|

| Elliott Sound Products | Project 141 |

PCBs are available for this project. Click on the PCB image for details.

PCBs are available for this project. Click on the PCB image for details.A constant problem for home theatre buffs is how to control 6 or 8 channels at once. Multi-ganged pots are really hard to get, and most you find are so-called log types. These have poor tracking - as much as 3dB tracking error at low settings, and some may be worse. Linear pots with a padding ('law-faking') resistor as shown in Project 01 are better, but linear multi-ganged pots are even harder to find.

So, what to do? Digital pots certainly have some advantages, but with most you need to provide a backup battery so they will remember where they were set when you switch off your system. The majority also have to be driven by a microcontroller of some kind, and they nearly all are limited to a single 5V supply which severely limits available headroom. There's nothing quite as simple as a pot to adjust the volume, but that has to be interfaced to the microcontroller.

Up and Down buttons are usually acceptable on a remote, but are a nuisance on the preamp itself. Apart from the general nuisance value of buttons, you also need a digital display to show the volume level otherwise you have no idea how loud the system will be when it starts playing. Adding the display introduces digital switching noise that requires great care with shielding so you don't get a background noise from the digital circuitry.

Naturally, all of the above problems can be solved, but the end result is usually a dedicated system that can't easily be expanded (or contracted) if needed. For example, a PCB that's set up for 8 channels (for a 7.1 system) can be a significant size, and will be almost certainly be double-sided and may require SMD parts because through-hole digital pots are getting difficult to find. Such a large board is hardly economical if you only need two channels.

Likewise, a 2-channel system may be difficult or even impossible to expand if you need 6 or 8 channels. Naturally, there is a negative side to the approach suggested here. The THAT2180 (or THAT2181) is not an inexpensive part - expect to pay at least $12 each for the lowest specification version (THAT2180C - 0.05% THD). Depending on where you get them, the cost may be considerably higher. If you see them for significantly less, you may be getting fakes (I don't know if fakes exist, but always assume the worst). CoolAudio makes an equivalent device (the V2181) which appears to be much the same as the THAT2181B. Availability is somewhat variable, and I've not tested these.

I would not have even thought this project possible, had I not obtained some THAT2180B voltage controlled amplifier (VCA) chips for testing and experimentation purposes. I bought 2 pairs - one pair from ebay (a risk I know) and the other pair from a major distributor. Needless to say there was a significant price difference. I've compared all 4 VCAs in a simple dual-channel prototype board, and found that the gain variation between the devices is astonishingly small - much better than a dual gang linear pot that I also tested!

I tested over a wide range of control voltage - the THAT2180 is rated for a gain variation of 6mV/dB, so a 6mV change in the control voltage causes a 1dB change of output. This means that the gain change is logarithmic with a linear control voltage, and the log law is far more accurate than almost any log pot. The device works as an amplifier and attenuator, so a complete preamp channel can theoretically use just the VCA chip plus an opamp as a current-voltage converter. In reality, this is a bad idea though, because the output impedance of most sources is not defined, so an input buffer is needed as well.

The maximum control voltage is ±540mV, giving a theoretical gain range of 180dB (1.08V / 6mV). Needless to say, this is actually impossible, but the makers claim >130dB gain range and 120dB dynamic range. The suggested gain range is from -60 to +40dB, but for most preamps the positive gain will typically be between 10-20dB at most. The ICs themselves are a single in-line pin (SIP 8) package, and two can go side-by-side in a single 16 pin IC socket. The ICs are laser trimmed, and distortion is quoted at 0.02% for the 2180B (middle of the range and best value for money). To obtain a maximum gain of 30dB requires the control voltage to be limited to -180mV, and maximum attenuation is 90dB with a CV of 540mV (if the Ec+ control pin is used, these are reversed).

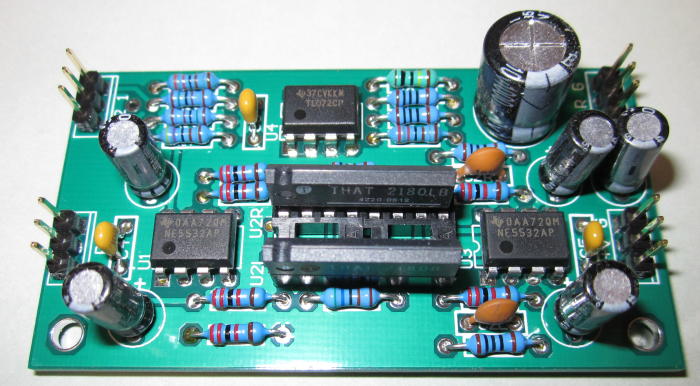

Photo Of Completed PCB

The basic datasheet reference circuit (with modifications) is shown below. The VCA has two available control voltage inputs, one inverting and the other non-inverting. It doesn't matter which is used - both can be used if desired, but there's little advantage doing so. The recommended source impedance for the CV inputs is zero ohms, but in any case should be less than 50 ohms. During my tests I found that a bypassed 100 ohm resistor is fine, but the bypass cap really does need to be large or distortion is increased very noticeably. Very low impedances are irksome, because even direct drive from an opamp will show an impedance that rises with frequency, although that can be corrected with a Zobel network. With a direct-coupled approach, opamp noise also becomes a problem. The datasheet suggests that pin 3 (the Ec- input) be used, with pin 2 connected to earth. With this arrangement, a positive input reduces the gain.

