|

| Elliott Sound Products | Traditional Fluorescent Tube Lamps & Their Alternatives |

Main Index

Main Index

Lamps & Energy Index

Lamps & Energy Index

The traditional fluorescent tube lamp has been with us for many years now. Popular in offices, factories and shopping centres, they have reasonably high efficiency and are available in a wide range of colour temperatures. Many people hate them with a passion, but that's not going to make them go away. Because of a well proven track record showing extremely high reliability and long lamp life, they will remain popular for many years to come. Or will they?

The standard 18 and 36W tubes (600mm / 2' and 1,200mm / 4') are now under serious threat. The new T5 tube is designed to use an electronic ballast, but unlike CFLs, the ballast is not thrown away with the tube - it's reused until it fails. The neon starter that's needed for iron-core ballasted tubes is no longer needed, and because the power requirement is reduced compared to a T8 tube, we can get the same (or more) light with less power. The T5 tubes still require the heater at each end, so an old tube is easily recognised by the blackened end where filament material has evaporated and adhered to the inside of the tube. Like any fluorescent lamp, they also require mercury to function. This means that disposal must be handled properly, with the right handling procedures and mercury reclamation to prevent toxic mercury from accumulating in landfill.

The latest challenge is LED tubes, and these go a step further. Power requirements are reduced even more, and the latest generation have very high light output with almost no heat at all. Having had the opportunity to test one recently, I am able to provide some measurements and comparisons between a traditional T8 tube, the newer T5, and now the LED Tube Light™

The size of fluorescent tubes is largely historical. It is based on the diameter of the tube, measured in units of 1/8 inch. Thus, a T8 tube is 8 x 1/8 inch diameter ... one inch (25.4mm). Likewise, a T5 tube is 5 x 1/8 inch, which is 5/8" or 16mm. The LED lamp I tested is approximately a T9, being 29mm diameter. This is a little unfortunate, as it limits the number of fittings that can accommodate the tube. It simply won't fit into two slimline self-contained fittings I have, but normal full sized fittings are not an issue.

For the series of tests performed, I used the lamps that I have available. I didn't purchase anything new, so the lamps tested are various ages. The conventional T8 fluoro is probably a couple of years old, the T5 electronic ballast lamp is a conversion kit, designed to allow the T5 lamp to be used in a T8 fitting. The LED Tube Lamp™ is new, having been given to me for test and evaluation.

All lamp voltages and currents were measured using my power meter, and waveforms were captured on a PC based add-on oscilloscope unit. Where appropriate, RMS voltages and currents were verified by my digital oscilloscope and true RMS multimeter - no significant discrepancies were found. The power readings obtained are both true power (Watts) and calculated reactive (or 'apparent') power, determined by multiplying the RMS voltage by the RMS current. This is VA (Volt Amps), and may be referred to on an electricity bill as kVAr (kVA reactive).

While reactive power is applicable to reactive loads (such as magnetic ballasts), it's really a misnomer for non-linear current waveforms. While an inductive current can be compensated by adding capacitance, non-linear current cannot be changed so easily. The issue of power factor (PF) is very complex, and harmonic currents caused by non-linear loads are becoming a major problem for power distribution.

An ideal load is fully resistive, so current and voltage are not only perfectly in phase, but have identical waveforms. Incandescent lamps, resistance heaters (electric radiators, toasters, electric blankets, etc.) are pure resistance for all intents and purposes. The reactive current in all of these is negligible, and can be ignored from a power distribution perspective.

This is not the case with any product that uses a switchmode or other non-linear power supply. These include computers, printers, compact fluorescent lamps (CFLs or 'energy saver' lamps), incandescent lamps used with electronic (phase controlled) dimmers, induction heaters, LED lamps and many, many others. While some of these products may include active power factor correction (PFC), the majority at present do not. Without PFC, the current waveform may well be in phase with the voltage, but being non-linear it creates a very poor power factor to the electricity grid. Unlike simple reactive loads, non-linear loads are extremely difficult to correct, other than at the load itself.

There is now a flourishing new industry providing mains filters that re-create a linear load to the grid, despite having a highly non-linear load current to customer equipment. This has become necessary because the higher than expected current drawn from the grid, replete with considerable distortion, is causing supply equipment failures and loss of capacity.

