|

| Elliott Sound Products | Voltage & Frequency |

Main Index

Main Index

Articles Index

Articles Index

Initially, it all seems simple enough. You buy a piece of equipment from an on-line seller in another country, and expect that it should have the necessary switching to allow you to set the voltage to suit the mains supply where you live. With globalisation being the key term thrown around these days, you'd naturally expect that there should be few (if any) problems.

If the country you bought the gear from is Australia, Europe or the UK (but the equipment was built elsewhere) you might get lucky, but if it's equipment that's made in the country of origin you may not. Buying from the US or Canada will often cause problems, because the 'export model' is generally not sold locally, so it will be made to operate only with the US mains voltage and frequency.

While the common answer is to just get a step down transformer to reduce your local mains (say 230V) to 120V, this may not solve the problem at all, and may introduce serious safety risks as well as the possibility of transformer failure. Unfortunately, the simple (and common) answer fails to consider many different possibilities, some of which may place the user and/or the equipment at considerable risk. One of the most common requirements is that people want to be able to use equipment from the US in Australia, Europe, etc.

The step-down transformer is not straightforward, although it initially seems that nothing could be simpler. Very few people seem to appreciate the various things that can go wrong, even those with technical training. 'Information' from forum sites is almost always either wrong, overly simplistic or misguided. A small number of forum posters will understand the risks, but it's impossible for the average person to determine who is right and who's not.

Voltage can be very confusing. There are so many different standards worldwide, and most people are unaware that the quoted voltage is nominal. It can vary widely from that claimed and depends whether you are in the city, close to an industrial complex, near a distribution transformer, in a rural area, etc., etc. In Australia we used to have 240V, but that was 'changed' to 230V, except that for most installations nothing changed at all. Much the same has applied in other countries - especially the US.

US mains voltage is regularly stated to be 110V, 115V, 117V and 120V. Various changes over the years have occurred, and the nominal voltage is supposed to be 120V. Don't be at all surprised if you measure any or all of the voltages quoted ... at the same wall outlet but at different times of the day! This is completely normal.

The mains in much of Europe used to be 220V, but is now claimed to be 230V, and fluctuations are just as common there as anywhere else. The mains voltage in many countries outside of the so-called developed nations can often be an even greater lottery, and even Japan has dual standards - 100V, at a frequency of 50 Hertz in Eastern Japan (including Tokyo, Yokohama, Tohoku, Hokkaido) and 60 Hertz in Western Japan (including Nagoya, Osaka, Kyoto, Hiroshima, Shikoku, Kyushu). It may be claimed that "this frequency difference affects only sensitive equipment". The frequency difference can be highly significant - the above statement is a gross over-simplification. This is covered in more detail below. So, voltages worldwide vary widely [1] and you will rarely measure the claimed voltage.

Unfortunately, many people will buy equipment first, assuming that conversion is 'easy'. Without conducting tests, it's actually very difficult to be certain that a conversion will work at all. US (60Hz) equipment may or may not work with 50Hz mains, and it is usually impossible to find out unless it's tested at the lower frequency, or someone else with an identical piece of kit has posted factual information about the end result. Information is everywhere, but a significant amount is not associated with reality.

The first thing that you need to determine if whether the voltage needs to be increased (step-up) or decreased (step-down). The latter is more common, but if (for example) European equipment is to be used in the US, a step-up transformer will be needed. Many European made goods (or goods intended for Europe) include multiple voltage selection, but some don't. Some new equipment uses an auto-ranging switchmode power supply. These can generally work with any mains voltage from 100V or less up to 240V without need for adjustment - but not always!.

Where it is decided that a step-down (or step-up) transformer is required, these are generally available with a limited number of output voltages - usually one!. While this might be alright with goods intended for Australia/NZ, Europe or the UK, you might run into problems with equipment designed specifically for the US domestic market. The reason for this is rather obscure, not well understood by most people, and is explained below. The problem is frequency!

