires running to the AC pins. This was quite obviously 'recycled', which isn't an issue per se, but it would not comply with any EMI tests as there are zero RF filtering parts installed. There's space for an input inductor (L1, top left) and an output inductor (L2, right centre). At least the Y1 cap really is a Y1 cap, or so it's marked. It could also be a fake.

Figure 4.2 - Complete Rubbish #1 (Bottom View)

The bottom view shows that the isolation barrier is acceptable, but we don't know if the transformer would withstand any serious test voltage. A recycled supply is not what you expect when you buy it 'new', but I was fully aware that it wasn't the 'real deal' when I paid AU$1.80 for it (including postage!).

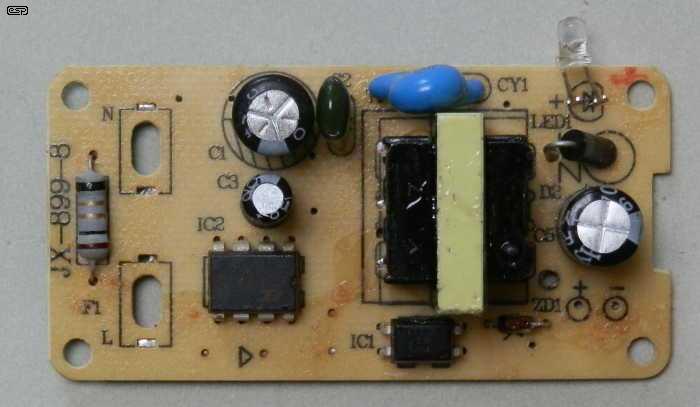

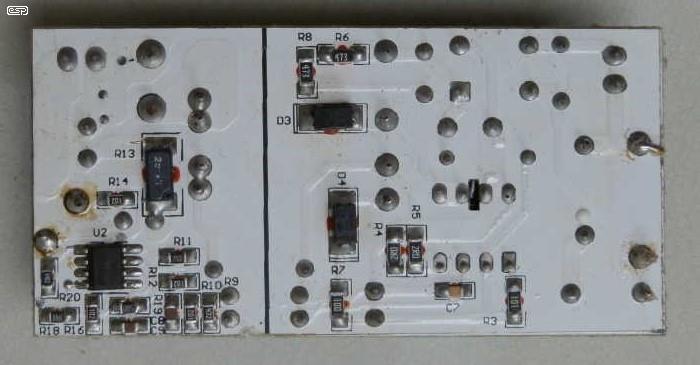

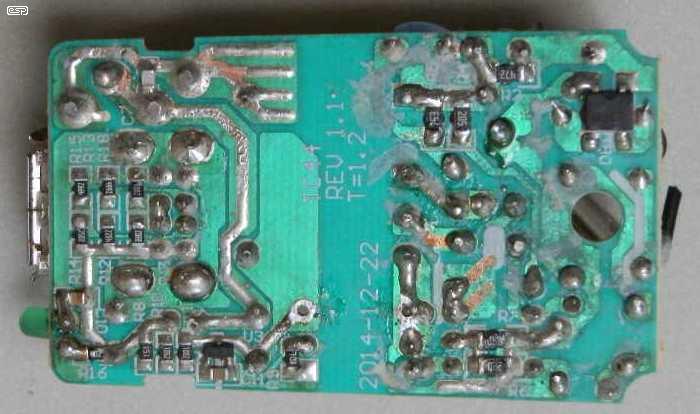

Figure 4.3 - Complete Rubbish #2 (Top View)

Here's another one, but this one originally had a 1kV ceramic capacitor instead of a Y1 cap (even though the PCB is marked 'CY1', top right). The separation between 'hot' and 'safe' sides of the PCB is inadequate, with the minimum being only 3mm. I replaced the 1kV cap with a Y1 cap, but this supply could not be trusted as a Class-II (double-insulated) device, because it doesn't comply.

Figure 4.4 - Complete Rubbish #2 (Bottom View)

The so-called 'isolation barrier' is the empty section. You can see where the original 1kV cap was (top mid-left), and I drilled a new hole to accommodate the wider pin spacing for a Y1 cap. This supply doesn't even have provision for input or output EMI filtering, so it was obviously designed by an idiot. The transformer winding window is half empty (not visible in the pix), which tells me that there is almost certainly nowhere near enough insulation.