Consider a power factor of 0.5 as an example. This means that the equipment may draw 2 Amps, but only 1 Amp is used to perform useful 'work' (power). A domestic meter will register only the power - for 230V mains, this is 230W. However, the apparent power is 2A x 230V = 460VA, and the power grid must supply the full 2A. Multiply this by thousands of similar loads, and it's readily apparent that a 1MW distribution system can deliver only 0.5MW into an overall load having an 0.5 power factor. Half the total capacity cannot be used because of the higher than necessary current that is being supplied.

All commercial and industrial installations include metering that measures both real and apparent power, and excess apparent power is billed to the customer. While most household meters (at least in Australia) don't measure VA, this will change. When it does change, individual households may also be charged for excess 'reactive' (actually non-linear) power, so appliances need to meet an acceptable minimum power factor figure. This is typically around 0.9, and very few of the non-linear loads we have at present even come close.

However, all is definitely not lost. Advances in electronic PFC are progressing in leaps and bounds, with better performance and lower cost systems being produced at very regular intervals. It will soon be a non-issue, but only if people get serious about the alternatives. The current crop of CFLs are built to a price, and it's a rather unrealistic one at that. In order to compete with incandescent lamps, the price is far too low to allow anyone to produce a high-performance product that not only lasts as long as expected, but has a good power factor. Most are around 0.5 - this is quite unacceptable except if used in small numbers.

Where applicable, ballast power loss was calculated, based on the RMS current and the resistance of the ballast windings. The losses are almost all due to the resistance of the winding. There is also a small 'iron loss' component, but this was ignored since it is normally much lower than the copper loss in a fluorescent ballast.

While they have been with us for many years, fluorescent lamps remain somewhat mysterious to most people. This isn't really surprising, since their operation isn't simple. The tube itself contains a mixture of gases, but the active ingredient is mercury. When operated as an arc, mercury vapour emits a vast amount of short-wave ultraviolet light. This is invisible, but phosphors on the inside of the tube itself fluoresce when struck by UV, and are designed to emit visible light. Most of the remaining UV light is absorbed by the glass, which is opaque to ultraviolet (this is why you can't get a suntan from behind a glass window). Refer to Figure 1 to follow the explanation. This also shows a representation of the fitting that was used for the illumination tests. For all tests, only the centre tube was installed, with the others removed to ensure that each lamp was operating under near identical conditions.

Figure 1 - Wiring Diagram For a Conventional 'Troffer' (Fluorescent Light Fitting)

In order to start the arc inside the tube, a starter is used. This is a small neon lamp, with a bimetallic strip contact mechanism built in. When power is first applied, the neon conducts a small current - enough to heat the bimetallic strip, and this causes the switch to close. Once closed, current flows through the filaments at each end of the tube via the ballast, bringing them to working temperature. The ballast limits the current to a safe value. The filaments themselves are fairly rugged, and are typically around 2 Ohms resistance each.

While the switch in the starter is closed, there is no current flow through the neon gas in the starter. The bimetal strip cools and the contacts open. When current drawn through an inductor is suddenly interrupted, a high voltage is generated as the magnetic field collapses. This high voltage will (hopefully) strike the arc in the tube. As most people will have noticed, fluoros usually flicker a few times when turned on. This is usually because the initial strike is insufficient to maintain the arc because the gas temperature is too low. After a few strikes, the temperature is high enough that the arc maintains itself. Maximum light output is usually not achieved for around 5 minutes, but the difference is not very noticeable with tubes in reasonably good condition.

Once the arc is struck (and maintained), the ballast has a new task. An arc has negative resistance, so as the voltage across the tube falls, the current increases. The ballast limits the current to a safe value, as determined by the tube's ratings. With a continuous arc, the voltage across the tube is too low to allow the neon gas in the starter to conduct, so the starter is effectively bypassed. Old tubes will often be unable to maintain an arc, and this is why they flash and flicker, with the starter constantly opening and closing because the arc is not self-sustaining. Since AC is applied to the tube, the arc actually stops and re-strikes on each half cycle, causing the light to flicker at 100 (or 120) Hz. This is normally not visible, but a tube at the end of its life may only conduct fully in one direction. This causes a 50/60Hz flicker that is often visible and annoying to some people.

Because the ballast is an inductor, it should dissipate no power, but this can never be the case in reality. Inductors are wound with copper wire, which has resistance. If nice thick wire were used, this resistance could be minimised, but to do so is very expensive. A compromise is reached where ballast losses are deemed 'reasonable', and cause the temperature rise due to power loss to remain within allowable limits. New regulations will soon specify the maximum allowable power loss in ballasts, which will see a return to larger (and more expensive) types than we commonly see today.