Not all transformers are created equal, and even those that seem to perform exactly the same task can be very different. With on-line auctions, equipment made at rock-bottom prices in Asia, uneducated sellers who don't actually understand what it is they sell or how it might be dangerous, and you have a potentially lethal mix.

Ideally, a step down transformer will use separate windings for the primary (typically 230V) and secondary (120V). The protective earth connection will be continuous, right from the 230V plug through to the transformer case and then to the 120V outlet(s) provided. The primary and secondary windings are separated electrically, and a test with an ohmmeter will indicate that there is no electrical connection between the two windings.

A complete wiring diagram is shown in Figure 1, and by using separate windings there is an isolated and comparatively safe secondary winding. This is extremely important if you purchase vintage US electronic equipment that happens to use a 'hot chassis'. This term refers to gear that does not use a mains transformer of any kind, and simply connects directly to the mains. This often meant that the chassis was live (connected directly to the mains active). With 120V gear and a bit of insulation this was considered 'safe'. As Arthur Dent said in Hitchhikers' Guide to the Galaxy "Ahhh. This must be some strange new meaning of the word 'safe' that I was previously unaware of." (Or words to that effect.)

Figure 1 - Properly Wired Step-Down Isolated Transformer

The diagram above shows the only genuinely safe form of step down transformer. The isolated windings mean that no part of any insulation designed for 120V can be subjected to 230V (or more). While the fuses shown are not strictly needed in both primary and secondary, they are cheap insurance. Ideally, the transformer will also be protected by a thermal switch that will remove power if it gets too hot. While electronics engineers, technicians and some enthusiasts will - hopefully - always make sure that the load is appropriate, the general public will not. It's not their fault - how is someone who knows nothing about electricity going to understand what VA means? Do you know what it means? If not, I suggest that you read the beginners' articles on transformers.

Compare Figure 1 with an autotransformer as shown in Figure 2. If wired correctly, these are a much cheaper (and usually smaller) alternative, and they are generally 'safe' (using the "strange new meaning" described above). There is a problem though, being that the primary and secondary are one and the same - the low voltage is simply a tapping on the main (primary) winding. Autotransformers are smaller, lighter and usually cheaper than an isolation transformer, so people like them. An autotransformer has a direct electrical connection (of usually only a few ohms) between the high and low voltage sections - there is NO isolation whatsoever.

There is some doubt as to their legality if sold as an appliance in their own right - in Australia an autotransformer cannot be certified because there seems to be no classification. In Europe they may very well be an illegal appliance, but they are sold anyway, especially at on-line auction sites. The situation will vary from one country to the next, but potentially lethal models can be purchased on-line from anywhere in the world. In industrial applications auto transformers are common, but they are a fixed installation and not little boxes that anyone can use with a home appliance.

Until some form of global certification scheme exists that describes (and enforces) what can and cannot be done, anything is possible. There are real dangers with auto transformers when used as a stand-alone product, and IMO they should be banned worldwide. I do not recommend that anyone wait for such regulations - it may never happen.

Figure 2 - Properly Wired Step-Down Autotransformer

While an autotransformer may be considered 'safe' if properly wired, there was a tale (including photos) in a local electronics magazine (Silicon Chip, February 2010 issue), where auto transformers sold on a well known auction site are not only wired incorrectly, but are not even earthed. The transformers in question are rated at 300VA, and the active lead was common to both input and output as wired. This wiring is potentially lethal, and these transformers have no Australian approval markings and are potentially deadly. I filed a report for the listing ... no action was taken.

The biggest problem is that you usually don't know what you're getting until it's too late. If the seller doesn't understand the difference between a transformer with isolated windings and an autotransformer, then asking the question won't help at all. If the item was made in Asia, then all bets are off - it may be 100% ok, or it may be incorrectly wired, dangerous and illegal. If a supplier cannot tell you for certain that the transformer is an autotransformer or uses separate windings, don't buy it! If the seller doesn't know, and doesn't know how to find out, then s/he has no business selling the product.