Both audio signal input and output are currents, with a resistor providing voltage to current conversion at the input, and an opamp (U2) converting current to voltage at the output. A feedback cap (C2) will be needed to prevent ringing with fast transients. The VCA has a small amount of capacitance at the output port that requires compensation. With some opamps C2 may need to be larger than the 15pF shown. Even as much as 47pF will not affect the audio band.

Figure 1 - Modified Datasheet Test Circuit For THAT2180

Although the datasheet suggests using an OP275 opamp, this is only one of many options. For my tests I used a TL072, but you can also use an OPA2134 or NE5532, but the latter will probably have a few millivolts of DC offset so requires an output coupling cap. Although many people seem to have an unnatural aversion to capacitors in the signal path, there is no good reason not to use them, and many excellent reasons to always AC couple inputs and outputs. Capacitors are much maligned, but are actually most excellent components that refuse to damage the sound unless you choose something entirely inappropriate.

One thing that is extremely important is to ensure that the control voltage is noise-free. Since the gain is varied at the rate of 6mV/dB, if there were 6mV of noise on the control pin, that means the audio would be modulated by ±0.5dB. It's obviously essential to minimise the noise that can appear on the control voltage. Fortunately, we don't have any digital signals to worry about because the entire circuit is analogue, so keeping noise low isn't as hard as it might be otherwise. The other trick we can use is to make the control voltage 10 times that needed, and attenuate (and filter) it right at the VCA chips. It is necessary to go to a bit of extra trouble though, because the impedance at the control ports should be as low as possible. We will go one better - the control voltage will be attenuated by a 23:1 ratio.

The datasheet for the THAT2180 states that the impedance at pin 3 (negative control voltage) should be less than 50Ω. The circuit shown beats that easily, and at 20Hz the impedance is about 8Ω, falling with increasing frequency. At 100Hz it's only 1.6Ω and it continues to fall until the capacitor's ESR (equivalent series resistance) becomes dominant. A 1,000µF, 10V electro can be expected to have an ESR of about 100mΩ (0.1Ω).

Not shown in the datasheet circuit is the attenuation network (2.2k and 100 ohm resistors) that forms a 23:1 voltage divider, bypassed by the 1,000µF cap. You can use two caps in series (back-to-back) because the voltage could be positive or negative, but a single cap is fine because the reverse voltage is well below 100mV at any sensible positive gain setting. Electros will tolerate reverse polarity below 1V without problems (this has been tested and verified). With the values shown, a control voltage swing of ±12V will give an attenuated swing of ±520mV. The negative polarity has to be reduced though, because just -180mV (-4.14V at the CV input) will give 30dB gain, and that is way too much for a typical preamp.

We'd normally aim for a maximum gain of perhaps 10dB, and that only needs a CV of -60mV (-1.38V at the CV input using the attenuator as shown). Naturally, this can be preset with a voltage divider as shown in the control voltage schematic. Making it adjustable is not a problem (change R17 to a 5k trimpot), and that is a sensible approach. It's even possible (although unnecessary) to make the CV for each individual VCA adjustable so they can be perfectly aligned. However, since the typical maximum gain error at 0dB gain is only 0.15dB this is already far better than the vast majority of potentiometers. Only a switched attenuator will be better ... but remote control of those is irksome to put it mildly.

The 1,000µF bypass cap on the control voltage input is essential. During initial tests I used a much smaller value, and found that distortion figures were considerably higher than expected. In particular, there was a fairly strong second harmonic component - much more than claimed in the datasheet. Increasing the capacitance to 1,000µF made the distortion all but disappear. The recommended capacitor has an impedance of only 8 ohms at 20Hz and it's much less at higher frequencies. Although it does cause a small delay between application of the control voltage and anything happening, it's so short that it will not be noticed in use.

Figure 2 - Control Voltage Circuit

The control voltage can be derived using a pot connected to the supply rails (via an attenuator network for the negative supply). The final CV has to be buffered though, because the impedance for each VCA (or pair of VCAs as seen in the final circuit) has to be 2.2k as shown in Figure 1. It's not possible to load a pot that heavily without seriously affecting the law of the pot (it has to be linear). Even using an opamp is a problem, because most get annoyed if we try to draw too much current from the output. To minimise opamp loading, we could add a couple of transistors act as buffers, but its far easier to just parallel two opamps. This circuit can drive a load of less than 1k easily, and although it's overkill there is virtually no cost penalty. Noise is not a problem because it is heavily attenuated by the resistors and the 1,000µF capacitor at the VCA control voltage input. In the PCB version, each board uses its own paralleled buffer so pot and/or opamp loading isn't an issue at all.