Finally, a capacitor is (or should be) installed in parallel with the incoming mains. This is sized to suit the ballast inductance and supply frequency. The capacitive reactance of the PFC (Power Factor Correction) cap should exactly balance out the inductive reactance of the ballast. If this is done properly, the power factor will be 1 - a perfect result. This cannot happen with a fluorescent lamp though, because the current drawn is not linear. The voltage across the tube is a reasonable approximation to a squarewave because of the arc characteristics, and the maximum achievable power factor is normally around 0.9 (90%). Typical fittings manage 0.85 or so (some are better than others).

This means that the current drawn from the mains will be 10% higher than necessary to produce the lamp's rated power. This means that for a 36W fluorescent lamp, the minimum attainable current will be around 190mA at 230V because of ballast losses. The ideal current (if power factor correction were perfect) would be 174mA, allowing for a total typical load of 40W.

Figure 1A - Wiring Diagram For a 'Lead-Lag' Fluorescent Fitting

For many commercial and industrial installations, the 'lead-lag' circuit shown above is common. By including the power factor correction cap in series with one of the ballasts, the power factor is brought to around 0.85 as with the approach shown above, but the capacitor is smaller and thus cheaper than would be the case if the ballasts were in parallel.

Note that where 120V (60Hz) mains voltages are used, you may find that ballast is actually an auto-transformer. This is used because the voltage is not quite high enough to ensure reliable operation, and the auto-transformer configuration boosts the voltage. Figures 1 and 1A are for fittings operating from 220-230V, which need no voltage boost for normal operation. Predictably, the circuits for auto-transformer ballasts are different from those shown here, but similar techniques are used.

For this series of tests, I used a T8 fluorescent lamp with a conventional magnetic ballast, a T5 tube with electronic ballast and the latest acquisition, a LED Tube Lamp™. The ballast I used for the tests that follow is a really old one, with more iron and copper than is used in the latest generation (in the interests of economy - to build, not to run). Measured inductance is 1.15H but in reality it's probably closer to 2H (ballasts are hard to measure accurately because they are so lossy), and measured resistance is 32 Ohms when cold. After 1 hour, the ballast resistance rose to 35.2 Ohms.

With this ballast, 2.8uF in parallel with the lamp circuit will produce an overall power factor of at least 0.9 - while less than perfect, this is a good result. The measurements taken are tabulated below. All figures are taken at 50Hz, and voltages and currents are measured with a true RMS meter. Light output was measured with the lamp installed in an overhead fitting, with the tube under test in the same position (it's a 3-tube reflector fitting). The measurement distance was 850mm.

Because I don't have the necessary equipment, I was unable to measure luminous efficacy (lumens/Watt), but I did determine the lux per Watt at the workbench surface. While this is an unconventional measurement, it gives a good comparison between each tube light.

All the following graphs were captured using a PC based oscilloscope from tubes operating as described. Voltage waveforms are shown in red, and current in green. Measurements were taken using a Yew power meter, as well as a mains current monitor and a Tiepie PC oscilloscope. The waveforms shown are not doctored in any way, but were converted to a more visually friendly format for display. In all the following graphs, voltage waveforms are shown in red, and current in green.

A conventional T8 (25mm) x 1200mm 'cool white' fluorescent lamp was the first test. The measurement results are tabulated below, and show that the rated power is very close to the claimed figure. The power factor is lower than expected because the test was performed without a PFC capacitor as explained below.

Input Voltage 229 V Current 0.355 A (355 mA after 30 minutes) Total Power 37.8 W Volt-Amps 81 VA Power Factor 0.466 (no capacitor) Ballast dissipation 4.4 W Light Output 310 Lux Lux / Watt 8.2

This is a fully expected outcome. Although the light level may seem low, for indoor use it's not - there's a lot more light from a 36W fluorescent lamp tube than a 100W incandescent lamp for example, and it's distributed over a wide area. This reduces shadows and improves the overall lighting to a good dispersed light pattern that approximates that found outdoors in 'cloudy-bright' conditions (but at a much lower level).

Figure 2 - Current & Voltage Waveforms, T8 Conventional Fluorescent

This test was deliberately run with no power factor correction capacitor so that the lagging current is clearly visible. The phase lag is about 46°, and the recommended 2.8uF capacitor will bring the overall power factor back to at least 0.9 - a realistic minimum for commercial or industrial usage.