In general, I strongly recommend that any step-down transformer used should use isolated windings (Figure 1 arrangement). At least one fuse is mandatory, and the mains input plug must not be the same as the output socket. If the seller doesn't know what kind of transformer is used - go elsewhere. Safety comes first, and auto transformers are not safe for use by the general public - especially with equipment that may have a live (hot) chassis. This was very common with vintage US made equipment - including some small guitar amplifiers!

An example is the Kay 703-C vintage guitar amp. Although the schematics I've seen show an 'isolation transformer' it's no such thing - it's only a filament transformer for the first valve. 'Isolation' is afforded by a 47k resistor bypassed by a 500V DC capacitor (which will fail with 230V applied). An amplifier like this, connected through a dubious autotransformer is a potential killer. Should the chassis (and therefore the earth of the input jacks) become live, you have 120V or worse - 230V - connected directly to the strings on your guitar via an internal connection in the guitar. If you now pick up a microphone, or touch some other earthed equipment, you are very likely to die right then and there. Alarmist? Not at all - this is very real !

Some transformers have 'universal' connectors that will accept US, European, Japanese, UK, Australian/NZ (etc.) plugs. While perhaps convenient, the legality of these connectors is dubious. They may also pose a significant risk if the transformer is a step-up type (120V to 230V for example), because they will accept a US style 120V mains plug. It is important that any transformer used has a 3-pin earthed output connector, as it is often a requirement (or at least desirable) to be able to use a proper 3-pin earthed (grounded) mains plug.

| Some transformers (seen for sale in Australia, but no doubt elsewhere as well) have both a 240V and 110V output at the front, with both using the same connector! This is asking for trouble ... a momentary lapse of concentration that causes your 120V equipment to be accidentally plugged into the 220/230/240V output may cause irreparable damage, well before any fuse or other protective device opens. This qualifies as an extremely bad idea, and such products should be avoided like the plague. |

To assure the safety of yourself and your family, any transformer you purchase should be checked by an electrician or qualified technician to ensure that it is properly earthed, is a true isolation transformer, and is likely to be able to provide the claimed power without overheating. Products purchased from reputable shop-front (not on-line) dealers are likely to be safe, but even this cannot be guaranteed.

Equipment that has any claims to audiophile status needs to be examined very carefully. Safety may be compromised in the interests of 'better sound' - although most such claims are utter nonsense. Your amplifier (and its internal electronics) have no idea if there is an external transformer connected, and provided the transformer is properly sized, the sound quality will not be compromised simply because there's another transformer in the circuit. A high price, silver wire and allegedly esoteric components do not mean that the product works any better or is any safer than something you can buy at an on-line auction for a fraction of the price.

These have exactly the same requirements and risks as step-down types. Again, both isolated winding and autotransformer types will often be available, and wherever possible the isolated winding type should be used. Outlets must be different from the normal power outlets that are used where you live to prevent accidental connection of 120V equipment to 230V. Any 230V outlet should always be a 3-prong type, with the earth (ground) pin connected to a secure safety earth.

US residents should avoid the temptation to use the commonly available 2-phase 240V connection. In some cases it may be illegal to use it for connection of foreign equipment. I also have personal experience with equipment designed for 220V that's operated at 240V - it often blows up! All internal voltages are higher than they should be, and some parts are not capable of withstanding the extra voltage.

It is far better to use a transformer that converts 120V to 230V to suit the manufacturer's rating on the equipment. There is nearly always a safety margin, but only around the nominal nameplate voltage.

Where a step-up transformer is used, some long-held habits may need immediate revision. I know that some people in the US use a 'finger test' to find out if a connection is live - it's a very bad idea, but the relatively low voltage means that electrocution is unlikely. This is absolutely not the case with 230V mains. This voltage is far more dangerous than 120V, and a simple finger test may prove fatal. Those who work with 220-240V systems all the time know just how dangerous it is, but if you're not used to it, extreme caution is essential.

One thing that residents of the US and Canada (or other 60Hz countries) don't need to worry about too much is the frequency. Any 50Hz equipment will run cooler at 60Hz and is not usually a problem - other than appliances that use induction motors!