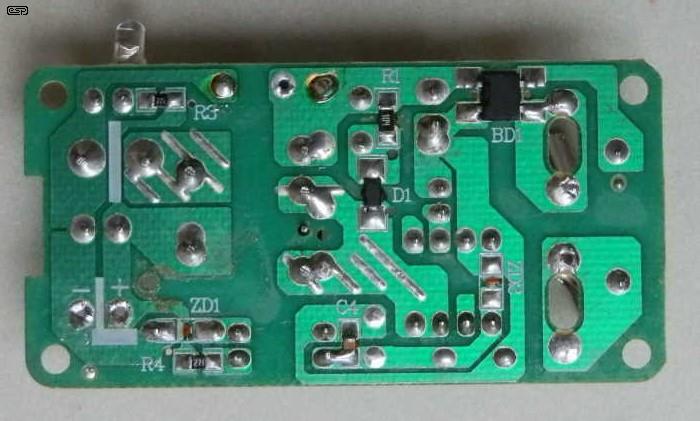

Figure 4.5 - LED Driver Supply (Top View)

By way of comparison, Fig. 4.5 shows a LED driver board which has everything required. The X3 cap is installed as part of the EMI filter, it has a fuse, inductor and MOV for input protection and is built to a high standard. At the output, there are two filter caps and an inductor, so I'd expect this supply to be compliant.

Figure 4.6 - LED Driver Supply (Bottom View)

The bottom view shows a clearly defined isolation barrier (the dark vertical line), and it has compliant distance between the 'hot' and 'safe' sides of the supply. This is what we should expect to see in a SMPS, but if you buy on an extreme budget expect to see 'complete rubbish'.

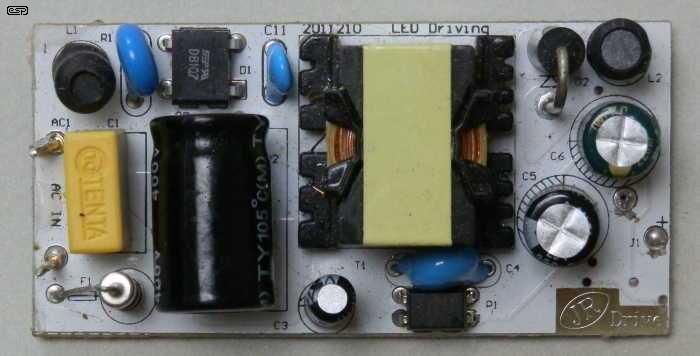

Figure 4.7 - USB Charger Supply (Top View)

This USB charger failed, with a rather loud BANG right next to me at the time. However, nothing became dangerous, and you can see that the input electro (400V) has exploded. The shrapnel was contained, but as the next image shows there was considerable PCB contamination when the electro started to leak. Consider that this supply was no more than a couple of years old when it blew up. It has all the required markings allowing it to be sold in Australia. Note that the Y1 cap was removed to install into the Fig. 4.3 supply.

Figure 4.8 - USB Charger Supply (Bottom View)

PCB contamination is obvious on the right side of the PCB. However, it hasn't bridged the isolation barrier, so it never became dangerous. This is why the creepage and clearance distances are so important. A 3mm barrier could easily have been bridged by the electro's contents, but it's also important to note that the failed electro is as far from the isolation barrier as possible.

There is a limit to the number of photos I can provide, but I hope you now have the general idea. 'Budget' almost certainly means the supply is non-compliant with mandatory safety requirements, and as noted earlier if you purchase one of these from overseas you become the importer, and will probably be held liable if anyone is injured or killed. The risk is obvious, but only if you pull the supply apart. This means that it's no longer safe to use, even if it is (or appears to be) compliant with applicable standards.

If you need a plug-pack style power supply, it should be obvious that buying from random on-line sellers (on any platform) is unwise. Reputable suppliers will only sell compliant products, because the risk of selling anything else is not worth it. There are very heavy fines imposed in Australia, and no doubt much the same applies elsewhere - the EU is well known for strict safety requirements (as it should be).