Figure 3 - Voltage Waveform Across T8 Fluorescent Tube

The voltage waveform directly across the tube was also measured. As you can see, it's pretty close to a squarewave, but is modified somewhat by the negative impedance characteristic of the mercury arc.

Of the power applied, 4.4W is completely wasted as heat in the ballast. Newer ballasts may waste anything from 8-12W as heat because they are smaller and made much more cheaply.

In Australia, this is about to change because fluorescent ballasts are being subjected to the MEPS (Minimum Energy Performance Standards) regime. This can only be seen as a good thing, since the wasted energy in a cheaply made high resistance ballast becomes a real problem when you consider that a single medium sized office building or a large supermarket or shopping mall may have several thousand lamps operating for at least 12 hours a day, every day.

If each ballast wastes (say) 10W and there are only a thousand of them installed, that's 10,000W (10kW) wasted energy. In terms of overall cost, that's as much as 100kWh of wasted energy every day - multiply that by the number of offices, shopping centres etc. in your area and the number gets very scary very quickly. Most households would use only a fraction the energy that's wasted by 1,000 fluorescent lamps with low efficiency magnetic ballasts.

Note: As stated above, the test was performed without any PFC capacitor installed. It must be clarified that installing the cap reduces the current drawn from the mains, but has no influence whatsoever on the current through either the ballast or the tube. This means that even though the mains current can be reduced considerably by adding the PFC capacitor, the tube current will still be 355mA as measured and ballast losses remain the same. While this might seem like an impossibility, it is completely real and relatively easily explained.

When the ballast is functioning in conjunction with the fluorescent tube, it is largely inductive, so is an energy storage device like all inductors. The tube is a crude switch, so the combination acts as a very basic switchmode converter. Since the voltage is being reduced to suit the tube, the overall applied current after power factor correction is reduced. This is no different from any other switching regulator. The reduction of voltage allows a transformation of current, so with 230V input and a typical voltage across the tube of 107V RMS (as measured), the voltage transformation ratio is 2.15:1 (this assumes a lossless ballast for simplicity of explanation).

If everything were perfect, the current would be reduced by the same amount, so 355mA will be reduced to 165mA. No laws of physics or thermodynamics have even been bent - 230V at 165mA is just under 38W, and 107V at 355mA is exactly the same. Because the ballast has resistance and the current waveform is non-linear, these ideals cannot be met, but the principle is unchanged.

I also tested a new style slim-line surface mount fitting. As expected, the ballast resistance is much higher than the old one I used for the other tests. I used exactly the same tube as used for the test above for the measurements. I also tried a brand new tube, and found that there was less than 1W difference in power consumption, so the age of the tube is of little consequence - within reason. The test results are shown below for reference (no additional waveforms were taken, as there is little point).

The ballast resistance was measured at 48 Ohms when cold (~15°C) and 60.4 Ohms when hot (68°C). Inductance was not measured.

Input Voltage 221 V Current 0.338 A (358 mA after 30 minutes) Total Power 40.8 W Volt-Amps 79.1 VA Power Factor 0.51 (no capacitor) Ballast dissipation 7.74 W

The ballast is made in Europe, and has CE, VDE and Australian approvals. The fitting is classified as 'low power factor' which is certainly true, and no PFC capacitor is fitted. There is a 47nF 275V AC rated capacitor directly across the mains, but this is for EMI (Electro-Magnetic Interference) suppression. It has no effect on the power factor.

In case you are wondering why this ballast gives a marginally better PF than the old one I used for the main tests, that's because it has more resistance. The extra resistance in the circuit reduces the phase lag of the current waveform slightly, and thus improves the power factor. Given the stupid power loss in the ballast - sufficient to cause a temperature rise of over 50°C - the marginal improvement in PF is pointless. The ambient temperature is about 15°C in my workshop, and the ballast temperature was measured at 68°C after a couple of hours operation. Almost 8W applied to the fitting is wasted as heat, and performs no useful work whatsoever. At higher ambient temperatures the power loss will increase, and 10W is not an unrealistic estimate of the average loss.

You may have noticed that the current drawn increases when the ballast gets hot and its resistance rises. This is not an error or misprint, but is a real phenomenon. Refer to the note (above) explaining the transformation that takes place between the inductor and lamp. If more voltage is lost across the ballast's resistance because it increases, then the transformation ratio is affected, so current must rise to compensate. It would not be useful to explain the process in full here, as it is fairly complex and will not change anything. However, it does show quite clearly that a low efficiency ballast wastes more power than you might imagine.