A 50Hz 3,000 RPM motor will run at 3,600 RPM with 60Hz, and the same ratio applies for other speeds. This many cause potentially dangerous problems with many appliances, and in general cannot be recommended. Other motor types are usually not affected, but you may not know - nor be able to find out - what kind of motor is being used.

Although many sellers rate step-up or step-down transformers in Watts, this is incorrect. The correct term is VA - Volt Amps. Many typical loads may draw significant current, but the actual power (in Watts) may be quite low. It isn't possible to give any kind of definitive answer, since different products can vary widely. In general, it's safe to assume that the load will draw about half the load current as actual power, with the remainder as either reactive or non-linear current. This is the basis of power factor, but a detailed discussion is outside the scope of this article.

If we assume that the above is reasonably correct (it does err on the side of safety), then the maximum power consumption in Watts quoted for the equipment can be multiplied by two to give a safety margin. In reality, it is sometimes possible to use a step-down transformer that's rated for somewhat less than the maximum power for some audio equipment, but this relies on several things and has consequences ...

Although you may get 'advice' that this is perfectly alright, my recommendation is very simple ... DON'T DO IT. The only exception is if an experienced technician has examined and tested your imported kit and determined that nothing bad happens (or is likely to happen) under all probable operational conditions - including typical and/or atypical faults or failures. No sensible technician will generally be willing to be quite so rash, so my original recommendation should remain ...

An external step-up/down transformer should be rated for double the

maximum claimed power draw of the connected equipment

So, if your amplifier, CD player, kitchen blender, mixer, power saw, etc., etc. claims (say) 500W maximum power, use a 1kVA (1,000 Volt Amps) transformer. Yes, the transformer will be larger, heavier and more expensive, but it will also allow the appliance to operate as it normally would if connected to the design value of supply mains. The transformer's additional voltage drop will be small, and you have a safety margin that allows for power factor, momentary overloads and switch-on surge current (aka inrush current). The voltage to your appliance will be reasonably stable - not quite as good as if it were connected to the designed supply voltage, but reasonably close.

Using a transformer that is larger than that suggested will generally provide little or no additional benefit. The difference will be measurable, but it is unlikely to be noticed in use. This applies regardless of the type of appliance.

Now comes the real can of worms. Many people believe (and will tell you) that the small frequency difference (50Hz vs. 60Hz) is insignificant, but this is not true. Many products intended solely for the US markets will have the transformer made for 60Hz. This has the advantage of making the transformer smaller than it would be if it could also handle 50Hz. Indeed, an advantage of 60Hz mains is that all transformers and induction motors are smaller than the 50Hz equivalent. The alternative is that in some cases, a 60Hz and 50Hz transformer may be the same physical size, but a 60Hz only version can use lower grade (and therefore cheaper) steel laminations.

If a transformer is designed specifically for 60Hz, and understanding that this makes for a smaller and/or cheaper transformer than would be the case if it could also handle 50Hz, why would anyone assume that this 60Hz tranny will work fine at 50Hz? The answer (predictably) is that it will not. An initial quick check will usually not show the problem ... it may need to be left on for a while before anything shows up. The problem is heat - the transformer will get (much) get hotter than normal, and may easily reach a dangerous temperature that will cause failure.

Some years ago, a company I worked for (in Australia, a 50Hz country) took delivery of six very large and expensive 48V power supplies for telecommunications use. These were made in the US, and used ferro-resonant transformers that were designed for 60Hz. I discovered the problem and advised management, but it was decided that I was being 'alarmist'. The first unit burnt out within 2 weeks of being installed, filled a large computer room with smoke, shut down a call centre and caused great deal of embarrassment for all. After this, management listened when I said there was a problem!

Part of the design process for a transformer is to ensure that there are enough primary turns to prevent the steel core from saturating. This depends on the voltage and the frequency. If the frequency is reduced (and 10Hz or 16.6% makes a big difference), there are no longer sufficient turns to prevent saturation. When the core saturates, the primary winding of the tranny draws much more current from the mains than normal - not just 16% more though, it can easily exceed 100% more.