With the arrangement shown, the CV can be varied between -85mV (14.2dB gain) to 555mV (-92dB), but the gain can be modified by changing R17. Increase the value to get lower maximum gain. The minimum gain (maximum attenuation) will also be affected by R17, but not enough to worry about. -90dB is not really necessary, and you'll almost certainly find that less attenuation is more than acceptable. Note that VR1 must be a linear pot. If you use a motorised pot, you'll have to dismantle it and replace the log taper wafers with linear - it's actually quite easy to do. Because the pot is only used to obtain a control voltage, there's no point getting an expensive one, it only needs to be adaptable so you can replace the wafers.

The full channel circuit is shown below. Only the left channel is shown, and the right channel is the same, and uses the same control voltage (separate CV attenuators are not used or needed). U1 is a unity-gain buffer, which ensures that the impedance at the input of the 2180 is defined regardless of the source impedance. As you can see, the complete circuit is very similar to the test circuit shown in Figure 1. Despite appearances, the complete circuit is non-inverting. The VCA provides a negative output current for a positive input current, and this is inverted by the final opamp (U3A - current/ voltage converter).

Figure 3 - Complete Channel Circuit

Typically, you'd have a pair of VCAs and their associated circuitry on a single board, along with the control voltage buffer. A single pot can link to any number of CV buffers (within reason of course), so a six or eight channel system is simple to assemble. However, it won't be cheap - the VCAs are reasonably expensive devices, but unlike 8-gang pots you can get 2180 ICs. It's not necessary to use the 2180A or B versions for surround channels or subwoofers - the C version is more than satisfactory, and the higher distortion (all of 0.05% THD) is of little consequence for the application. Indeed, I'd expect that many constructors would be more than happy with the 2180C for everything, but make sure you read the datasheet first. Not only is distortion higher, but the gain tolerance is not as good as the others.

The final attenuator is designed to ensure that the VCAs get the cleanest control voltages possible. The output from the opamp buffers is attenuated by 27dB for DC, but with AC that increases to nearly 57dB at 50Hz, or 58dB at 60Hz. Even long control leads won't inject any noise, provided they are shielded. If you do use long leads to the pot, adding a 220µF (or more if you prefer) capacitor from the pot's Pin 3 connector (+ve to ground) means that Pin 3 can be used for the shield, so you can use 2-core shielded cable. To ensure good grounding for RF, it would be a good idea to include a 100nF ceramic cap in parallel with the electrolytic cap. The voltage at that point is under 2V DC, so a low voltage electro can be used.

This project is designed for both stereo and multi-channel home theatre systems. The normal Left and Right channels will be more than satisfactory for music reproduction, so a preamp based on Project 141 is truly multi-purpose. The number of channels can be selected to suit the way your system is set up. For example, if you tell the DVD or Blu-ray player's decoder (assuming analogue outputs of course) that you have large full-range main speakers, no subwoofer or centre channel, but you do have rear surround speakers, you only need 4 channels. The decoder will then send the main Left and Right signals (including LFE - low frequency effects) to the main speakers, and your crossover (such as Project 09) will separate the low frequencies, rather than having the decoder do it - most have minimal adjustment and the LFE channel extends too high for proper stereo listening (120Hz upper limit).

If you normally use all channels (eight channels for a 7.1 system, six for 5.1) then you will use either three or four P141 circuits, all controlled from a single 10k linear pot. This is the first multi-channel preamp that ESP has featured, for the very simple reason that until now there was no way I knew of to control the channels because of the difficulty obtaining multi-gang pots. Add poor channel-channel tracking (especially for log pots) and the tedious wiring involved, and you have far too many opportunities for wiring mistakes and/or general frustration.

This project relies on the excellent channel-channel tracking of the THAT2180 VCA ICs. As noted in the introduction, the performance is both extremely good and rather surprising. I never expected that the balance between any two 2180 ICs would be as good as it is, and until I was able to conduct tests I would never have thought to offer a preamp based on these devices.

This is an unusual project in many respects. However, it very neatly solves a problem for anyone who is interested in home theatre systems and also wants to use their system for music reproduction. It is not an inexpensive project, primarily because of the cost of the VCAs themselves, but the overall performance is very hard to beat. Distortion figures will never be as good as you'll get from decent opamps, but you'll never have a problem with a noisy pot, and you can control as many channels as desired with ease.

At most settings that will be used and with typical input and output voltages, distortion is mostly below 0.01%, and it only becomes worse at very low gain settings where noise affects the distortion reading. In short, performance is extremely good across the audio band, and you even get to choose the amount of distortion you think you can tolerate.

Of the three variants, the 2180B represents the best value for money. Quoted distortion (using the test conditions described in the datasheet) is 0.02% (maximum), and is primarily second harmonic with no evidence of many high-order components. The sixth harmonic is visible in the distortion chart ... at about -120dB, but above that there's nothing visible. I don't have the equipment to verify this, but nor do I have any reason to doubt the figures.

As noted at the beginning, PCBs are available for the project. See the Price List for the details.

Main Index

Main Index

Projects Index

Projects Index