An electronic ballasted T5 tube was next - the colour temperature is not stated, but would appear to be around 3,500K. This tube gives a very good account of itself. Power is reduced from a standard tube, and when operated as recommended the power factor is excellent. The only down-side to a retro-fit is that any PFC cap that's installed in the fitting should be removed to prevent an overall leading power factor in large installations.

Voltage 227V Current 141 mA Total Power 30.7 W Volt Amps 32 VA Power Factor 0.96 Ballast dissipation 0.64 W Light Output 410 Lux Lux / Watt 13.4

The T5 tube is obviously more efficient than a standard tube. The light quality is virtually identical and there's more of it, but wasted power is reduced. Power factor is extremely good without any requirement for a PFC capacitor. There is no flickering when the lamp is turned on - light is immediate and at a good intensity right from the start. Like all fluorescent lamps, the light level increases to its maximum over about 5 minutes as the lamp reaches operating temperature, although the visible difference from cold is not very pronounced.

Figure 4 - Current & Voltage Waveforms, T5 Fluorescent

It is recommended that the unit I have be operated with the ballast installed, so that's what was done. The voltage and current are closely in phase, and the power factor measured 0.96 - a very good result.

Because the T5 electronic ballast is essentially a switchmode power supply (SMPS), the flicker frequency of the lamp is much higher than the normal 100Hz (or 120Hz for 60Hz mains). The claimed operating frequency is 28kHz, and I measured the flicker frequency at 29.5kHz. High frequency operation is preferable for all fluorescent lamps, as the phosphor efficiency is increased by raising the frequency.

The results for this lamp are excellent in all respects. The tube I have is rated for a colour temperature of 6,500K which is very harsh, and probably accounts for the much higher measured light output. LEDs lose efficiency as their colour is made 'warmer' (i.e. a lower colour temperature), but this lamp is so efficient that losing a bit of light isn't really an issue. These lamps are currently available with colour temperatures of 3,500K, 4,500k and 6,500K.

Note that the unit described here is several years old, and the latest tubes are far better in all respects. Power is generally a little higher, but light output is far greater than the 'first generation' LED tube lights. There are several models now that boast light outputs of around 80-90 lumens/ Watt, and they keep getting better.

LED Tube Light (Ballast In-Line)

Input Voltage 225V Current 85mA Total Power 15.7 W Volt Amps 19.125 VA Power Factor 0.82 Ballast dissipation 0.25 W Light Output 470 Lux Lux / Watt 29.9

At more than twice the light per Watt, the LED lamp is a clear winner. While its power factor is not quite as good as it should be for commercial/industrial use in vast numbers, the current draw is so low that this is not a major concern. The main issue that power utilities would be unhappy about is the non-linear waveform, which creates power line harmonic currents. These are becoming a major issue in the power grid, however this can be solved relatively easily.

Figure 5 - Current & Voltage Waveforms, LED Tube Light™

Although the LED fluoro replacement is recommended for use without a ballast, I took the first measurement with the ballast installed. It turns out that this is preferable, because it improves the power factor. As you can see from the above, the current waveform is in phase, but is still non-linear. However, at a measured PF of 0.82 it is very suitable for domestic installations. The power factor needs to be increased to at least 0.9 for large installations, but even if this is not done, the power drawn is still a great deal lower than a conventional fluorescent lamp or the T5 lamp with electronic ballast. The figures measured are ...

Voltage 229 V Current 92 mA Total Power 15.1 W Volt Amps 21.1 VA Power Factor 0.717 Light Output Not measured

The only significant difference between using the LED light with or without a ballast is the power factor. There is also a very small loss (0.25W) in the ballast - this will be higher with modern (cheap) ballasts, but can be expected to remain well below 1W, even if the resistance is far higher than the one I used. The biggest disadvantage is the non-linear current waveform, which is made much worse without the ballast in circuit.

If this lamp were used with the modern ballast used for the second T8 test, the wasted power will be about 0.32W. This is very low, and easily tolerated even for a very large installation. In general, I'd recommend that the ballast be retained, and with this lamp low efficiency ballasts will still have extremely low dissipation because of the low current drawn.