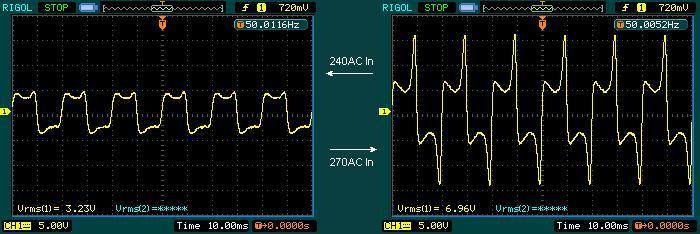

The result is that the transformer overheats, and will eventually fail. Even most technicians will be unable to tell you that the transformer is saturating, because they either don't know what to look for, or don't have the equipment needed to look at the current waveform. There is actually no difference between decreasing the frequency or increasing the voltage by the same ratio. This is shown in Figure 3, where the voltage was increased from 240V to 270V - a mere 12.5% change.

Figure 3 - Magnetising Current at 240V and 270V

The oscilloscope shows voltage, but this is the output from a current transformer. At 240V, magnetising (idle) current is 32.3mA (which reads as 3.23V RMS), and the transformer will dissipate about 7.7W. A 12.5% increase to 270V increases the magnetising current to 69.6mA, or 18.8W - well over twice the normal idle current and power. Reducing the frequency by 12.5% will have almost exactly the same effect. Any transformer designed specifically for 60Hz will draw far more idle current than normal at 50Hz [2].

Since many modern products will already be operating right at the very limits (smallest possible transformer, etc.), a reduction of mains frequency will almost certainly push them beyond the point where failure is inevitable. It's no longer a matter of 'if' it fails, but 'when'. Large 60Hz transformers may also growl with a 50Hz supply, and this can be loud enough to make a hi-fi amp unusable because of the mechanical noise. Electrical noise is also possible (i.e. noise from speakers), because stray magnetic flux can become a major problem because the core is saturated.

There is no cure for the above-mentioned issues, other than replacing the power transformer with a 50Hz version. The replacement will be expensive - assuming that the transformer is even available from the manufacturer. If not, you have an expensive paperweight that's of no use to anyone. It might be possible to operate the transformer from a lower voltage to avoid damaging saturation, but this approach cannot be recommended because it often leads to quite unacceptable consequences - serious loss of power (for an amplifier), internal supply voltages that are no longer regulated, etc., etc.

Note that operating a transformer designed for 50Hz mains at 60Hz reduces the idle current and power, so the transformer should run a little cooler. Therefore, products that are designed for 50Hz operation (destined for anywhere in the world apart from the US and Canada) will rarely have a problem with mains frequency, provided the supply voltage is correct. Inadequate design can still cause failure though.

Appliances that use motors cause additional problems. While 'universal' motors (as used in power drills, most blenders and other small appliances, vacuum cleaners and the like) don't care about the frequency at all, the same is not true of induction motors. Induction motors are used in some (mainly older) washing machines, clothes dryers, bench drills, grinders, air compressors and many other products. A 60Hz induction motor will draw more current and run slower with 50Hz mains, and of course the opposite is true of motors designed for 50Hz. In general it's best never to consider using imported equipment that uses an induction motor designed for a different voltage or frequency. Likewise, kitchen appliances are usually subject to rigorous country (and mains supply voltage) specific electrical safety tests, so moving them from one country to another is not usually a good idea.

For larger induction motors, the sheer size of the transformer needed is usually enough to turn most people off very quickly. A motor may draw 6-10 times its rated current when started, and considering that single phase motors are readily available up to 2kW (sometimes more), that means a mighty big (and expensive) transformer. A 2kVA transformer would normally be used for a 2kW motor, because there is no real need to allow for poor power factors or non-linear current. An induction motor running at full load has a very good power factor, so VA and Watts are fairly close.