Most people will be unaware that mains leads (power cords) have a mandatory approvals requirement to allow them to be sold in Australia. Many other countries will have similar rules, and it is illigal to sell (including trade, swap or loan) unapproved cables. As a result, it's almost certain that not one of the 'high-end' power cables sold is legal. Any hi-fi shop selling them is liable for prosecution if found to be selling un-approved mains cables.

For the worst possible example of a non-compliant mains lead, see Electrical Safety - Requirements And Standards, Section 10. This is best described as a travesty, and it would not pass safety testing in any country on Earth. This was supplied by an eBay seller, along with a (non-compliant in Australia) 12V, 10A power supply (which was recycled). The supply may not have approvals, but I've determined that it is 'safe' - at least for the application where it will be used (which will be in an earthed metal case).

There are very good reasons for the requirements, with electrical safety being the most obvious. The cables (including distribution boards and extension leads) must have the RCM (or approval number for earlier products) moulded into the plug/ socket and/ or the lead itself. There are no exemptions, but people are permitted to make their own extension leads or mains leads, provided they are not offered for sale. All manufactured cables are covered by AS/NZS 3112 (Australian/ New Zealand Standards).

Similar requirements apply elsewhere, and most products need to comply with IEC requirements (IEC standard means an International Electrotechnical Commission standard). There's a lot of info at the EESS (Electrical Equipment Safety System) website. In one section, they state ...

A Responsible Supplier (on-shore manufacturer or importer) must meet all the requirements of the EESS, including:

Second or subsequent suppliers in the supply chain must ensure that electrical equipment offered for sale complies with the following:

The info above is directly from the EESS website.

The above apply equally to small power supplies, so local (Australian) eBay sellers are breaking the law if they sell unapproved power supplies, 'high-end' mains cables or any other products that don't comply with mandatory standards. Even a cursory look through any of the online 'market places' will reveal countless non-compliant products.

I expect that the ramifications of cheap (but definitely not cheerful) SMPS are fairly clear. If you buy on-line (eBay, Amazon, etc.) you usually have no idea if a power supply is approved for use where you live or not, until it arrives and you're willing to take it apart if it looks dodgy. Not everyone knows what to look for, and I hope this article helps readers to know what's important. In almost all countries (or trading zones like the EU) there are specific markings indicating approval, but they aren't necessarily genuine. The old adage "if it looks too good to be true then it probably is" applies in all cases for sellers who aren't 'reputable'. Retail outlets and well known suppliers will almost always ensure that they don't fall foul of the regulatory bodies, as the penalties can be severe, and doubly so if someone is injured by the product they sell.

On-line sellers think they can get away with it, and if they're in another country they are probably right. That's because you become the importer, and therefore you are responsible for the suitability of the product for use where you live. If you have no idea what to look for, this places you at considerable risk, and doubly so if you re-sell the product to others. While you can certainly purchase a budget supply, dismantle it, and test it thoroughly, very few people have the necessary equipment to run the electrical safety tests, and testing for EMI is even harder. Even if you do determine that the PSU is safe and free from any interference problems, you then have to put it back together so that the case is properly and securely joined. In most cases, getting it apart will cause damage that can't be repaired easily, and it becomes a potential death trap.

Unfortunately, on-line 'marketplaces' have little or no idea of what their sellers are permitted to sell, so unsafe power supplies are a major problem. It seems that there's no incentive (or no real disincentive) to prevent the sale of non-compliant and possibly dangerous products. I have attempted to alert NSW Fair Trading on a number of occasions (Fair Trading is one of the Australian bodies who look for prohibited or unsafe goods, amongst other things). To say that my attempts were generally unsatisfactory would be an understatement. The same will apply elsewhere, so the only option is to buy plug-pack power supplies from known and reputable sellers. These should ideally have a 'bricks and mortar' outlet (i.e. a physical shop) where you can examine products before buying to ensure they have the proper approvals.

For the most comprehensive documentation I've seen, I recommend Mean Well User Technical Manual, which I found after this article was published. It applies mainly to larger ('frame' type) supplies, but it has much useful information that isn't available elsewhere.

Main Index Main Index  Articles Index Articles Index |