Figure 6 - Current & Voltage Waveforms, LED Tube Light™ (No Ballast)

Without the inductive ballast installed, the current waveform has the expected spikes as the voltage waveform reaches its peak. With a measured PF of 0.72 it's not wonderful, but remember that this lamp draws a rather measly 92mA even without the ballast (which reduces the current to 85mA). Compare that with the magnetic ballast and standard tube at 355mA or the T5 with electronic ballast at 141mA and it's still a bargain.

Naturally, all is not completely 'sweetness and light'. A conventional fluoro tube emits light around all 360° of its circumference, much of which often isn't used usefully. The LED tube has a much narrower angle, and its light is aimed directly downwards where it's needed. If a T8 or T5 tube is installed in a fitting that has a very good reflector it will beat the LED tube for total light output. When I replaced a standard 36W tube above my desk with a LED lamp, the desk area is illuminated just as well as before. However, the remainder of the room is darker, because the 270° coverage of the fluorescent lamp is no longer available (the full 360° isn't available because of the fitting itself). Most of the time, this is not an issue, and I now use 15W instead of 40W to light my office at night. My work area is well lit, and for the occasional task that needs it, I have always had a desk lamp to augment the overhead fluorescent fitting.

Some photos are in order, since few people have ever seen a retro-fit T5 kit, and fewer still will have seen the insides of a LED tube. These photos will give you an idea of what I have covered here.

Figure 7 - T5 Conversion Kit Contents

The T5 conversion kit (from left to right) consists of a tube end-piece to match the smaller T5 contacts to a T8 fitting, an electronic ballast which fits over the other end of the tube, and a 'special' starter. The starter is actually a fuse. This is needed to complete the filament circuit, which is permanently connected to the ballast electronics. The same connection scheme is used with CFLs. T5 tubes are 1,105mm long, and the ballast and end-cap allow the tube to fit into a normal T8 lighting fixture.

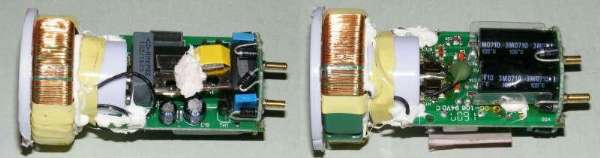

Figure 8 - T5 Switchmode Power Supply

The power supply itself is well made, using fibreglass printed circuit boards. It is very compact, but since nothing gets more than slightly warm in operation the close-packed parts aren't a problem. The components are a mixture of through-hole and surface mount. The second pic is a view of the other side of the supply. The large coil on the left side is the transformer that's needed to produce the different voltages for the filaments and the tube arc. Unlike most of the CFLs I've seen, all parts are properly rated for use on 230V AC mains, and spontaneous failure is far less likely.

Not quite so happy with a different version of T8-T5 converter. The principle is great, and they look a lot better than those shown above, but one of the two I got flickers (only a bit though), and makes noise (intermittent buzzing sound). The reflector fitted throws all the light where you need it, but this may be somewhat overpowering. Fortunately, the reflector can be removed, although this was not mentioned anywhere.

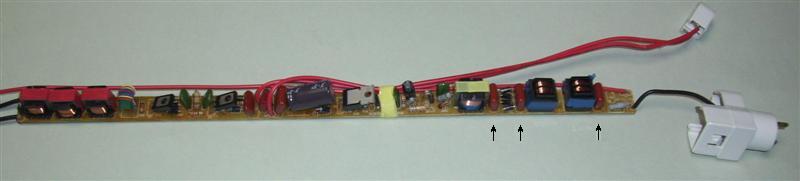

Figure 9 - T8 - T5 Converter Switchmode Supply

I recently obtained a couple of these converters. These are full length, and the body of the unit has the standard T8 connectors on the ends, with added (and smaller) tombstones for the T5 tube. These are available both with and without reflectors. There are many examples to be seen on the Net, but you won't get to see the insides until you buy one and pull it to bits.

I'm rather disappointed with the quality of these particular units. The underlying circuitry looks alright (active PFC, high efficiency, etc.), but the parts quality is sadly lacking. The 400V DC caps that are used will fail with 230V AC mains, and the power supply PCB is definitely made on the cheap. I don't expect that all are the same, but there's no way to know for certain - major brands may or may not be better. Note the orange capacitors at the right end of the board (highlighted by little arrows). Two of these are subjected to the full 230V AC mains voltage, and the third is subjected to the full-wave rectified AC waveform. All 3 are only rated for 400V DC, and this is simply unacceptable.