Remember though - using a 60Hz motor at 50Hz will result in excessive current, lower speed and significant power loss. To convert from kW to HP (horsepower), divide power in kW by 0.746, so a 2kW motor is about 2.7 HP. Multiply HP by 0.746 to get kW.

Synchronous clocks and timers will usually run at different frequencies once the voltage is correct, but will either gain 20% or lose 16.6% - neither is useful.

Many new products of all types use switch-mode power supplies (SMPS) because they are efficient, cheap, light and can be truly universal. This must not be taken to mean that they are universal, because this is not necessarily the case. Some require a switch to change from the low range (100-130V) to the high range (200-250V), while others will work happily regardless of the input voltage. Even with switchmode supplies, some products that are exclusively for the US market may use a SMPS, but it may be low-range only! It is sometimes possible to modify the circuit to convert the supply to a higher or lower voltage, but this requires a technician with a lot of experience with these supplies. One small mistake will cause the power supply to self destruct, often in a spectacular fashion.

The common types of SMPS do not normally care about the frequency, so in general no precautions need to be taken if the frequency is changed.

There is one small problem though - many manufacturers do not disclose the type of power supply used, so you don't know if it uses a transformer or a SMPS. Most of the latest gadgets (IT products, LCD and plasma TV sets use switchmode supplies, but the product itself may not be compatible. TV sets are mostly multi-mode now, but earlier types would only work with the exact same transmission system for which they were designed. There are still many incompatibilities, so purchasing any TV or digital radio related product from overseas may be a complete waste of money.

This term is common in the US (where it originated), but there the risk is marginally less compared to what can happen with 230V mains. Never has an electronic part been more appropriately named, and it is imperative that it be removed - regardless of where you live and your local mains voltage. I can't even begin to imagine how anyone cannot (or will not) understand just how dangerous this component can be. Expect to find the death cap in any piece of audio equipment fitted with a non polarised 2-wire mains cable. All such equipment should be converted to a 3-wire cable and plug. Maintaining authenticity of vintage equipment must take a back seat to safety - always!

While the death cap is mainly found in guitar amplifiers, many valve (tube) hi-fi amps also used it, although the switch (see Figure 4) was not included. The topic is too important to ignore because of the roaring trade in vintage gear at on-line auctions. Much has been written about the 'death cap', but it has to be understood that even if an amplifier is used only in the country of origin (the US or other 120V country) it should still be removed, or replaced with a Y-Class capacitor. There are some potential problems, and although in general usage it's uncommon for the cap to create a life-threatening condition at 120V it is still the wrong type of capacitor to use from mains to chassis. Worldwide regulations stipulate that the only capacitor that is permitted to bridge the insulating barrier is a Y-Class type. Anything else is placing your (or someone else's) life at risk.

The situation is very much worse when the amp is used on 230V supplies, whether through an external transformer or otherwise. Anyone who claims otherwise is simply wrong - DC rated film capacitors cannot be used at 230V AC because they are not designed to withstand the dielectric stresses of continuous AC with alternating peaks of ±325V or more.

Figure 4 - Normal US Wiring and Correct Wiring of Mains Input

The problem is the capacitor itself. While some later amps use a UL listed capacitor, it's still only a 600V DC cap, and it will fail at 230V. For 230V AC mains, the only capacitor type that can legally be used for this application (active or neutral to earth) is the Y-Class. These capacitors are specially designed to withstand AC voltage and to fail-safe. A normal plastic film DC cap used at 230V AC can easily (and most likely) fail short-circuit ... decidedly unsafe, and likely to be deadly if the chassis is not properly earthed via the mains lead and wall outlet. Capacitor failure can lead to the liberation of noise and smoke - hopefully from the capacitor and not the guitar player!

Figure 5 - Typical Death Cap, 1950s Era

For use within the US, it's obviously up to the individual owner to decide on whether to rewire an old amp as shown above, or to leave it alone. The US regulations seem to be fairly lax - allowing a DC cap to connect from live to chassis, with no mandatory earth (ground) connection is really not a good idea. My recommendation is to rewire the amp with a 3-core cable and a 3-pin earthed mains plug. Anything else is simply too dangerous.