Overall though, I would recommend this conversion if you can find a good quality conversion kit. T5 fluorescent lamps have higher luminous efficacy than T8 types - partly because of the high excitation frequency. As with the other version shown above, power usage is considerably lower than a magnetically ballasted T8, and power factor is improved quite dramatically. Provided you can find a well designed unit, with a good circuit and properly rated components, this is a cheap and effective way to get more light with less power. Unfortunately, I'm in no position to make a specific recommendation - there are too many variables and the ordinary user is in no position to evaluate the circuitry. The best I can recommend is to use converters from suppliers who are willing to provide good (and specific) details about their products, or who offer a long warranty period (and will actually honour the terms of the warranty).

I must mention a caution regarding T5 fluorescent fittings (that is to say complete fittings, rather than converter systems). Some are fitted with magnetic ballasts, and they perform very poorly compared to a fitting with an electronic ballast. Some I have seen are worse than a traditional T8 tube with a magnetic ballast. Unless the packaging clearly states that an electronic ballast is used, don't buy it, as you will be disappointed with the light output and the tube life. IMO, this is just a scam by suppliers who think that the general public won't know the difference. Unfortunately, they are right.

LED tube lights have really come of age lately. The unit shown below (and the test results) are well out-of-date, but are still relevant. There have been many changes in the last couple of years, in all cases improving safety, light output, power factor and overall efficiency.

Figure 10 - LED Tube Light™ Switchmode Power Supply

The SMPS (switchmode power supply) for the LED lamp is also very nicely made. Again, there is a mixture of through-hole and surface mount parts, and good quality components have been used. The circuitry on this board is very simple. and the main IC (which has all traces of part number removed) is something fairly clever (it's a LinkSwitch IC). There are no parts on the underside. This photo was taken of a lamp that had been broken - I didn't bust the one I was given apart just to take photos.

Figure 11 - LED Tube Light™ LED Array (Part Only)

Here we can see a small section of the LED array that is used. A 1,200mm (4') tube has 276 LEDs in all, mounted on two boards joined in the middle. This is almost certainly done because a 1,200mm PCB is rather unwieldy and easily broken. The 600mm tubes have 174 LEDs. The 1,200mm tube runs each LED at about 50mW, so individual LEDs run cool enough to need no heatsinking at all.

This table allows you to see the details of each lamp side by side to make comparison easier. The figures shown here are the same as those in the individual tables above. The second T8 lamp (marked with *) is using the same tube as originally tested, but in a new fitting with a much less efficient ballast installed. It is quite obvious that the efficiency needs to be improved dramatically, especially as the cost of electricity increases.

| Lamp Type | T8 Fluoro | T8 Fluoro * | T5 Fluoro | LED (Ballast) | LED Alone |

| Input Voltage | 229 V | 221 | 227 V | 225 V | 229 |

| Current | 0.355A (355 mA) | 358 mA | 141 mA | 85 mA | 92 mA |

| Total Power | 37.8 W | 40.8 W | 30.7 W | 15.7 W | 15.1 W |

| Volt-Amps | 81 VA | 79.1 VA | 32 VA | 19.125 VA | 21.1 VA |

| Power Factor | 0.466 (no cap) | 0.51 (no cap) | 0.96 | 0.82 | 0.717 |

| Ballast dissipation | 4.4W | 7.74 W | 0.64 W | 0.25 W | N/A |

| Light Output | 310 Lux | N/A | 410 Lux | 470 Lux | 470 Lux |

| Lux / Watt | 8.2 | N/A | 13.4 | 29.9 | 31.1 |

There is absolutely no doubt that the LED lamp has arrived. Most people will be deterred by the price, but will fail to see the bigger picture. At the time of writing, the cost of residential electricity in Sydney is about 15 cents/ kWh (as of 2012 this is now over 21c/kWh). At a recommended price of around $150.00 each (retail, one off price), the LED tube is expensive, but let's do a bit of basic maths. Remember too that these are early days for LED lamps, and the price will fall once production increases - expect somewhere between $40-60 (and possibly less) in a couple of years.

A conventional T8 fluorescent tube costs about $5.00 (for argument's sake). Assume a maximum life of around 10,000 hours, so the lamp will have consumed around 40W for this entire time (which may take many years in reality). This is 400kWh, and at 15c/kWh will have cost $60.00 to run.