If the amp is used in a 230V country with an autotransformer, the likelihood of serious injury or death is very much greater. It's not (and never was) a major safety issue with a normal 120V AC supply, although there are still some very real risks documented on the Net. There are also as many anecdotal stories about 'near death' experiences as there are stories that it's just a ploy for amp technicians to make more money. Personally, I think it's a really bad idea, and if I owned an amp with a death cap fitted it would be modified and converted to 3-wire immediately, regardless of the mains voltage.

When used outside of the US and from 230V mains supplies, amplifiers that include the 'death cap' must be rewired as shown in Figure 4. The cap and switch are removed from the circuit (the switch can remain in position on the chassis though), and the original 2-core mains lead must be replaced with a 3-core lead and an earthed plug. Once this is done, even an incorrectly wired autotransformer cannot create an unsafe condition - provided that the earth connection is robust and continuous from input to output. However, this does not mean that any old autotransformer can be used - all previous recommendations still stand. In particular, use a transformer with isolated windings. It may cost a bit more, but compared to a human life it's peanuts.

The death cap can be found in a great many US amplifiers outside the US, including some export models. Any amplifier so fitted should be modified forthwith - while the cap may have failed long ago, it's simply not worth the risk of leaving it in position. If the cap hasn't failed, that doesn't mean that it won't, and you don't want to be on the receiving end of 230V mains under any circumstances.

The only reason that the death cap was ever installed in the first place, was because most early US power installations did not use earthed 3-pin outlets, and most were not polarised. The switch allowed the player/user to select the position that gave the least hum and noise - this meant the cap almost invariably connected to the neutral, and saved the 'effort' of removing the mains plug and turning it around. Polarised mains connectors or other (possibly earthed) equipment connected to the amp could easily leave the cap connected to the live 120V lead. When the chassis is earthed, the switch makes no difference, so could be connected to active or neutral with no-one the wiser.

Death caps must be removed, 2-wire non polarised mains leads and plugs removed and replaced with a proper 3-wire lead (with earth/ground securely connected to chassis) and 3-pin plug. This is doubly critical when there is the slightest chance that the voltage might be 230V instead of the relatively benign 120V AC. As long as it remains in circuit, the death cap has every opportunity to live up to its name.

First and foremost, avoid auto transformers. Make certain that the step-up/down transformer that you select has separate primary and secondary windings, is earthed properly, and has a VA rating of about double the maximum expected power drawn by the appliance. As described above, this may not be necessary, but is usually a good idea for most products.

Regarding the possible importance of frequency, it depends a great deal on the product and how it was originally designed (with/without a safety allowance for example). I would have liked to show the difference in idle current by changing the frequency, but unfortunately it requires a great deal of time and effort to set up. If anyone doesn't believe that the results shown here are real, then feel free to ignore this article in its entirety. You might be lucky, you might not. It is important to understand that some products will tolerate a lower frequency while others will not, and it's not usually possible to know beforehand those that will survive and those that won't. This can generally only be determined by testing the product.

There is no simple answer to the common question "Can you make it work?", when someone wants to know if it's alright to import product 'X' from overseas. There are simply too many possibilities for anyone to give a definitive answer - guesses are just that, and cannot be relied upon. This is especially true if the imported equipment is expensive and the seller doesn't know enough to be able to provide useful answers. In such cases, it may be better to avoid the item altogether because the cost of modification may make it more expensive than the same thing purchased locally.

There are some products (especially vintage), where modifications are simply not an option because they will devalue the item. In such cases, the best you can do is hope that it will be alright. Otherwise it becomes a rather expensive display product that can't be used.

For those for whom money is no object, motor-alternator units can be purchased (they are no longer as common as they once were though), or high-power electronic frequency and voltage converters also exist. These units range from a few hundred Watts to many kW, but are typically very expensive ... the mere fact that suppliers seem to never publish any prices gives you a good idea of the price range [3].

Main Index

Main Index

Articles Index

Articles Index