A LED lamp running at 15.7W (let's say 16W) will use 160kWh at a cost of $24.00 - this is a big difference, and it's obvious that the LED tube only has to outlast 3 standard fluoro tubes before it's paid for itself. This is worst case ...

We haven't even considered the cost of a person to change the lamp (and usually the starter at the same time), which must always be considered in commercial applications, then there is safe disposal to add in - remember that all fluorescent tubes contain mercury, and must not be disposed of with normal (landfill) waste.

To my mind, there's simply no contest. At up to 100,000 hours claimed life (although most have revised this down to 50,000 hours), the LED lamp has the ability to last for over 11 years if operated all day, every day. Even half this (50,000 hours) is perfectly reasonable, and as the cost of electricity increases, the payback time gets shorter. In domestic use, lamp life could easily extend to 20 years or more with normal household or workshop use. For me and many of my older readers, a new LED lamp could easily outlive us. Imagine never having to replace a lamp for the rest of your life!

For a commercial application, consider a shopping centre with only 1,000 T8 tubes (this will be a fairly small mall). Each draws 40W, for a total of 40kW. Of this, well over 10kW is wasted as heat (from the tubes and ballasts), so the air-conditioning system can be expected to draw up to another 10kW to remove the extra heat. That's a total of 50kW, for at least 12 hours a day - 600kWh. At 15c per kWh, the running cost alone is $90 per day. (At 21c/ kWh, this rises to $126 a day.)

If LED tubes were installed instead, the lamps will use 15kW, and over the same 12 hours will consume 180kWh at a cost of $27 - a daily saving of $63 isn't peanuts. In the greater scheme of things it's only a small part of the daily running cost of a shopping centre, but by using less electricity the load on the grid is reduced too. Little or no additional air-conditioning is needed because the heat output is very low, and maintenance costs are reduced because the lamps last so long.

Now multiply the savings by the hundreds of office blocks, schools, factories, etc., etc. in even a small city and it is obvious that there are enormous savings to be made. Make no mistake, we need to make these savings, simply because we are running out of the resources that we use to generate electricity. The climate change debate is almost irrelevant - we can't keep doing what we've always done because we will no longer have the coal or gas needed to run existing power stations. This won't affect the current generations, but it would be polite to leave some resources for the future.

While the cost of LED lighting is certainly a deterrent at present, this will fall as the cost of electricity inevitably rises. Even at current prices, the LED tubes will pay for themselves very quickly in commercial applications, but they are unlikely to see wide acceptance in domestic installations until prices come down to levels that householders will see as 'reasonable'.

Note: One point must be clarified here. If one looks at the total lumen output from a fluorescent tube, it is considerably higher than that from the LED tube. All fluorescent tubes radiate light for 360° around their circumference, but some of this light is simply lost. If the troffer (fitting and reflector) is old, faded yellow or (very) dirty, it will reflect very little light, so only the light that radiates downwards is useful. Normally, to regain the maximum light, one would need to re-finish the reflective surface or replace the troffer - these are expensive options.

Because the LED tube presents maximum light directly downwards where it's needed, the reflective surface is of no consequence, so it will have a higher light output. This is the reason that I measured more light from the LED tube in the fitting above my workbench - the fitting is old, and the shiny white enamel ceased to be shiny or white even before I acquired it. Because of this, the LED tube was able to do what the fluorescent tubes can't - project the maximum amount of light right where I need it.

If LED tubes are installed in brand new reflector troffers or other fittings, you will experience slightly less light than that from a fluoro. Since most new installations will use T5 tubes and will have nice new reflective surfaces, a direct comparison will show the LED tube producing less total light. In 10 years or so (depending on where the fittings are installed), the reflective finish will have gathered dirt and may have faded to a dull yellow because of UV exposure. By comparison, if LED tubes were installed instead, the same total light output could be achieved by using (say) 3 tubes instead of 2. With a power consumption of 48W vs 60W and the likelihood of almost zero replacements over the 10 year period (vs ~10 new tubes for the T5), the LED tube installation is still ahead.

|

There are no references as such, because all figures quoted are based on direct measurements taken in my workshop. However, I must thank FLASH Photobition for the kind donation of the LED tube. This was the trigger for this series of tests, and has changed my opinion of LED lamps forever. I always knew that LEDs were the basis for the lamps of the future, but it is now quite obvious that the future is already here. |

Main Index

Main Index

Lamps & Energy Index

Lamps & Energy Index